The Features and Diverse Applications of FR5 Epoxy Glass Fiber Laminates

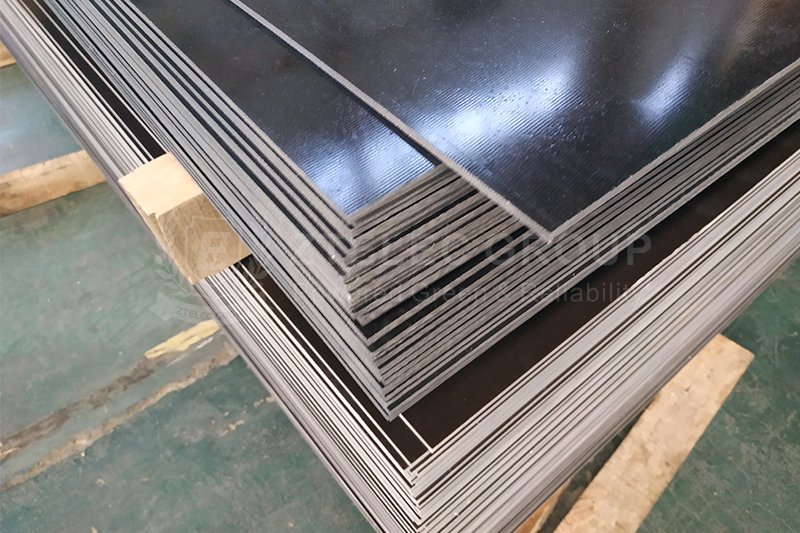

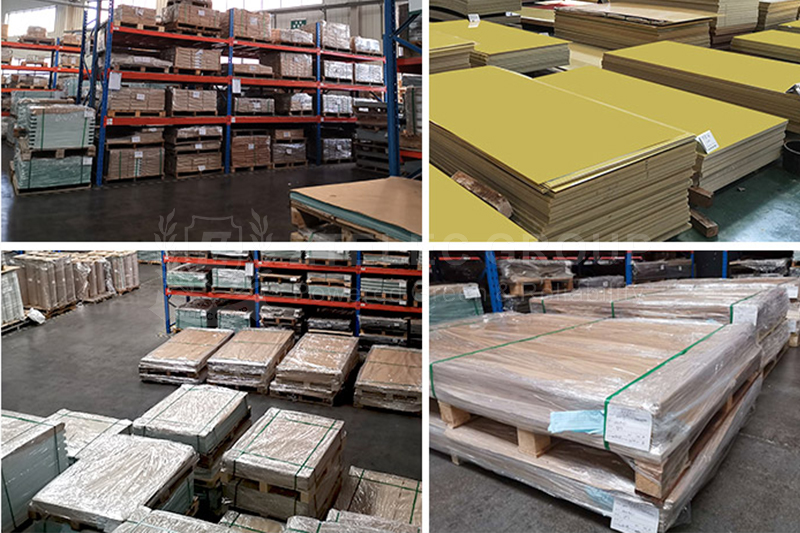

FR5 epoxy glass fiber laminates are laminated materials formed by the composite of epoxy resin and glass fiber cloth under high temperature and high pressure. With excellent properties such as good insulation, high strength, high temperature resistance, and corrosion resistance, it holds an important position in the industrial field. With the progress of science and technology, the application boundaries of this material are constantly expanding, bringing new possibilities to many industries.

Features of FR5 Epoxy Glass Fiber Laminates

Excellent Electrical Insulation Performance

FR5 epoxy glass fiber laminates have high insulation resistance and breakdown voltage, which can effectively isolate the risks of current leakage and breakdown, and build a reliable insulation protection for electronic devices. Its low dielectric constant and dielectric loss factor can reduce signal attenuation in high-frequency circuits and ensure the stable transmission of signals, making it an ideal choice for high-frequency electronic devices.

Good Mechanical Properties

This material has both high strength and high stiffness, and can withstand large external forces and pressures without being easily deformed. At the same time, it also has a certain degree of toughness and impact resistance. When encountering external impacts, it can protect the internal electronic components from damage and ensure the structural integrity of the equipment.

Outstanding Thermal Stability Performance

FR5 epoxy glass fiber laminates have a high thermal deformation temperature and can still maintain stable performance in a high-temperature environment. This characteristic enables it to be widely used in electronic devices with strict temperature requirements, meeting the usage needs under special working conditions.

Strong Chemical Corrosion Resistance

Whether facing acids, alkalis, or chemical substances such as salts, FR5 epoxy glass fiber laminates show extremely strong corrosion resistance. Even in a harsh chemical environment, it can maintain stable performance,which significantly extends the service life of the equipment.

Application of FR5 Epoxy Glass Fiber Laminates

The Electronic Manufacturing Field

In the electronic manufacturing industry, FR5 epoxy sheets are key materials for the manufacturing of high-frequency PCBs. Due to its characteristics of low dielectric constant and low dielectric loss, it is particularly suitable for high-frequency application scenarios such as 5G communication devices, radar systems, and radio frequency modules. In the field of automotive electronics, its excellent high-temperature resistance makes it a commonly used material for core components such as engine control units (ECUs) and battery management systems (BMSs) for new energy vehicles. With the vigorous development of the electric vehicle market, the application prospects of FR5 are becoming increasingly broad.

The Power Industry

The power industry is an important application field for FR5 epoxy boards. In transformers, high-voltage switchgear, and motor insulation systems, it provides reliable insulation solutions. With excellent high-temperature resistance and mechanical strength, it ensures the long-term stable operation of power equipment. In special environments such as offshore wind power platforms and high-temperature industrial sites, its weather resistance and chemical corrosion resistance further highlight its advantages, making it the preferred material to ensure the safe operation of power facilities.

The Aerospace and Defense Fields

The aerospace field has extremely high requirements for material performance. FR5 epoxy sheets are widely used in aircraft electronic control systems and satellite communication equipment due to their characteristics of light weight, high strength, and resistance to extreme temperatures. In the defense industry, its stability and reliability meet the stringent requirements of missile guidance systems and military electronic devices, further confirming its excellent quality as a high-performance insulation material.

With the rapid development of 5G technology, the Internet of Things, and the industry, the market demand for FR5 epoxy sheets continues to rise. In the future, the research and development of environmentally friendly FR5 materials will become the focus of the industry. Halogen-free and recyclable products are more in line with the trend of global environmental protection regulations. For purchasers, choosing high-quality suppliers certified by standards such as UL and IEC can ensure that the material performance meets the application requirements. In-depth understanding of the characteristics and applications of FR5 helps enterprises to fully utilize the value of this high-performance material and enhance the competitiveness of their products.

- more+releated article

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-12Price of a 1600kVA 10kV Cast Resin Dry-Type Tr

- 2025-12-12How to Choose Epoxy Laminate Materials for Gen

- 2025-12-11Protection Configuration Principles for 35kV D

- 2025-12-11The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-10Application Prospects of 10kV/35kV Oil-Immerse

- 2025-12-09How to Reduce the Maintenance Cost of Oil-Imme

- 2025-12-09How to Choose the Best 110 kV Oil-Immersed Pow

- 2025-12-08Heat-Resistant DDP Insulation Paper