G10 and FR4 Epoxy Boards: Commonly Used for Generator Maintenance

In modern industrial and energy systems, generators are core equipment that ensure stable power output. As operating hours increase, the internal insulation materials of generators gradually age due to temperature, vibration, moisture, and electrical stress. To ensure operational safety, stability, and extend the service life of generators, high-performance insulation materials are essential. G10 and FR4 epoxy sheets, known for their excellent insulation properties and mechanical strength, have become indispensable materials in generator maintenance and repair.

Overview of G10 and FR4 Epoxy Sheets

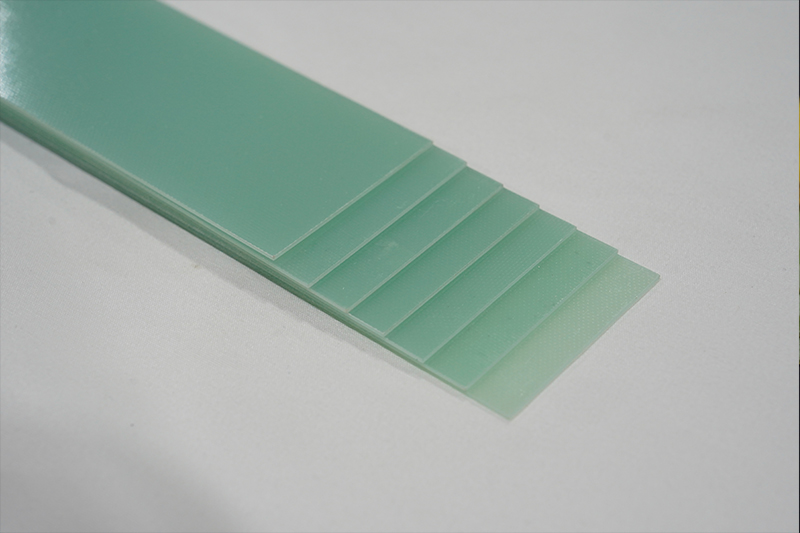

1. G10 Epoxy Sheet

G10 epoxy sheet is an insulation material made by impregnating fiberglass cloth with epoxy resin and laminating it under high temperature and high pressure. Its specifications were originally defined by NEMA (National Electrical Manufacturers Association) standards. This material offers excellent mechanical strength, electrical insulation, and moisture resistance. In generator maintenance, it is commonly used for manufacturing insulating spacers, support components, and isolation parts.

2. FR4 Epoxy Sheet

FR4 epoxy sheet is the flame-retardant modified version of G10. By adding flame-retardant agents (typically brominated compounds), it can meet the UL94 V-0 flame-retardant standard. FR4 maintains the outstanding physical and electrical properties of G10 while offering enhanced fire safety. This feature is especially valuable during generator operation and maintenance. Compared with G10, FR4 epoxy sheet is better suited for generator applications where flame-retardancy is strictly required.

Core Functions of G10 and FR4 Epoxy Sheets in Generator Maintenance

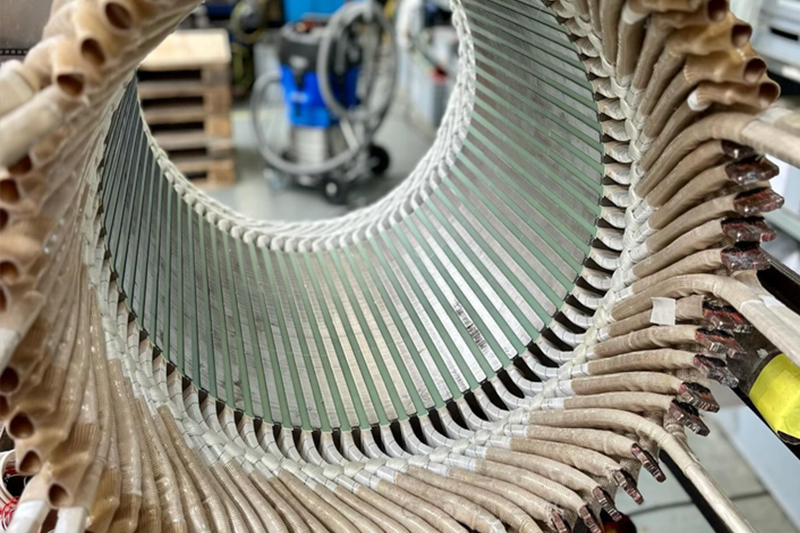

1. Slot Wedges

G10/FR4 epoxy sheets are widely used as stator slot wedges in generators. Their main functions include:

Securing the stator coils and preventing displacement caused by equipment vibration

Ensuring uniform stator air gap and improving generator efficiency

Enhancing internal structural stability and improving electrical operational safety

2. Phase-to-Phase Insulation

Generators operate with multi-phase power systems that require proper insulation barriers. With their high dielectric strength, G10/FR4 epoxy sheets effectively prevent:

Phase-to-phase short circuits in the generator

Partial discharge within the equipment

Insulation breakdown between coils

3. Blocks and Support Structures

Thanks to their high mechanical strength and good thermal resistance, G10/FR4 epoxy sheets can be used to manufacture:

Coil support blocks

Reinforcement supports for generator end windings

Vibration-absorbing components

These applications improve the generator’s vibration resistance and help extend overall equipment lifespan.

4. Insulating Barriers

They can be used to optimize electric field distribution inside the generator, preventing electrical arcing and the formation of local hot spots.

5. Maintenance Replacement Parts

During routine generator maintenance, the following aged or degraded insulating components must be replaced regularly:

Aged slot wedges

Deformed insulating barriers

Hydrolyzed or carbonized insulation parts

G10/FR4 epoxy sheets are internationally recognized as reliable insulation replacement materials.

G10 and FR4 Epoxy Sheet Selection Guide

1. When to Choose G10 Epoxy Sheets

The application does not require strict flame-retardant performance.

Maximum mechanical strength is required.

Maintenance projects are cost-sensitive and have lower fire-safety requirements.

The operating environment has high humidity (G10 features extremely low moisture absorption).

2. When to Choose FR4 Epoxy Sheets

The generator is installed in areas with high fire-risk.

The application must meet stringent fire-safety regulations.

The project specifically requires UL-certified insulation materials.

Machining and Installation Guidelines

1. Machining Tips

Use carbide or diamond tools for cutting operations.

For drilling, adopt a low-speed, high-feed process to prevent delamination.

Sand the material’s surfaces and edges to ensure smoothness and reduce the risk of electrical discharge.

2. Installation Notes

Clean the mounting surfaces before installation to ensure they are free of oil, dust, and other contaminants.

Control the tightening force during fastening to avoid cracking caused by excessive torque.

Monitor temperature and humidity to ensure compliance with the material’s installation requirements.

Verify compatibility between G10/FR4 epoxy sheets and other internal generator materials in advance.

G10 and FR4 epoxy sheets, with their outstanding insulation properties, mechanical strength, and weather resistance, have become the most widely used and highly reliable insulation materials in generator maintenance. Whether for slot wedges, insulating barriers, phase insulation, or structural supports, these materials effectively enhance the operational stability and safety of generator.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen