Epoxy FR4 Yellow Laminate vs Pressboard: Choosing the Right Transformer Insulation

In the overall design system of transformers, the choice of insulation materials is a critical factor. Their performance directly determines the operational efficiency, safety and reliability, manufacturing cost, and service life of the transformer. Among the most widely used insulation materials today, epoxy FR4 laminated sheets and pressboard differ significantly in their technical attributes, making them suitable for distinctly different transformer applications.

Material Nature and Core Characteristics

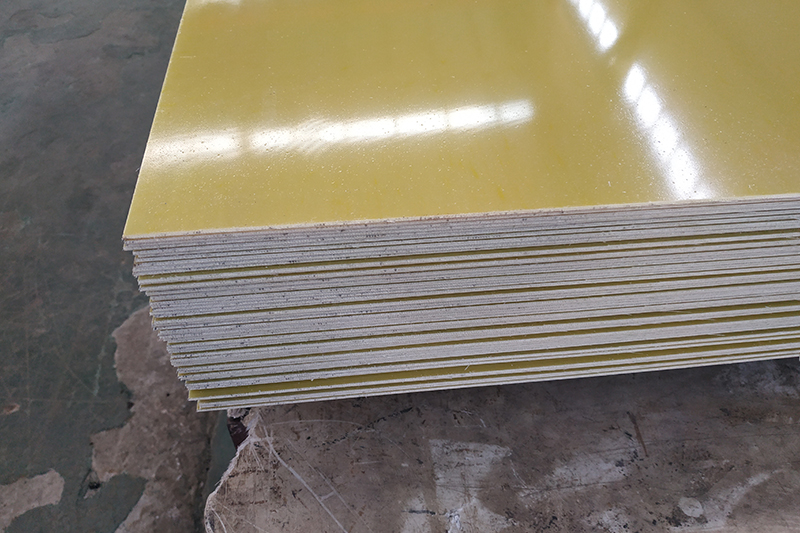

1.Epoxy FR4 Yellow Laminated Sheet

This material uses glass fiber cloth as the reinforcing substrate, impregnated with epoxy resin, and cured under high temperature and high pressure to form a composite sheet structure. Its unique composition gives it the following key characteristics:

· High Structural Strength: Provides excellent mechanical strength and rigidity, serving as a structural framework inside transformers to support windings and the magnetic core.

· Superior Electrical Insulation Performance: Possesses very high dielectric strength, effectively resisting breakdown under high-voltage conditions to ensure electrical safety.

· Excellent High-Temperature Resistance: Typically meets F-class (155°C) or H-class (180°C) insulation standards, maintaining stable performance under elevated operating temperatures.

· Outstanding Environmental Stability: Features very low water absorption, along with excellent moisture and mold resistance, ensuring stable performance even in harsh environments.

· Reliable Flame Retardancy: Achieves UL94 V-0 flammability rating, capable of self-extinguishing when exposed to fire, significantly enhancing transformer safety.

· High-Precision Machinability: Compatible with CNC precision processing, enabling the production of complex-shaped insulation parts with strict dimensional tolerances.

2. Pressboard

Pressboard is a cellulose-based material made from wood pulp or cotton pulp, processed with special techniques to achieve electrical insulation functionality. Its core characteristics include:

· Good Flexibility and Compressibility: Exhibits excellent toughness and elasticity, making it convenient for winding and folding operations while effectively filling gaps inside transformers.

· High Oil Absorption Performance: One of its most critical features. Pressboard can quickly and thoroughly absorb transformer oil, forming an “oil–paper” composite insulation system. Once impregnated, its dielectric strength is significantly enhanced.

· High Cost-Effectiveness: Both raw material and processing costs are relatively low, providing clear economic advantages.

· Environmentally Friendly: Made from natural plant fibers, it is biodegradable after disposal and has minimal environmental impact.

· Limited Thermal Performance: Generally only meets Class A (105°C) or Class E (120°C) insulation requirements. In oil-immersed environments, its actual working temperature limit is determined by the properties of the transformer oil.

Performance Differences and Application Scenarios

The choice between the two materials mainly depends on the type and operating principle of the transformer.

1.Scenarios Favoring Epoxy FR4:

Dry-Type Transformers: This is the core application field for epoxy FR4. Since dry-type transformers lack transformer oil for cooling and insulation, the insulation material must meet strict requirements in terms of thermal resistance, dielectric strength, moisture resistance, and flame retardancy. Epoxy FR4 is commonly used for coil skeletons, insulation barriers, and baffles.

High-Frequency Switching Power Transformers: These transformers operate at higher frequencies, requiring insulation materials with low dielectric loss and stable performance. Epoxy FR4 provides superior electrical properties under high-frequency conditions compared to most alternatives, and its high mechanical strength supports transformer miniaturization and high power density design.

Harsh Environmental Applications: In high-humidity or heavily polluted environments, epoxy FR4’s excellent environmental stability ensures reliable transformer operation.

2. Scenarios Favoring the Use of Pressboard

Oil-Immersed Power Transformers: This is the traditional application field where insulation pressboard excels. Whether for large power transformers or small oil-immersed transformers, pressboard remains the preferred insulation material. The main reasons for choosing pressboard are:

—After absorbing transformer oil, the insulation performance of pressboard far exceeds that in its dry state. This oil–paper composite system has been proven through long-term practice to offer extremely high reliability.

—During transformer assembly, paper-based insulation components can be compressed and adjusted to ensure tight contact between windings and the core, effectively reducing vibration and noise during operation.

—Once impregnated with transformer oil, micro-circulation of the oil can occur within the pressboard, helping to dissipate heat and ensuring stable transformer operation.

—For large oil-immersed transformers, using epoxy FR4 as the insulation material would significantly increase costs, while pressboard can meet performance requirements while providing a highly competitive cost advantage.

In practical design, mixed use of both materials is sometimes applied. For instance, in large oil-immersed transformers, epoxy FR4 may be used for certain support components requiring very high mechanical strength, while the main insulation structure still relies on pressboard. Ultimately, material selection must be determined by a comprehensive consideration of specific design specifications, relevant safety standards (such as UL and IEC), and budget constraints, to ensure an optimal balance among performance, safety, and cost-effectiveness.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen