The Price of Heat-Resistant DDP Insulation Paper:Five Key Factors Affecting Price

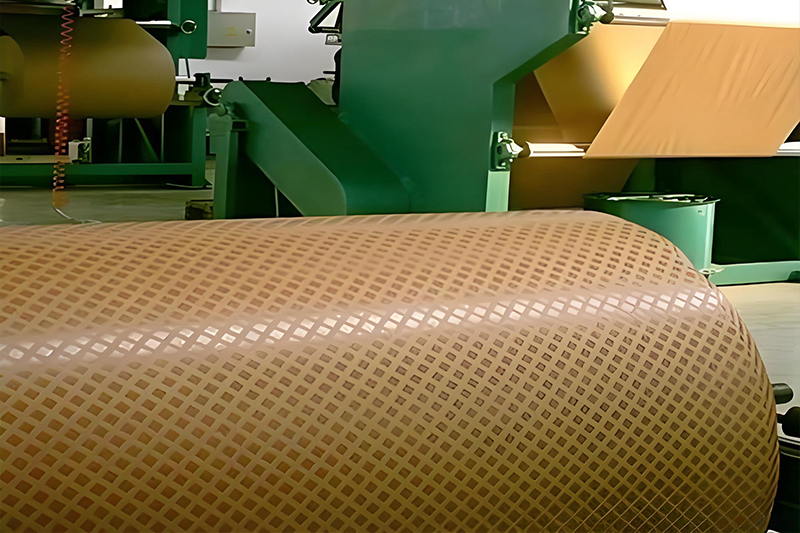

Heat-resistant DDP insulation paper (Dotted Diamond Paper) offers excellent thermal resistance, mechanical strength, and oil-impregnation performance. It has been widely used in oil-immersed transformers, instrument transformers, reactors, and other electrical equipment. With the global energy transition and the accelerated development of power grid construction, the market demand for DDP insulation paper continues to grow. This article analyzes the pricing logic of DDP insulation paper from five dimensions: resin system, thickness, thermal class, processing technology, and market conditions.

1. Resin System

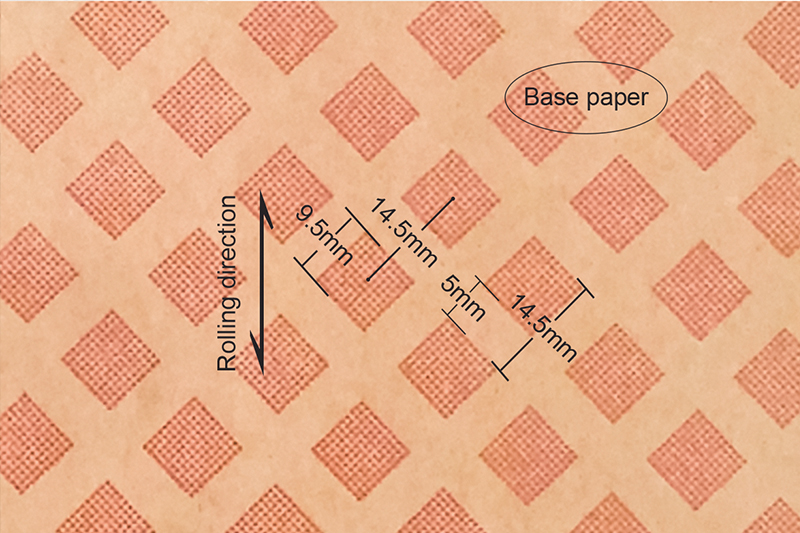

The diamond-shaped dotted resin coated on the surface of DDP insulation paper is the core component that ensures product performance, and it is also one of the main contributors to price differences.

Common Resin Systems:

♦ Conventional thermosetting resin (economic type):

Suitable for 105°C–120°C class electrical equipment. And it has relatively low material and processing costs.

♦ Modified epoxy resin system (mainstream type):

Provides higher mechanical strength and bonding capability. And it meets the application needs of mainstream oil-immersed transformers.

♦ High-temperature resin system (H-class, C-class, premium type):

Mainly used in EV drive systems, reactors, and high-power transformers. The price is significantly higher than that of standard resin systems.

The higher the technical grade and thermal resistance of the resin system, the higher the material and manufacturing cost—ultimately resulting in a higher final product price.

2. Thickness

Thickness is a fundamental parameter of DDP insulation paper and a key factor affecting its price.

Standard thickness:

Common specifications include 0.13 mm, 0.18 mm, and 0.25 mm. The greater the thickness, the more base paper and resin are required per unit area, increasing production costs.

Thickness tolerance:

High-performance applications require strict thickness tolerance control, such as within ±0.01 mm. This raises the difficulty of coating, curing, and other production steps, resulting in higher costs.

Composite structure:

Some applications require multilayer composite insulation paper. This increases both material consumption and processing steps, further raising total costs.

When meeting electrical clearance and creepage distance requirements, it is advisable to select economical thickness specifications and verify whether the thickness tolerance matches the precision requirements of the equipment.

3.Heat Resistance Grade

The heat resistance grade is the core technical indicator that determines the price of DDP insulating paper.

Common heat resistance grades:

Class A (105℃): Suitable for traditional low-temperature oil-immersed power equipment.

Class E/B/F (120℃–150℃): The current mainstream application grades in the market.

Class H (180℃): Suitable for high-power equipment, electric vehicle drive systems, reactors, and other products.

Class C (≥200℃): Applied in ultra-high-end special power equipment fields.

The higher the heat resistance grade of insulating paper, the more stringent the technical requirements for the base paper material and resin performance, and the corresponding production and manufacturing costs will also increase accordingly.

4.Processing Technology and Technical Standards

For DDP insulating paper with the same basic specifications, the price difference between products from different manufacturers can reach 20%–40%. The core reason lies in the differences in the processing capabilities and quality control levels of each manufacturer. The specific influencing factors are as follows:

Uniformity of resin coating. Avoid problems such as missed coating and coating thickness deviation.

Degree of resin curing. Inadequate curing will directly reduce the bonding strength of the insulating paper.

Position accuracy and standardization degree of diamond-shaped dot patterns.

Surface cleanliness of insulating paper. Control defects such as bubbles and impurities.

Overall flatness of the roll and precision of the cutting size.

Whether the product complies with industry standards such as IEC, GB, and IEEE.

DDP insulating paper that meets high-standard manufacturing requirements has better core performance such as oil immersion compatibility, mechanical strength, and heat resistance service life, and the corresponding product price will also be higher than that of conventional standard products.

5.Market Condition

The market price of DDP insulating paper is significantly affected by macro market factors. The specific influencing dimensions are as follows:

♦ Fluctuations in raw material prices: Especially wood pulp, resin, etc.

♦ Changes in industry demand: The scale expansion of industries such as new energy, electric vehicles, and smart grids.

♦ Environmental and energy policies: The enhancement of environmental requirements such as VOCs emission limits.

♦ Changes in international transportation costs: Tariffs, international logistics costs, etc.

Reasonable selection of DDP insulating paper can not only effectively control the manufacturing cost of power equipment but also significantly extend the overall service life of power equipment such as transformers.

If you are looking for a manufacturer of heat-resistant DDP insulating paper, please feel free to contact us at any time!

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen