How to Choose Epoxy Laminate Materials for Generators?G10, FR4, and G11

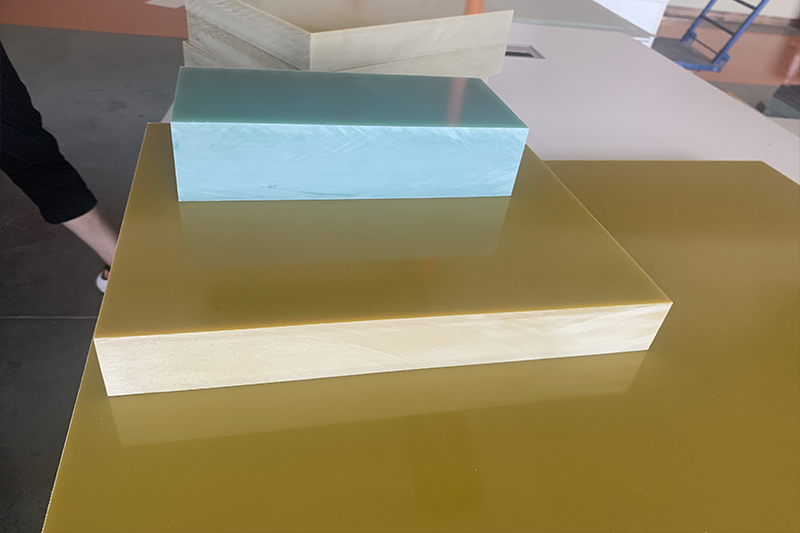

In generator and electrical equipment manufacturing, the selection of epoxy laminate materials directly affects equipment performance, service life, and operational safety. G10, FR4, and G11 are three commonly used epoxy sheet materials. Although they look similar, their core properties differ significantly. This article provides a detailed comparison of these materials and their suitable application scenarios, offering technical guidance for selecting epoxy sheets used in generators.

Role of Epoxy Sheets in Generators

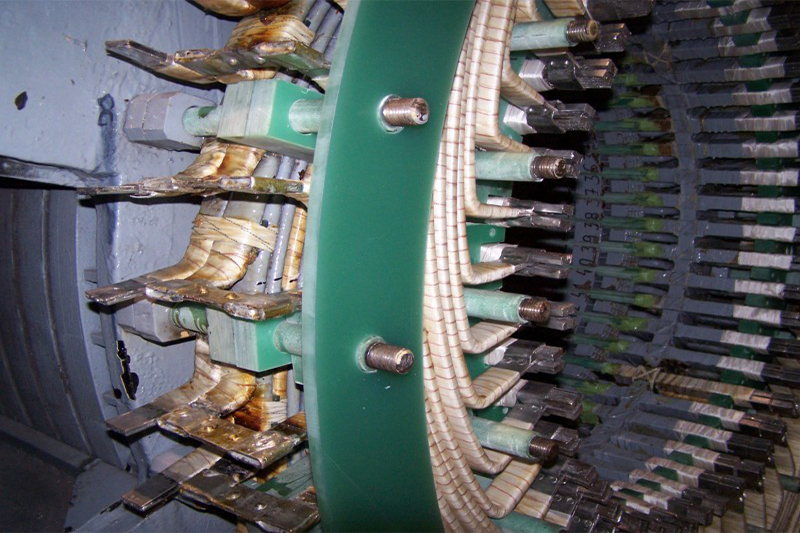

Epoxy laminates serve several essential functions inside generators:

Electrical Insulation: Provide physical isolation between live parts to prevent short circuits.

Structural Support: Offer mechanical support and fixation for coils, windings, and other key components.

Thermal Stability: Maintain stable performance under high-temperature operating conditions.

Environmental Protection: Resist moisture ingress, chemical corrosion, and physical abrasion.

Performance Differences Among G10, FR4, and G11

1. Thermal Resistance

G10 and FR4 generally have a heat resistance rating of 130°C, corresponding to Class B insulation.

G11 offers heat resistance up to 150°C or above, classified as Class F insulation. It is suitable for generators operating under high speed, heavy load, or high-temperature conditions.

2. Flame Retardancy

FR4 meets the UL94 V-0 flame-retardant standard and provides reliable fire safety.

G10 is non-flame-retardant, making it unsuitable for applications with mandatory fire-resistance requirements.

G11 can be customized into flame-retardant versions based on project needs.

3. Electrical Insulation Performance

All three materials offer excellent electrical insulation, but their advantages vary:

FR4 has the most stable insulation performance, especially in environments with temperature and humidity fluctuations.

G10 features very low water absorption, but due to its non-flame-retardant nature, safety evaluation is required for generator applications.

G11 maintains strong insulation performance under high temperatures, making it ideal for high-temperature generator models.

4. Mechanical Strength

G10 delivers the highest mechanical strength among the three, making it suitable for:

Generator components with high mechanical loads

High-vibration working environments

Complex structural support inside generators

However, G10 must not be used in applications that require flame-retardant materials.

Application Scenarios of G10, FR4, and G11 in Generator

1. FR4 epoxy board

Insulation components for small and medium-sized generators

Power generation equipment in mild operating environments

Projects with strict cost control

Standard electrical isolation boards

2. G10 epoxy board

Core components of medium and high-temperature generator sets

Applications with high requirements for mechanical strength

Insulation structural components for industrial generators

Generator slot wedges, spacer sheets, and end support parts of windings

3. G11 epoxy board

High-temperature generator sets (gas turbine generators, steam turbine generators)

Heavy-duty industrial generators

Power generation equipment in harsh operating environments

Insulation components for critical parts of generators

How to Choose the Right Epoxy Board for Generators?

1. Evaluate Working Temperature

Working temperature below 130℃: FR4 is preferred

Working temperature between 130℃ and 140℃: G10 can be used

Working temperature above 150℃: G11 should be selected

2. Analyze Mechanical Properties

Conventional support components: FR4 or G10 can be used

Components with high mechanical stress: G10 or G11 should be selected

High-frequency vibration conditions: G10 or G11 (both have better fatigue resistance)

3. Consider Environmental Conditions

Conventional indoor conditions: FR4 can be used

High humidity or chemical medium erosion environment: G10 or G11 should be selected

Outdoor or harsh working conditions: G11 should be selected

4. Balance Budget and Performance

Cost priority projects: FR4 can be used

Standard industrial-grade generator equipment: G10 should be selected

Critical or high-end generator equipment: G11 should be selected

The performance and cost of three types of epoxy boards are distributed in a gradient:

FR4 is economical and practical, suitable for low-temperature working conditions.

G10 can achieve a balance between mechanical performance and procurement cost.

G11 is the best choice for high-temperature and harsh working conditions.

A scientific selection of epoxy laminate sheets must be based on a comprehensive analysis of the generator’s actual operating conditions. Key factors include defining the temperature range, mechanical load, environmental conditions, and budget scope. When selection uncertainties arise, choosing higher-grade materials is recommended to reduce the risk of failure. From a cost-effectiveness perspective, the optimal choice is an insulation material that precisely matches the specific application requirements.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen