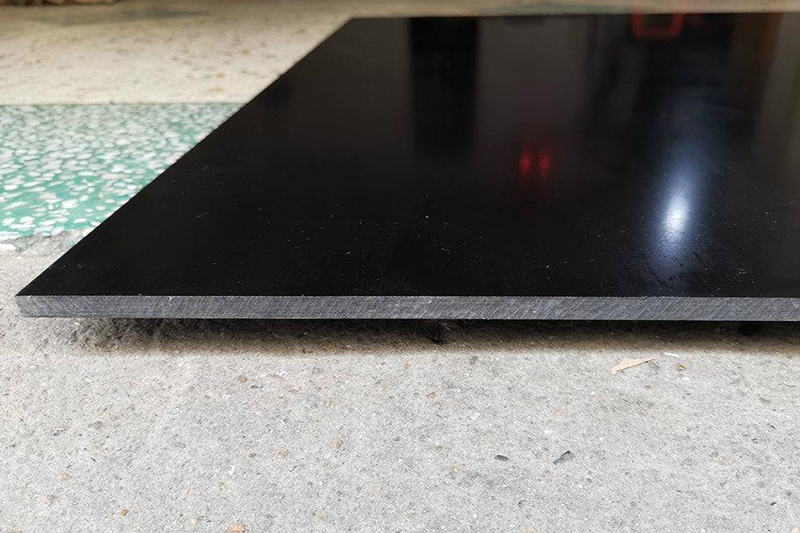

Black FR4 Anti-Static Fiberglass Board for PCBs

In the field of electronic manufacturing, PCB (printed circuit board) is the core carrier of electronic components, and its performance is directly related to the reliability and stability of electronic products. As a high-performance PCB substrate, black FR4 anti-static board occupies an important position in high-precision fields such as semiconductors, communications, and precision instruments with its unique anti-static properties, excellent mechanical properties, and excellent electrical properties. This article will comprehensively explain the characteristics, application scenarios, and selection points of black FR4 anti-static board.

Basic characteristics of black FR4 anti-static board

1. Core material

The black FR4 anti-static fiberglass board uses FR4 epoxy glass fiber cloth as the substrate, and achieves a black appearance by adding black solder mask ink or dye. This black characteristic makes it popular in high-end equipment or scenarios with high requirements for concealment, which can not only meet functional requirements, but also take into account the professionalism and confidentiality of the appearance.

2.Key performance

Anti-static performance: The surface resistance of the black FR4 anti-static board is stably maintained in the range of 10⁶~10⁹Ω, which can effectively prevent the accumulation of static electricity and avoid the potential damage of static electricity to electronic components from the root.

Mechanical properties: The black FR4 anti-static board has high rigidity and can withstand large external forces without deformation. It also has excellent high temperature resistance and can adapt to the high temperature environment in the electronic manufacturing process. At the same time, it has strong chemical corrosion resistance and can resist the erosion of various chemical substances.

Electrical performance: The dielectric constant of the black FR4 anti-static board is stable. It performs well in high-frequency circuits and can reduce the loss and interference during signal transmission.

3. Anti-static implementation method

Surface treatment: Manufacturers achieve anti-static effects by applying anti-static coatings (such as carbon powder or conductive polymers), but this method may reduce durability due to wear and tear during long-term use, affecting the sustainability of anti-static performance.

Material modification: Technicians incorporate conductive fillers (such as carbon fiber) into FR4 resin to evenly distribute the body resistance, thereby achieving a more lasting anti-static effect.

Structural design: Engineers embed a grounding layer in the multi-layer board structure and use the grounding layer to guide the release of static electricity, which can further enhance the anti-static ability and ensure that static electricity can be discharged in a timely and safe manner.

Application scenarios of black FR4 anti-static fiberglass board

1. Semiconductor manufacturing and testing

In semiconductor production links such as wafer manufacturing and chip packaging, static discharge is likely to cause the performance of components to deteriorate or even be directly scrapped. With its excellent anti-static performance, black FR4 anti-static board is widely used in semiconductor test fixtures, wafer process fixtures, PCB test racks and other equipment to ensure the electrostatic safety of the production process.

2. Communication equipment and precision instruments

5G base stations, optical fiber communication equipment, etc. have extremely high requirements for the stability of signal transmission. Black FR4 anti-static board can improve the signal quality of communication equipment by reducing dielectric loss and signal distortion. At the same time, its high mechanical strength can support high-density wiring and meet the design requirements of equipment miniaturization and lightweight.

3. Electronic assembly and automation equipment

In electronic assembly processes such as SMT patch and wave soldering, static electricity may cause components to absorb dust and poor welding. Black FR4 anti-static board can be used to make components such as carriers and trays for automation equipment, effectively eliminating electrostatic interference and improving production yield.

4. Transformer and motor insulation

The black FR4 anti-static board has both insulation and anti-static functions, and can be used for transformer insulation partitions, motor insulation pads and other components. It can isolate the electrical circuit while preventing static electricity from damaging the precision components inside the transformer and motor, ensuring the stable operation of the equipment.

Key points for selecting black FR4 anti-static fiberglass board

Black FR4 anti-static board has become the core material in the field of high-precision electronic manufacturing due to its advantages of anti-static, high mechanical strength, and reliable electrical performance. Users need to consider the following factors when selecting:

Anti-static performance: Users need to select products with surface resistance or volume resistance that meet the standards according to the electrostatic sensitivity requirements of specific application scenarios.

Temperature resistance level: Enterprises should combine the temperature range of the use environment to ensure that the selected board can maintain stable performance under high temperature conditions.

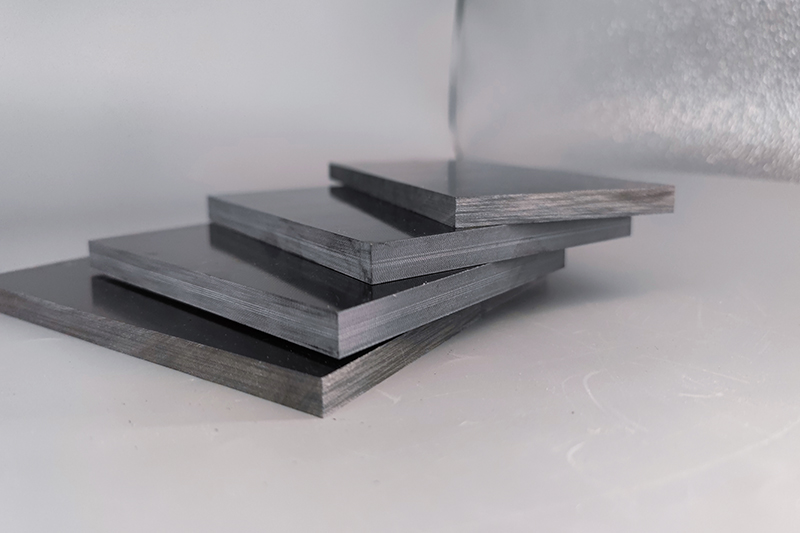

Thickness and size: Purchasing personnel should select appropriate thickness and size based on the design requirements of the actual equipment to ensure the adaptability of the installation and the stability of the structure.

Supplier selection: Users should choose high-quality suppliers that have passed international certifications. Their product quality is more guaranteed and can ensure the long-term stable operation of PCB boards.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen