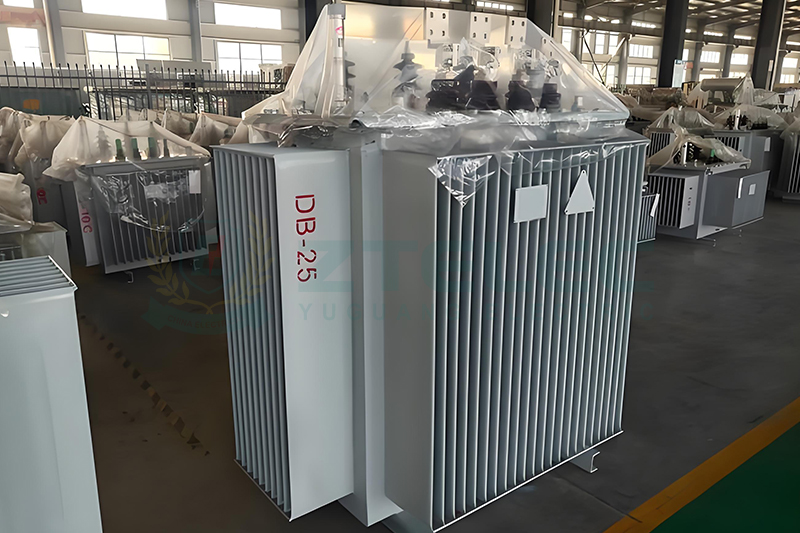

10kV Transformer Replacement Timeline: Installation, Testing, and Commissioning

Replacing 10kV transformers is critical to ensuring reliable and secure power supply. Transformers should be replaced promptly when equipment ages, failures increase, or technical upgrades are necessary. This guide explains the main stages of 10kV transformer replacement, detailing installation, testing, and commissioning timelines and key influencing factors.

Preparatory Work for 10kV Transformer Replacement

Before replacement, assess the old transformer and prepare the new equipment. Select suitable transformers based on specifications, site conditions, and installation environment. Conduct site cleanup and inspect infrastructure to prevent delays.

Preparatory work time: Typically 1-3 days, depending on site complexity.

10kV Transformer Installation

Installation is the core step. Technicians must place the transformer accurately, connect cables, pipes, and cooling systems, and ensure technical parameters like levelness and verticality meet standards.

Installation time: Typically 2-5 days, depending on transformer specifications and site conditions.

10kV Transformer Testing Phase

1. Routine Tests

Insulation Resistance Test: Checks insulation between windings and ground, and among phase windings.

Turning Ratio and Polarity Test: Verifies voltage transformation accuracy.

DC Resistance Measurement: Ensures resistance balance of each phase winding.

Dielectric Loss Factor Test: Assesses insulation material condition.

2. Specialized Tests

Power Frequency Withstand Voltage Test: Verifies main insulation strength.

Partial Discharge Test: Detects internal defects.

Oil Chromatography Analysis: Monitors characteristic gases in oil-immersed transformers.

Testing time: Typically 1-2 days, depending on test complexity.

10kV Transformer Commissioning Phase

1. Protection Device Commissioning

Verify relay protection settings, conduct protection action tests, and check interlocking functions.

2. No-load and Load Tests

No-load closing test: Monitor inrush current, vibration, and noise levels. Load trial operation: Gradually increase load, monitor temperature rise and voltage regulation. Automation integration: Commissioning with SCADA and remote monitoring systems.

3. Formal Commissioning and Handover

Record final operating parameters, conduct operator training, and deliver complete technical documentation.

Commissioning time: Usually 1-2 days. After acceptance, the transformer replacement is complete.

Key Factors Affecting Replacement Time

Transformer Type: Dry-type transformers generally require 0.5-1 day less than oil-immersed transformers.

Site Conditions: Indoor/outdoor installation, space limitations, and weather impact schedules.

Equipment Complexity: On-load tap-changing transformers need longer commissioning.

Team Experience: Skilled teams can reduce project time by 20%-30%.

Parallel Operation: Simultaneous testing and commissioning shorten total time.

Time Optimization Recommendations

Complete foundation construction and pre-assemble components in advance. Select modular transformers to reduce on-site work. Use vacuum oil filters and automated testing instruments to improve efficiency. Apply BIM technology to simulate installation and prevent rework.

The total 10kV transformer replacement time typically ranges from 7-12 days, including preparation, installation, testing, and commissioning. Efficient planning, skilled teams, and proper equipment selection are essential for smooth project execution.

- more+releated article

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri

- 2025-12-24Dry-Type vs. Oil-Immersed Transformer: Is a 20

- 2025-12-22Do you know how to distinguish between good an

- 2025-12-22Why 66kV Power Transformers Are Indispensable

- 2025-12-20Composition and Classification of Insulating R

- 2025-12-20What Are the Key Factors Affecting the Perform

- 2025-12-20Upgrading Manufacturing Processes Enhances the