The key role of 3240 fiberglass sheet in power equipment, how to choose it correctly?

In the safe and stable operation of power equipment, the performance of insulation and structural materials plays a fundamental supporting role. As a composite material that integrates electrical insulation, mechanical strength, temperature resistance and corrosion resistance, 3240 fiberglass sheet has become an indispensable key component in the power field. From transformers, distribution boxes to insulating structural parts of various electrical equipment, their performance directly affects the reliability and service life of the equipment. This article will deeply analyze the core role of 3240 fiberglass sheet in power equipment and how to select 3240 fiberglass sheet.

The key role of 3240 fiberglass sheet in power equipment

3240 fiberglass sheet plays a vital role in electrical equipment, and its multiple functions ensure the normal operation and safety of electrical equipment.

1. Electrical insulation

The primary function of 3240 insulation board is to provide electrical insulation. In electrical equipment, isolation between different potentials is essential to prevent dangerous situations such as current leakage, short circuit and arc discharge. 3240 fiberglass sheet has excellent insulation performance and can withstand high voltage without breakdown, thereby effectively isolating components with different potentials and ensuring the electrical safety of electrical equipment.

2. Heat dissipation and thermal isolation

During the operation of electrical equipment, a certain amount of heat will be generated. If the heat cannot be dissipated in time, it may cause the equipment to overheat, which in turn affects its performance and life. 3240 fiberglass sheet has a certain thermal conductivity, which can help the equipment dissipate heat and reduce the temperature. At the same time, in some cases, it can also play a role in thermal isolation, preventing heat from being transferred from one component to another, thereby maintaining the thermal stability of the equipment.

3. Mechanical support and protection

In addition to electrical insulation, 3240 fiber sheet also plays a role in mechanical support and protection. In electrical equipment, many components require a stable support structure to maintain their position and function. 3240 fiber sheet has high mechanical strength and can withstand certain pressure and load, so it is often used as a supporting component, such as circuit board support, coil skeleton, etc. At the same time, it can also protect the surrounding electrical components from physical damage, such as impact, vibration, etc.

4. Moisture and corrosion resistance

When electrical equipment is running in a humid environment, it may be affected by corrosive substances such as moisture and salt spray, resulting in performance degradation or even damage. 3240 fiberglass sheet has good moisture and corrosion resistance, which can effectively block the intrusion of moisture and corrosive substances, thereby protecting electrical equipment from damage.

How to choose 3240 fiberglass board correctly?

When choosing 3240 fiberglass board, its application scenario, material properties, size specifications and quality standards need to be considered comprehensively.

Identify the application scenario

3240 epoxy fiberglass board is widely used in electrical equipment, such as transformer oil environment, distribution box, mold splint, etc., as an insulating structural component.

Confirm whether its temperature resistance grade (Grade B, 130℃) meets your application scenario requirements.

Understand the material properties

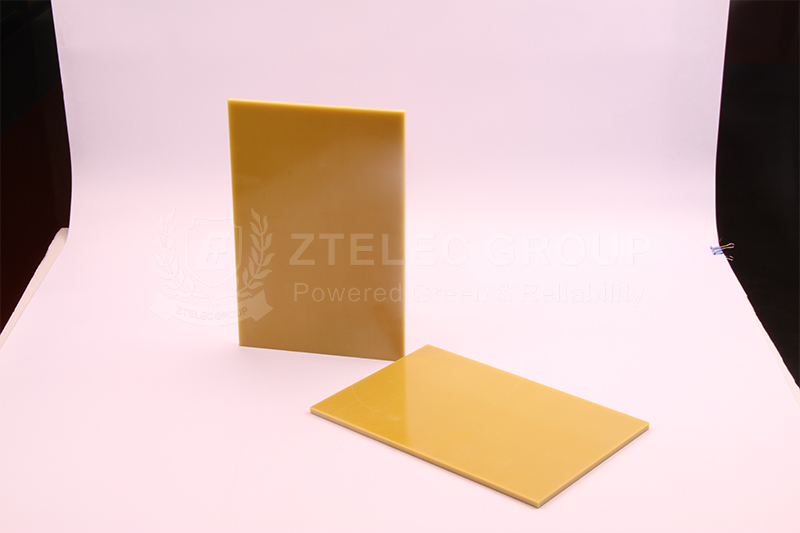

3240 fiberglass board is made of glass fiber cloth and epoxy resin, and has excellent electrical insulation, mechanical strength and chemical corrosion resistance. Its common colors include yellow, aqua and black. Its temperature resistance grade ensures that it can maintain stable performance in high temperature environment.

Determine the size and thickness

The standard size of 3240 epoxy fiberglass board is usually 1020mm×2020mm, with a thickness range of 0.5mm to 50mm.

Choose the appropriate size and thickness according to the actual installation space and insulation requirements.

Consider processing convenience

3240 fiberglass sheet is easy to cut and drill, suitable for making various insulation accessories and equipment structural parts. If complex processing is required, please ensure that the processing equipment is compatible and the accuracy meets the standards.

Choose a reliable manufacturer

Give priority to products from well-known manufacturers to ensure reliable quality. Regular manufacturers usually implement strict quality inspection processes, and product performance is more stable.

Refer to relevant standards

When selecting, you can refer to national or industry standards to ensure that the product meets the specification requirements.

3240 fiberglass sheet plays an irreplaceable role in power equipment with its diverse functions, and correct selection is the key to fully exerting its performance. By mastering these key points, you can find the appropriate 3240 fiberglass sheet for power equipment to ensure stable operation of the equipment.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri