A Comprehensive Guide to Phenolic Panels: Applications, Benefits, and Key Considerations

2024-08-30 17:11 | By: ZTELEC-www.ztelecgroup.com | 168click

Phenolic panels have become a go-to material across various industries, praised for their durability, versatility, and aesthetic appeal. Whether you're in construction, interior design, or seeking a high-performance material for specialized applications, understanding the features and benefits of phenolic panels can help you make an informed decision. In this article, we’ll delve into everything you need to know about phenolic panels, from their composition to their wide-ranging applications.

1.What Are Phenolic Panels?

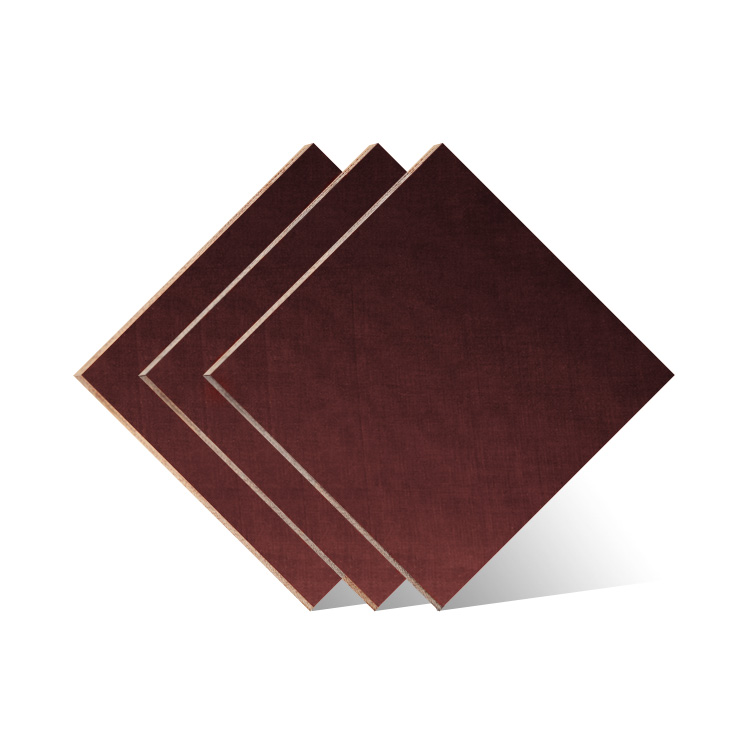

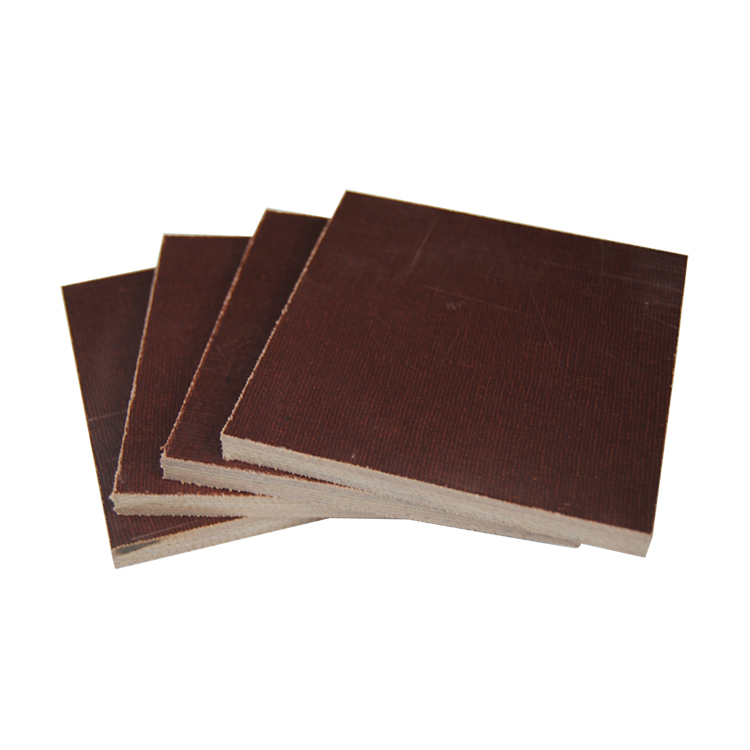

Phenolic panels, also known as high-pressure laminate (HPL) panels, are composite materials made by compressing layers of paper or fabric impregnated with phenolic resin under high pressure and temperature. This process creates a highly durable, dense, and solid panel with a decorative surface layer that can mimic various textures and finishes, such as wood, stone, or metal.

2.Key Features of Phenolic Panels

Durability and Strength:

Phenolic panels are known for their exceptional strength and durability. They can withstand heavy impacts, making them ideal for high-traffic areas or environments where durability is crucial.

Resistance to Moisture and Chemicals:

The non-porous surface of phenolic panels makes them highly resistant to moisture, chemicals, and even UV rays. This resistance makes them suitable for both indoor and outdoor applications, including harsh environments like laboratories and industrial spaces.

Fire Resistance:

Phenolic panels are fire-resistant, complying with various safety standards. They do not emit toxic fumes when exposed to high temperatures, adding an extra layer of safety in residential and commercial buildings.

Low Maintenance:

These panels are easy to clean and maintain, thanks to their smooth, non-porous surface that resists stains and graffiti. A simple wipe-down with mild cleaning agents is often enough to keep them looking new.

Aesthetic Versatility:

Available in a wide range of colors, finishes, and textures, phenolic panels offer design flexibility. Whether you want a sleek, modern look or a natural, rustic feel, there’s a phenolic panel to suit your aesthetic needs.

Applications of Phenolic Panels

Exterior Cladding:

Phenolic panels are widely used in building exteriors due to their weather resistance and aesthetic appeal. They provide a modern, durable facade that protects buildings from environmental factors.

Interior Wall Cladding:

In interiors, phenolic panels are popular for wall cladding in commercial spaces, hospitals, and educational institutions. Their easy-to-clean nature makes them ideal for areas requiring high hygiene standards.

Laboratory Worktops:

Phenolic panels' resistance to chemicals and moisture makes them an excellent choice for laboratory countertops and workstations, where durability and cleanliness are paramount.

Furniture and Partitions:

The material's versatility extends to furniture and partitions, where it is used to create durable, aesthetically pleasing surfaces that can withstand daily wear and tear.

Restroom Partitions:

In public restrooms, phenolic panels are often used for partitions and cubicles due to their resistance to moisture, bacteria, and vandalism.

Benefits of Using Phenolic Panels

Longevity:

Investing in phenolic panels means choosing a material that will last for years, reducing the need for frequent replacements and repairs.

Environmental Sustainability:

Many phenolic panels are made from sustainably sourced materials and can be recycled at the end of their life cycle, contributing to environmental conservation efforts.

Cost-Effectiveness:

While the initial cost of phenolic panels may be higher than some other materials, their durability, low maintenance, and long lifespan make them a cost-effective choice in the long run.

Health and Safety:

The non-toxic nature of phenolic panels, combined with their resistance to bacteria and mold, makes them a safe choice for environments where health and hygiene are priorities.

Key Considerations When Choosing Phenolic Panels

Thickness and Size:

Depending on the application, phenolic panels come in various thicknesses and sizes. Ensure you select the right specifications to meet the structural and aesthetic requirements of your project.

Installation:

Proper installation is crucial for maximizing the benefits of phenolic panels. It's advisable to work with experienced professionals who understand the nuances of this material.

Budget:

While phenolic panels offer excellent value for money, it's essential to balance your budget with the desired quality and longevity.

Supplier Reputation:

Choose a reputable supplier known for high-quality phenolic panels and excellent customer service. This will ensure you get the best product for your needs.

tags:Price of a 1600kVA 10kV Cast Resin Dry-Type Transformer35kV dry-type transformer protection10kV oil-immersed transformer110 kV oil-immersed transformerOil-Immersed Transformer Maintenance

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen