Epoxy FR4 yellow board in power transformer

In power systems, transformers are the core equipment for energy transmission and distribution. The reliability of their internal insulation system directly determines operational safety and service life. As a key insulating material, Epoxy FR4 Yellow Board is widely used in transformer insulation structures due to its excellent comprehensive properties. Below, we analyze it from the perspectives of definition, characteristics & advantages, and applications.

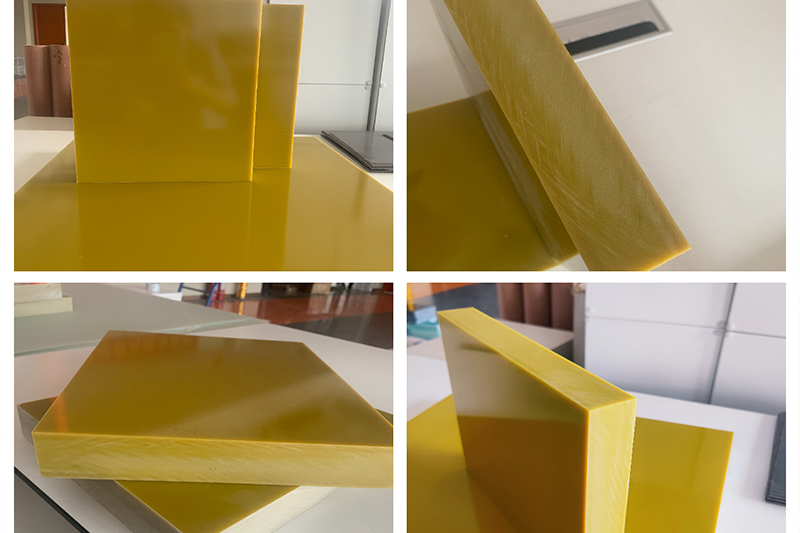

Definition of Epoxy FR4 Yellow Board

Essentially, Epoxy FR4 Yellow Board is an epoxy glass cloth laminated sheet. Its name can be broken down as follows:

Epoxy: Refers to the use of epoxy resin, which provides outstanding electrical properties, strong adhesion, and excellent mechanical strength, forming the performance foundation of the board.

FR4: A grade designation. “FR” stands for Flame Retardant, while “4” originally referred to a specific glass cloth weave and resin formulation. Today, FR4 is a general term for this class of epoxy glass cloth laminates.

In simple terms, Epoxy FR4 Yellow Board is manufactured by impregnating electronic-grade fiberglass cloth with epoxy resin, followed by hot pressing under high temperature and pressure to form a rigid laminated sheet.

Key Properties and Advantages of Epoxy FR4 Yellow Board

Epoxy FR4 Yellow Board has become a preferred transformer insulation material because of its outstanding properties across multiple dimensions:

1.Excellent Electrical Insulation

High dielectric strength: Withstands very high voltages without breakdown, effectively isolating windings and core components at different potentials.

High insulation resistance: Maintains high resistance even in hot and humid environments, minimizing leakage current.

Low dielectric loss: Reduces energy loss and heat generation under high voltage or high-frequency fields, improving transformer efficiency.

2.Superior Mechanical Strength

High rigidity and strength: Provides strong support for windings, withstanding electromagnetic forces from short-circuit currents and preventing deformation.

Good machinability: Supports CNC machining, drilling, and milling, making it suitable for manufacturing complex parts such as spacers and end rings.

3.Outstanding Thermal Resistance

Thermal class typically F or higher, ensuring long-term stability in high-temperature transformer environments.

4.Reliable Flame Retardancy (FR)

Meets UL94 V-0 standard, self-extinguishes upon ignition, and prevents fire propagation in transformers.

5.Chemical Resistance and Moisture Protection

Resistant to transformer oil, acids, and alkalis; low water absorption ensures stable performance in humid conditions and extends service life.

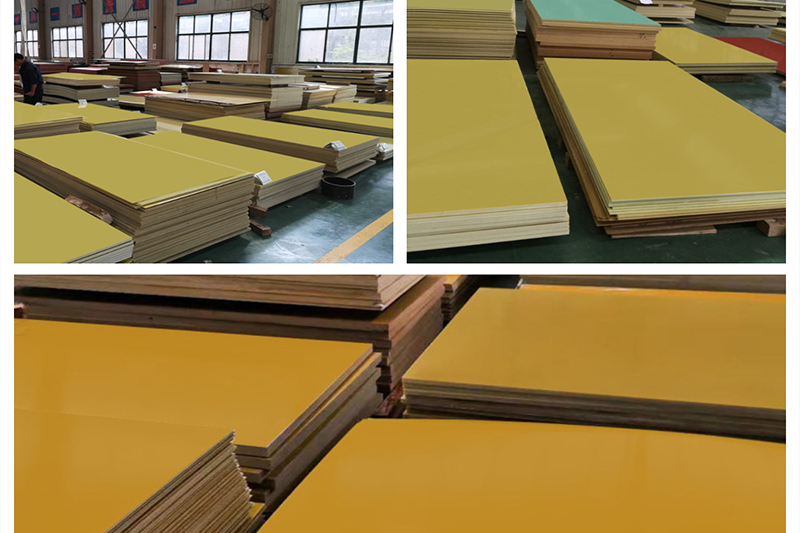

Applications of Epoxy FR4 Yellow Board in Power Transformers

Epoxy FR4 Yellow Board mainly serves as both primary insulation and structural support within transformers. Typical applications include:

1.Insulating spacers: Placed between windings and core or between windings and press plates, providing both insulation and mechanical support.

2.End rings/end insulation: Mounted at coil ends to reinforce insulation, provide clamping force, and improve coil stability.

3.Sticks (spacers for cooling channels): Inserted inside windings to form vertical oil ducts for enhanced cooling, while offering radial mechanical support.

4.Clamping insulation: Positioned between clamping components and windings to ensure ground insulation and prevent faults.

5.Barrier boards: Installed between windings as main insulation barriers, preventing inter-winding dielectric breakdown.

Through these roles, Epoxy FR4 Yellow Board forms a robust and reliable insulation framework for transformers, safeguarding equipment against electrical and mechanical stress.

With its exceptional electrical insulation, high mechanical strength, excellent thermal and flame resistance, and stable chemical and moisture-proof properties, Epoxy FR4 Yellow Board has become an indispensable material in transformer insulation systems. It not only provides reliable insulation and structural support inside transformers but also ensures the long-term safe, efficient, and stable operation of power equipment.

As performance and reliability requirements in the power industry continue to rise, Epoxy FR4 Yellow Board will remain a critical material, offering strong assurance for grid stability and secure energy transmission.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen