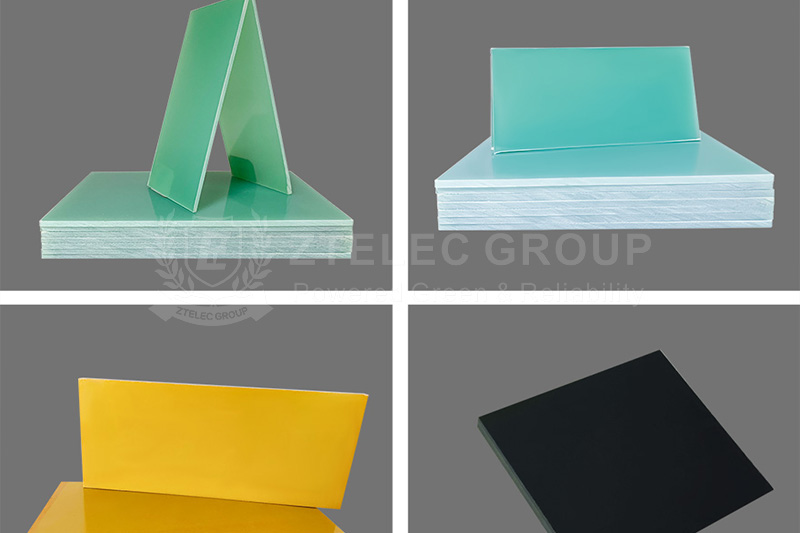

FR4 Insulation Materials: Electrical Performance,Thermal Stability And Cost Advantages

Electrical properties of FR4 insulation materials

Insulation properties

FR4 is an extremely good electrical insulator that can effectively prevent short circuits between different circuits on the circuit board. It can accurately isolate different signal paths in the circuit. Taking a multi-layer PCB as an example, the signals between layers can be isolated with the help of FR4 materials to ensure accurate signal transmission. In complex electronic devices, many circuits are densely distributed. FR4 avoids mutual interference between these circuits with its high insulation resistance.

Dielectric constant

The dielectric constant is a key indicator of the ability of a material to store electrical energy in an electric field. The dielectric constant of FR4 is in a suitable range. If the dielectric constant is too high, the signal propagation speed will slow down and the delay will increase; if it is too low, it will affect other electrical properties of the circuit board. In the field of high-frequency circuit board design, such as the PCB used in 5G communication equipment, the impact of FR4 dielectric constant on signal propagation is a factor that must be considered during design. Only with a suitable dielectric constant can high-frequency signals be efficiently and quickly propagated to meet the requirements of 5G communication for high-speed and low-latency signal transmission.

Dielectric loss factor

FR4 has a low dielectric loss factor. This feature can significantly reduce energy loss during signal transmission, especially in high-frequency circuits. A lower dielectric loss factor means that high-frequency signal transmission is more efficient and signal attenuation is greatly reduced. Taking the high-frequency circuit in satellite communication equipment as an example, it is precisely because of this feature of FR4 material that the signal can maintain high strength and accuracy during long-distance transmission, ensuring stable and reliable communication between satellites and ground stations.

Thermal stability of FR4 insulation materials

FR4 materials have high thermal stability and good heat resistance, and can be used stably for a long time in high temperature environments. When electronic equipment is running, especially high-power equipment such as server power supplies and industrial inverters, a lot of heat will be generated inside, resulting in an increase in operating temperature. In such a high-temperature environment, FR4 materials can still withstand it, and its structure and performance will not be significantly deteriorated. This feature ensures that related equipment can continue to operate stably at high temperatures, avoiding problems such as short circuits and failures caused by the degradation of insulation material performance. In electrical control equipment in high-temperature industrial environments such as steel smelters, FR4 materials can also ensure the normal operation of equipment under harsh conditions, providing support for the continuity of industrial production.

Cost advantages of FR4 insulation materials

Material cost

In the insulation material market, FR4 has a wide range of raw materials and a relatively reasonable price. The glass fiber cloth and epoxy resin that make up FR4 have large global production and stable supply. Compared with high-end special insulation materials, FR4 has a lower raw material procurement cost. In the large-scale PCB manufacturing industry, raw material cost is a key factor affecting total cost. FR4, with its lower material cost, allows PCB manufacturers to ensure product quality while effectively controlling production costs, thereby gaining a price advantage in market competition. Many consumer electronic products, such as smartphones and tablets, use FR4 materials in large quantities in PCB manufacturing because of its material cost advantage.

Processing cost

FR4 material has good processing technology and is easy to cut, drill, laminate. It is easy to process and does not require high equipment and technology. This saves manufacturers from investing high equipment purchase costs and complex technology research and development costs. In the PCB manufacturing process, the cutting and drilling processes can not only be completed efficiently, but also have a low scrap rate. Compared with difficult-to-process insulation materials, FR4 can save a lot of processing time and labor costs. In the large-scale production of electronic equipment, the reduction in processing costs directly reduces the total cost of the product and improves the market competitiveness of the product.

- more+releated article

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-12Price of a 1600kVA 10kV Cast Resin Dry-Type Tr

- 2025-12-12How to Choose Epoxy Laminate Materials for Gen

- 2025-12-11Protection Configuration Principles for 35kV D

- 2025-12-11The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-10Application Prospects of 10kV/35kV Oil-Immerse

- 2025-12-09How to Reduce the Maintenance Cost of Oil-Imme

- 2025-12-09How to Choose the Best 110 kV Oil-Immersed Pow

- 2025-12-08Heat-Resistant DDP Insulation Paper