Phenolic Materials: Properties, Applications, and Market Trends

2024-08-14 16:19 | By: ZTELEC-www.ztelecgroup.com | 84click

Introduction to Phenolic Materials

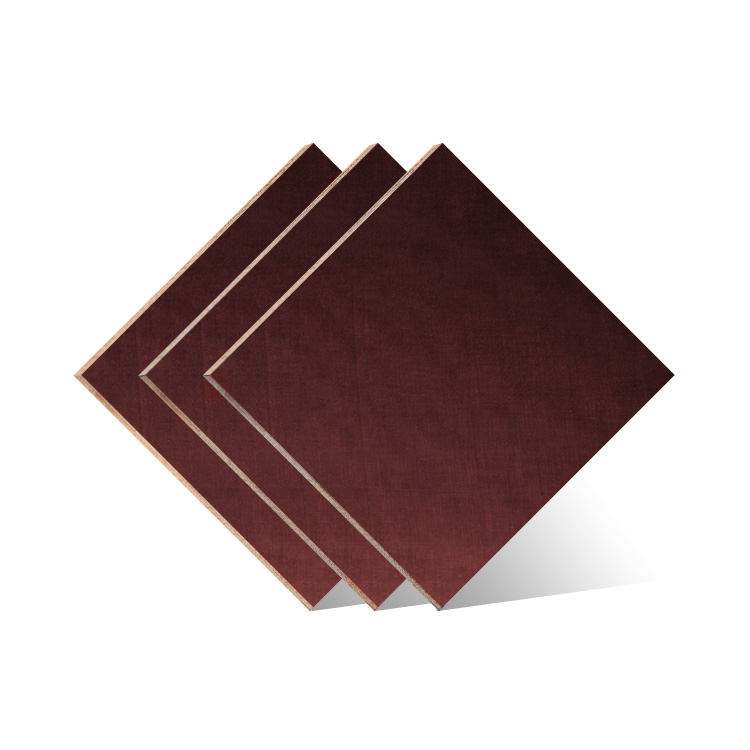

Phenolic materials, often referred to as phenolic resins or phenolics, are synthetic polymers obtained through the reaction of phenol with formaldehyde. These materials are known for their exceptional thermal stability, mechanical strength, and resistance to a wide range of chemicals, making them indispensable in various industrial applications.

Phenolic materials have been in use for over a century, with the first synthetic plastic, Bakelite, being a phenolic resin. Today, these materials are used across numerous industries, including automotive, electronics, construction, and consumer goods, owing to their versatile properties and cost-effectiveness.

Key Properties of Phenolic Materials

Phenolic materials offer a unique combination of properties that make them ideal for demanding applications:

Thermal Stability: Phenolic resins can withstand high temperatures without losing their structural integrity. This property is crucial in applications that involve exposure to heat, such as automotive parts and electrical insulators.

Mechanical Strength: Phenolics are known for their rigidity and mechanical strength. They provide excellent structural support, making them suitable for use in load-bearing applications.

Chemical Resistance: These materials are resistant to a wide range of chemicals, including acids, bases, and solvents. This makes them ideal for use in harsh chemical environments.

Flame Retardancy: Phenolic resins are inherently flame-retardant, meaning they do not catch fire easily and can help in containing the spread of flames.

Electrical Insulation: Phenolic materials are excellent electrical insulators, making them ideal for use in electrical and electronic components, such as circuit boards and switchgear.

Dimensional Stability: Phenolics maintain their shape and size even under stress and varying environmental conditions, which is crucial for precision components.

Applications of Phenolic Materials

The diverse properties of phenolic materials make them suitable for a wide range of applications across various industries:

Automotive Industry: Phenolic resins are used in the production of brake pads, clutch discs, and other high-temperature automotive components. Their thermal stability and mechanical strength are essential for the durability and performance of these parts.

Electrical and Electronics: Phenolics are widely used in the electronics industry for manufacturing circuit boards, electrical insulators, and other components that require excellent electrical insulation and thermal resistance.

Construction: In the construction industry, phenolic resins are used in the production of laminates, coatings, and adhesives. Their chemical resistance and mechanical strength make them ideal for use in harsh environments.

Aerospace: Phenolic materials are used in the aerospace industry for producing lightweight, high-strength components that can withstand extreme temperatures and mechanical stress.

Consumer Goods: Phenolic resins are also used in the production of various consumer goods, including kitchenware, handles, and appliance housings, where durability and heat resistance are essential.

Market Trends and Growth Drivers

The global phenolic resin market has witnessed steady growth in recent years, driven by increasing demand from the automotive, construction, and electronics industries. Key trends influencing the market include:

Sustainability Concerns: With growing environmental awareness, there is a shift towards the development of eco-friendly phenolic resins. Manufacturers are focusing on producing resins with lower formaldehyde emissions and incorporating renewable raw materials into the production process.

Technological Advancements: Advances in manufacturing technologies are enabling the production of phenolic resins with enhanced properties, such as improved thermal stability and chemical resistance. These advancements are opening up new application areas for phenolic materials.

Increasing Demand for Lightweight Materials: The automotive and aerospace industries are increasingly adopting lightweight materials to improve fuel efficiency and reduce emissions. Phenolic resins, with their high strength-to-weight ratio, are gaining traction as an alternative to traditional materials like metal.

Regional Market Growth: Emerging economies in Asia-Pacific, particularly China and India, are witnessing rapid industrialization and urbanization, driving demand for phenolic resins in construction, automotive, and electronics sectors.

Challenges in the Phenolic Resin Market

Despite the positive growth outlook, the phenolic resin market faces several challenges:

Environmental Regulations: The production of phenolic resins involves the use of formaldehyde, a hazardous chemical. Stringent environmental regulations related to formaldehyde emissions and disposal are posing challenges to manu

tags:

1250kVA oil immersed transformer price

1600kVA oil immersed transformer

FR4 Machined Parts

1250kVA oil immersed transformer

Filament Wound Epoxy Tube

- more+releated article

- 2026-02-281250kVA Oil-Immersed Transformer Price and Cos

- 2026-02-27Detailed Explanation of FR4 Machined Parts Mac

- 2026-02-27Custom 1600kVA Oil Immersed Transformer Manufa

- 2026-02-26Precision FR4 Machined Parts for Electrical In

- 2026-02-26High-Quality Industrial 1250kVA Oil-Immersed T

- 2026-02-25Why is Filament Wound Epoxy Tube More Expensiv

- 2026-02-25XUJUE ELECTRICAL Officially Resumes Operations

- 2026-02-25Solar Duty Transformer: Sizing Challenges, Inv

- 2026-02-11Ztelecgroup Annual Gala Successfully Held

- 2026-02-10G10 epoxy board in the insulation parts of ele