Comparison of Heat-Resistant DDP Insulating Paper with NMN, DMD, and Insulating Pressboard

In power equipment and industrial motors, high-performance insulation materials are essential for safe and stable operation. Heat-resistant DDP insulating paper offers excellent thermal endurance and mechanical strength, making it the preferred material for many high-end electrical devices. This article explains the differences and advantages of heat-resistant DDP insulating paper compared with NMN, DMD, and traditional insulating pressboard.

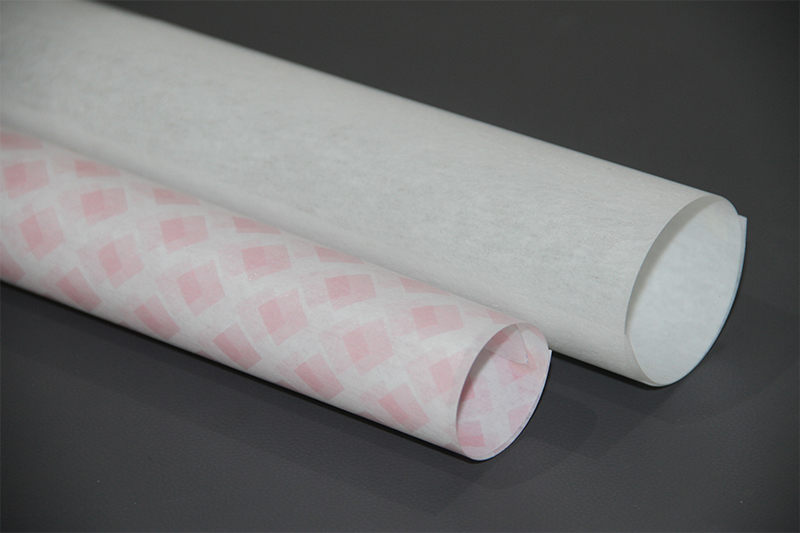

Overview of Heat-Resistant DDP Insulating Paper

Heat-resistant DDP insulating paper is high-temperature insulating paper treated with a special impregnation process. Its main features include:

High thermal resistance: Withstand operating temperatures above 150°C for extended periods.

Excellent mechanical strength: Maintains good tensile and compressive performance even in high-temperature environments.

Good electrical properties: High insulation resistance and low dielectric loss, suitable for high-voltage applications.

Chemical corrosion resistance: Resistant to oil, acids, alkalis, and moisture.

Heat-resistant DDP insulating paper is mainly used in high-performance transformers, motor windings, generators, and new energy equipment. And it is suitable for industrial high-temperature environments.

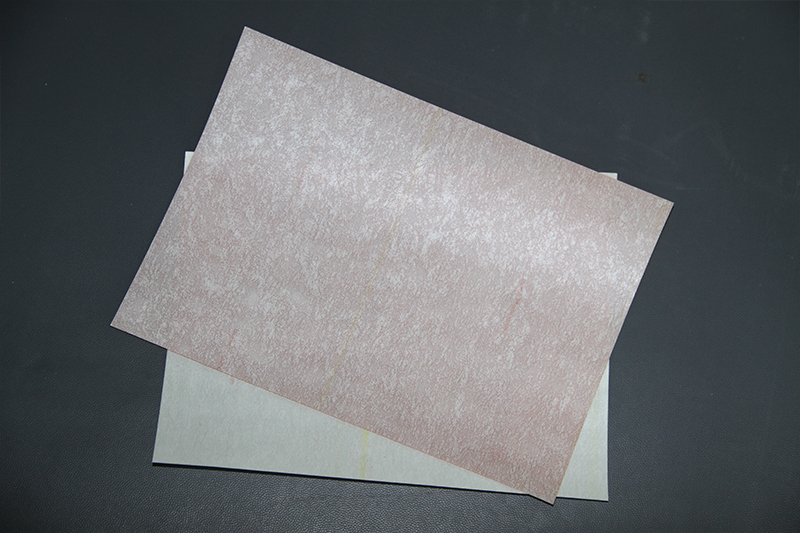

Features of NMN Insulating Paper

NMN insulating paper is an insulation material impregnated with a special resin. Its main characteristics are:

High thermal class: NMN is suitable for temperatures ranging from 150°C to 180°C.

High electrical strength: NMN is used in high-voltage equipment.

Good mechanical strength: Performance may decrease in high-humidity environments.

Compared with heat-resistant DDP insulating paper, NMN paper has lower moisture resistance and long-term high-temperature stability, but it is more cost-effective and suitable for medium-to-high temperature motors and general-purpose transformers.

Features of DMD Insulating Paper

DMD insulating paper is a special resin-impregnated paper, with the following main advantages:

Good high-temperature performance: Operate continuously around 150°C.

High mechanical strength: Suitable for high-load motor and generator windings.

Stable dielectric properties: Suitable for high-frequency and high-voltage applications.

Compared with heat-resistant DDP paper, DMD paper has lower oil resistance and chemical corrosion resistance, but it can still be used in specific high-temperature, high-voltage scenarios.

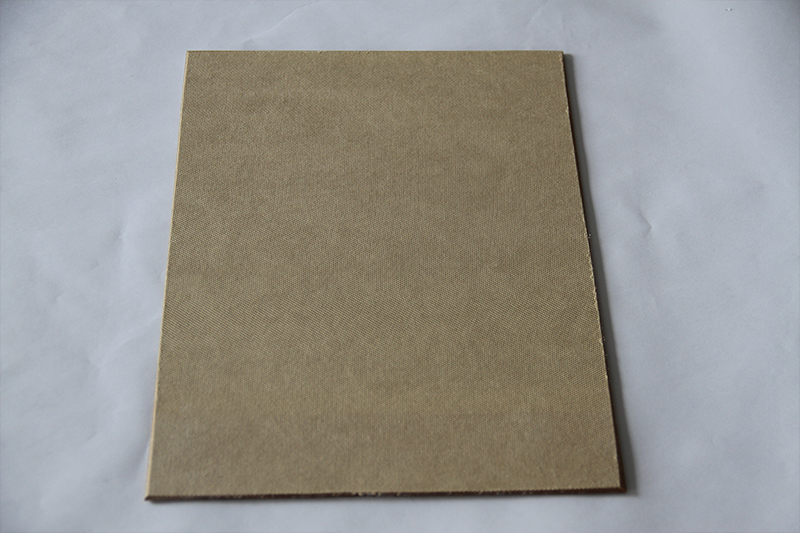

Overview of Insulating Pressboard

Traditional insulating pressboard mainly includes ordinary pressboard and oil-impregnated pressboard, with the following characteristics:

Low cost: Economical solution.

Moderate mechanical performance: Suitable for low-load equipment.

Limited thermal resistance: Suitable temperature range 90–130°C.

Insulating pressboard is mainly used in low-voltage distribution equipment, general-purpose motors, and standard industrial machinery. Its performance is lower than heat-resistant DDP, NMN, and DMD insulating papers.

Comparison of Application Areas

1.Heat-Resistant DDP Insulating Paper Applications

High-temperature motors and generator slot insulation

Traction motors and special-purpose motors

Transformer interlayer insulation

Aerospace, military, and other fields requiring extreme thermal resistance and reliability

2.NMN Insulating Material Applications

Medium-sized high-voltage motor insulation

Dry-type transformer insulation

Phase-to-phase insulation in electrical equipment

Scenarios requiring flexibility and high electrical strength

3.DMD Insulating Material Applications

Small to medium motor slot insulation

Household appliance motor insulation

Low-voltage transformer insulation

Scenarios balancing cost and overall performance

4.Insulating Pressboard Applications

Transformer insulation spacers and supports

Insulating supports for switchgear

Mechanical support components in electrical equipment

Low-voltage equipment with minimal thermal requirements

Selection Guide

Temperature conditions:

For high-temperature environments, choose DDP or NMN.

For medium temperatures, DMD is suitable.

For low temperatures, insulating pressboard can be considered.

Electrical requirements:

For high-voltage applications, DDP or NMN is preferred.

For low-voltage scenarios, DMD or pressboard is sufficient.

Mechanical requirements:

If flexibility is important, choose DDP, NMN, or DMD.

If rigid support is required, select insulating pressboard.

Environmental factors:

In humid or oil-contaminated environments, synthetic materials (DDP/NMN/DMD) are preferred.

Cost considerations:

Determine based on the balance between performance needs and budget.

Heat-resistant DDP insulating paper demonstrates outstanding performance in high-temperature, high-voltage, and high-load environments, making it widely used in new energy equipment, generators, and high-end motors. By comparing it with NMN, DMD, and traditional insulating pressboard, its advantages in thermal resistance, mechanical strength, electrical performance, and chemical corrosion resistance become clear, which provides a scientific basis for material selection in electrical equipment.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen