Price of a 1600kVA 10kV Cast Resin Dry-Type Transformer | Market Insights & Buying Guide

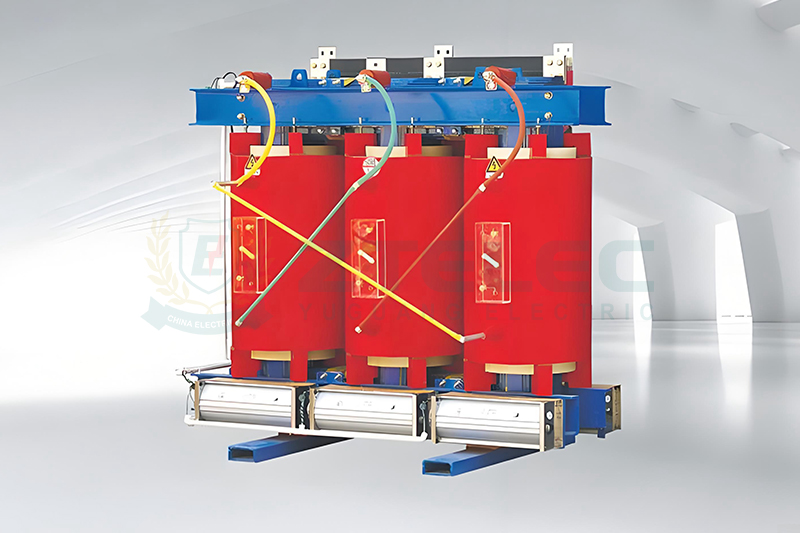

As power construction and new energy projects continue to expand, the 1600kVA 10kV cast resin dry-type transformer has become a mainstream choice for commercial buildings, factories, public facilities, and renewable energy grid-connection systems. Its stable performance, high safety level, and maintenance-free design make it especially suitable for modern power distribution applications.

For many project owners, the most frequently asked question remains: “What is the price of a 1600kVA 10kV cast resin dry-type transformer?” Below is a practical breakdown based on current market trends.

Price Range of a 1600kVA 10kV Cast Resin Dry-Type Transformer

At present, the market price of a 1600kVA 10kV dry-type transformer typically falls between:

120,000 – 220,000 RMB (reference range)

The final quotation varies from supplier to supplier. Premium brands, high-efficiency models, imported insulation systems, and customized specifications often fall at the upper end of the price range, while standard configurations cost less.

What Determines the Transformer Price?

1. Coil Material

The choice between copper and aluminum significantly affects cost. Copper coils offer better conductivity but cost more, and fluctuations in global metal prices can directly influence transformer quotations.

2. Energy Efficiency Level

Models such as S11, S13, and low-loss European-standard transformers differ greatly in loss performance. Higher-efficiency models help reduce long-term operating costs but require more investment upfront.

3. Resin Casting Technology

Transformers using high-quality imported resin, vacuum pressure casting, or advanced anti-partial-discharge insulation systems come with higher production costs, which reflect in the price.

4. Brand Strength & Certifications

Products with CE, KEMA, TÜV, ISO, or IEC certifications generally have more stable quality and better long-term performance, and naturally cost more.

5. Additional Protection & Monitoring Functions

If your project requires intelligent temperature control, forced-air cooling, or real-time monitoring, the overall price will increase accordingly.

Main Advantages of Cast Resin Dry-Type Transformers

1. High Safety Level

Dry-type transformers are oil-free, flame-retardant (F1 rating), and designed to operate safely even in humid or dusty environments. The resin-encapsulated windings also comply with international standards such as IEC 60076 and GB 1094.11.

2. Excellent Energy Efficiency & Long Service Life

Newer SCB18 models reduce no-load losses by up to 20% compared to SCB13. Most units have a service life exceeding 25 years and require minimal maintenance, making them cost-effective over the long term.

How to Reduce Procurement Costs?

1. Identify Application Requirements First

Clarifying installation environment, system voltage, cooling conditions, and expected load can help avoid unnecessary upgrades or mismatched specifications.

2. Avoid Over-Configuration

A transformer with excessive efficiency or protection functions may not provide additional value for your project. Choosing a reasonable specification saves significant costs.

3. Stabilize Raw Material Pricing

Copper, aluminum, and resin prices change frequently. Locking in material prices in advance can minimize unpredictable cost increases.

4. Purchase Directly from Manufacturers

Direct sourcing eliminates distributor markups and ensures faster delivery, more stable quality, and better after-sales support.

Where Can a 1600kVA 10kV Cast Resin Dry-Type Transformer Be Used?

Typical application scenarios include:

Commercial centers

Hospitals and educational campuses

Factories and industrial plants

Photovoltaic and wind power grid-connection systems

High-rise building distribution rooms

Because dry-type transformers do not use oil and have excellent fire resistance, they are ideal for areas with strict environmental and safety regulations.

Professional Suggestions for Procurement

When evaluating the price of a 1600kVA cast resin dry-type transformer, it’s important to consider more than just the initial purchase price. A reliable procurement decision should include:

Reviewing type test reports

Visiting the manufacturer or inspecting the production line

Comparing long-term operating and maintenance costs

Confirming warranty terms and service capabilities

With a well-planned selection strategy, companies can ensure stable power supply while keeping long-term project costs under control.

If you need a quotation, technical consultation, or customized transformer options, feel free to contact us at any time.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen