Analysis of the industrial application of FR4 anti-static fiberglass board

In high-end industrial fields such as electronic manufacturing, new energy vehicles, and aerospace, static control is the key to ensuring product yield and equipment safety. Anti-static FR4 fiberglass board is becoming an indispensable basic material for these industries with its unique combination of properties.

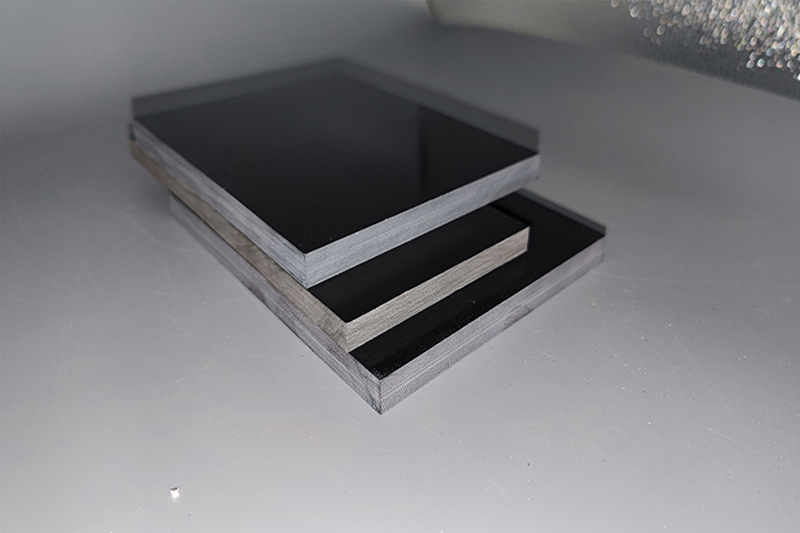

What is FR4 anti-static fiberglass board?

Traditional FR4 board is a composite material made of glass fiber cloth impregnated with epoxy resin, which is widely used as a substrate for circuit boards. On this basis, anti-static FR4 board achieves anti-static function in two ways:

Internal doping: The manufacturer adds conductive carbon black, carbon nanotubes and other fillers to the resin to form a conductive network.

Surface treatment: Processing personnel construct a dissipative layer by nickel plating, coating with conductive coating, etc.

This transformation enables the board to quickly conduct static electricity and avoid the risk of short circuit.

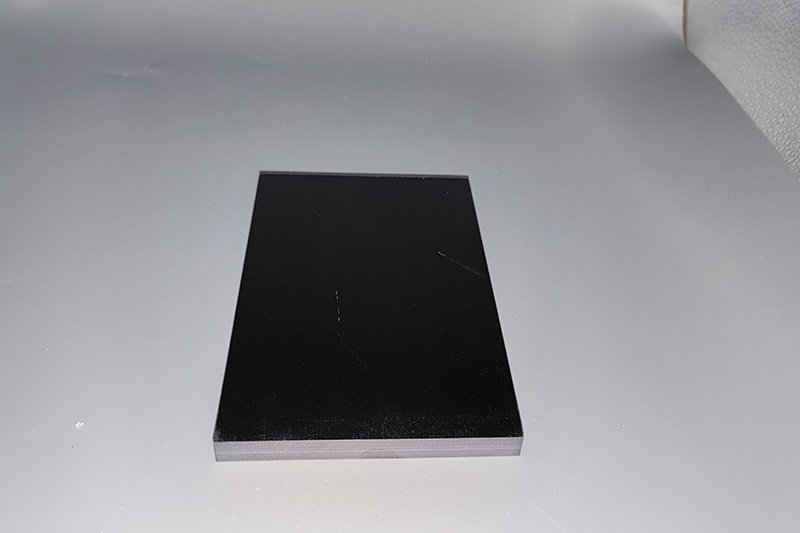

Core characteristics of FR4 anti-static fiberglass board

Surface resistance: FR4 anti-static fiberglass board is between insulator and conductor, which can slowly release static electricity and avoid charge accumulation.

Mechanical strength: FR4 anti-static fiberglass board retains the high rigidity, impact resistance and dimensional stability of FR4.

Environmental stability: FR4 anti-static fiberglass board is resistant to high temperature and chemical corrosion, and is suitable for harsh industrial environments.

Typical industrial application scenarios of FR4 anti-static boards

1. Electronic manufacturing and semiconductor fields

In terms of PCB substrates, companies use anti-static FR4 fiberglass boards for precision circuit boards such as high-frequency communication equipment and medical instruments to prevent static electricity from breaking down sensitive components such as IC chips.

In terms of semiconductor carriers, relevant manufacturers make anti-static FR4 fiberglass boards into wafer trays and test fixtures to prevent static electricity from adsorbing dust or damaging wafers.

2. Industrial automation field

On robot control boards, automation equipment manufacturers use anti-static FR4 fiberglass boards to reduce signal misoperation caused by static electricity in dusty and oily environments.

In terms of sensor substrates, such as humidity sensors, manufacturers use anti-static FR4 fiberglass boards to improve their long-term stability.

3. Energy and power fields

In new energy equipment, energy companies use anti-static FR4 fiberglass boards for insulating components of photovoltaic inverters and wind power control cabinets to prevent static electricity accumulation from causing arcs.

In terms of high-voltage insulation boards, the power sector uses anti-static FR4 boards that have both insulation and static dissipation requirements in substation equipment.

4. Medical equipment field

In imaging diagnostic equipment, medical equipment manufacturers use anti-static FR4 sheets for circuit support boards of MRI and CT scanners to prevent static electricity from interfering with imaging accuracy.

In surgical instrument housings, relevant manufacturers use FR4 sheets with anti-static coatings for electrosurgical equipment.

Key parameters for selecting FR4 fiberglass anti-static board

Resistance range: Companies choose surface resistance according to the application, for example semiconductors and flammable environments have different requirements.

Dielectric constant (Dk) and loss factor (Df): High-frequency applications require low Dk/Df values.

Thickness tolerance: Precision circuits have strict requirements.

Compliance with standards: Such as UL94 V0 flame retardant, IPC-4101E board specifications.

Anti-static FR4 fiberglass board plays an irreplaceable role in many high-end industrial fields with its excellent anti-static performance, reliable mechanical and environmental stability. With the continuous improvement of product precision and safety requirements in various industries, the application prospects of anti-static FR4 fiberglass board will be broader, and its technology will continue to be optimized in continuous practice to ensure the safety and efficiency of industrial production.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen