Dry-Type Transformer Operation Failures: Causes and Diagnostic Methods

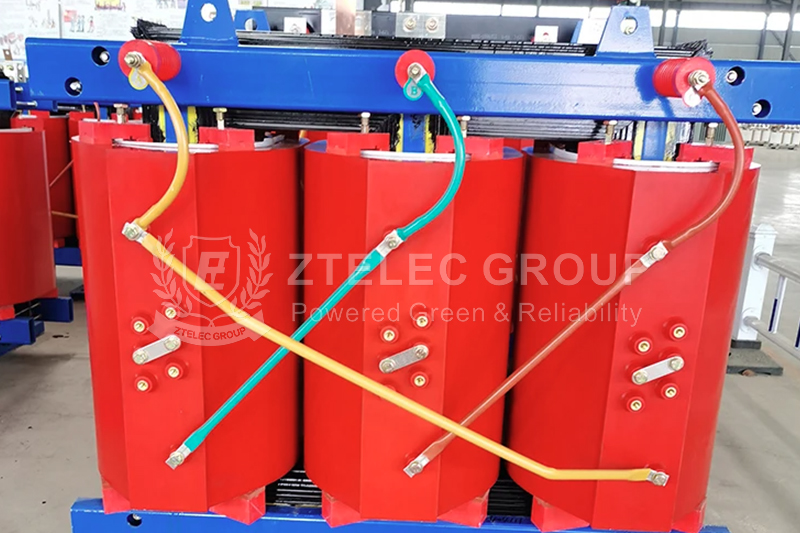

Dry-type transformers are essential in modern industrial, commercial, and civil power systems due to their fire resistance, explosion protection, and maintenance-free operation. Despite these advantages, various failures can still occur after prolonged operation. This article analyzes common failure types in dry-type transformers and introduces diagnostic techniques to support safe and stable transformer performance.

Common Dry-Type Transformer Failure Types and Causes

Abnormal Temperature Rise

Temperature anomalies are one of the most obvious signs of operational failure in dry-type transformers. When a temperature increase is detected, the thermostat, thermometer, and blower should be inspected first. If these devices function normally, the fault is likely internal.

Winding short circuit: Localized heat rise may occur due to short circuits between winding layers or turns. DC resistance and ratio tests can confirm this fault.

Core failure: Causes include core short circuits, damaged insulation screws, or insufficient clamping. No-load and insulation resistance tests are effective for diagnosis.

Overload operation: Prolonged or sudden overloads lead to rising temperatures. Analyzing load records and temperature trends can help identify this issue.

Poor heat dissipation: Clogged ventilation ducts, fan failures, or high ambient temperatures reduce cooling efficiency. Regular ventilation system maintenance is crucial.

Abnormal Noise

Dry-type transformers emit a consistent electromagnetic hum under normal conditions. Any irregular or abnormal sound requires detailed diagnosis.

Internal causes: Loose core clamps, ungrounded core discharge, poor switch contact, or contaminated bushings can produce abnormal vibrations or discharge sounds.

External causes: Overload, overvoltage, phase loss, grid resonance, low-voltage short circuits, or loose connections may lead to loud or irregular noise patterns.

Decreased Insulation Resistance

Insulation resistance deterioration is often caused by moisture, dust, or material aging, increasing the risk of breakdown. Focused inspections include:

Winding condition: Clean and dry the winding surface when condensation or dust is present.

Core insulation: Damp core insulation can be dried using sun lamps or no-load heating methods.

Insulation material: Aged materials should be replaced promptly and regularly maintained.

Multi-Point Grounding of the Core

When multiple grounding points exist on the transformer core, circulating currents can cause overheating. Both external and internal factors must be considered.

External: Moisture, dust, or metallic dust reduce insulation effectiveness.

Internal: Low-quality silicon steel, improper lamination, or over-compression may cause grounding issues. DC or AC detection methods, capacitor discharge, or return-to-factory inspection may be required.

Diagnostic Methods for Dry-Type Transformer Failures

Visual Inspection and Initial Testing

Appearance: Check for casing deformation, internal foreign objects, and loose fasteners.

Thermostat and fan check: Ensure accurate readings and smooth fan operation.

Insulation resistance: Use a megohmmeter to measure high- and low-voltage side resistance to ground.

Electrical Testing and Data Analysis

DC resistance test: Verify high and low-voltage winding resistance and ensure the three-phase imbalance is within 2%.

Ratio test: Detect short circuits or turn-to-turn faults using a transformer ratio tester.

AC withstand voltage test: Identify dampness, cracking, or winding looseness in main insulation.

No-load test: Analyze core conditions such as aging or multiple ground points based on no-load loss.

Fault Localization and Handling

Winding faults: Replace damaged windings and re-perform casting procedures.

Core faults: Bake damp cores and repair insulation or replace silicon steel sheets as needed.

Cooling system issues: Clean ducts, replace fans, and improve the installation environment.

External connection faults: Tighten loose terminals, repair bushings, and clean surfaces to restore proper function.

Understanding the common operational failures of dry-type transformers and applying systematic diagnostic methods is crucial to maintaining safe and efficient power systems. Regular inspections, accurate testing, and timely interventions can greatly extend the service life and reliability of the transformer.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri