what is phenolic material

2024-07-02 15:52 | By: ZTELEC-www.ztelecgroup.com | 112click

What are phenolic resins?

Phenolic resins, also known as phenol formaldehyde resins (PF) or phenoplasts, are synthetic polymers obtained by the reaction of phenol or substituted phenol with formaldehyde. They were the first commercial synthetic resins and were used as the basis for Bakelite.

Characteristics of phenolic board

Phenolic boards are a type of construction material composed of layers of paper and resin. Here are some of their key characteristics:

Properties:

Heat resistance: Phenolic resins are known for their heat resistance.

Hardness: They are hard materials.

Strength: Phenolic boards are extremely strong. They have a dense core made from layers of paper impregnated with thermosetting resin.

Lightweight: Despite their strength, these boards are lightweight, which makes them an ideal choice for many commercial and residential applications.

Durability: They are durable materials, known for their resistance to wear, weather, and impact.

Fire Resistance: Phenolic boards have good fire-resistance properties due to their non-combustible nature.

Moisture Resistance: They are known for their excellent moisture resistance capabilities, making them highly suitable to be used in humid environments where dampness can cause permanent damage1.

Scratch Resistance: Phenolic boards are highly scratch-proof.

Electrical Insulation: Phenolic materials offer exceptional properties such as electrical insulation.

These characteristics make phenolic boards a popular choice in a variety of modern construction applications, including floors, walls, tables, doors, and furniture. They are also used for countertop surfaces, wall panels, partitions, door cores, and even flooring underlayment in commercial settings. Despite their strength and durability, phenolic boards are also easy to clean and maintain

Phenolic Material Manufacturing Explainer Video

What type of plastic does phenolic plastic belong to?

Phenolic plastic, also known as phenol formaldehyde resin, belongs to the category of thermosetting plastics. It is a composite resin material made from a combination of phenol and aldehyde.

Here are some key characteristics of phenolic plastic:

Rigidity: Phenolic plastic is a rigid material.

Heat Resistance: It was created to tolerate high temperatures.

Electrical Insulation: It was designed to better manage electric power than other plastics.

Variety of Uses: It is used in a wide range of consumer fitting applications.

The properties of phenolic plastic can vary depending on the type of aldehyde used, although formaldehyde is most common. To transform the aldehyde and phenol mixture into a phenolic sheet, paper, glass, or cloth is impregnated with the synthetic mixture, then layered and pressed together using heat and pressure. As a result of the heat and pressure, polymerization occurs and the resin reacts with the paper, cloth, or glass to produce a hard, dense sheet of phenolic plastic.

Types of phenolic material

Phenolic materials, also known as phenolic plastics, are composite materials produced by applying heat and pressure to paper or fabric imbued with synthetic resin. They come in various forms and types, each offering unique properties and benefits. Here are some of the types of phenolic materials:

Paper-based Phenolic Composites: These are made from paper and phenolic resin. They are often used in electrical insulation and circuit boards.

Cloth-based Phenolic Composites: These are made from cloth (like cotton or linen) and phenolic resin. They are often used in applications that require low friction, such as loaded bearings.

Glass-based Phenolic Composites: These are made from glass fibers and phenolic resin. They are often used in applications that require high strength and rigidity.

Novolacs and Resols: These are the two primary types of phenolic materials, distinguished by their aldehyde to phenol ratios. Novolacs have a linear or slightly branched chemical structure, while resols feature a cross-linked, three-dimensional structure.

Phenolic Foam: This is a type of phenolic material that is typically used in insulation applications.

Paper-reinforced Phenolic: This type of phenolic material is reinforced with paper.

Canvas and Linen Phenolics: These phenolic materials are reinforced with canvas or linen.

Nylon-reinforced Phenolic (N-1): This type of phenolic material is reinforced with nylon.

Glass-reinforced Phenolic (G-3): This type of phenolic material is reinforced with glass.

Each type of phenolic material has its unique properties and uses, making them suitable for a wide range of applications in various industries

Advantages and disadvantages of phenolic panels

Phenolic panels, made from phenolic resins, are widely used in various applications due to their unique properties. Here are some of the advantages and disadvantages of phenolic panels:

Advantages:

Durability: Phenolic panels are exceptionally durable and resistant to impact, scratches, moisture, and chemicals. They are built to withstand heavy use and harsh environmental conditions, making them suitable for high-traffic areas.

Design Flexibility: Phenolic panels offer a wide range of aesthetic options. They can be easily shaped, bent, and cut, enabling the creation of unique and intricate designs.

Weather Resistance: Phenolic panels are highly resistant to weathering, UV rays, and moisture1. They do not rot, warp, or corrode, maintaining their appearance and structural integrity even in harsh environmental conditions.

Thermal Insulation: Phenolic panels often have insulating properties, helping in maintaining a comfortable indoor environment1. They contribute to energy efficiency by providing thermal insulation to the buildings they adorn.

Disadvantages:

Cost: Compared to other materials, phenolic boards are relatively expensive.

Limited Aesthetic Options: They have limited aesthetic options compared to more versatile materials like wood or plastic laminates3.

Indoor Air Quality: Phenolic resins can potentially affect indoor air quality.

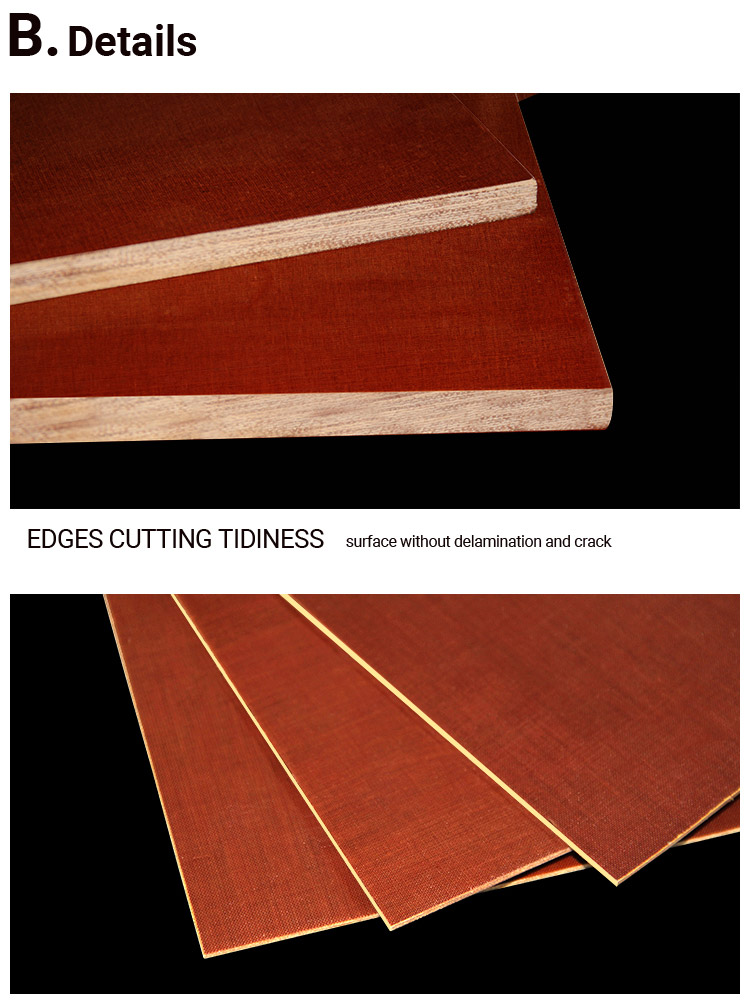

Waste Generation: Indiscriminate cutting by inexperienced workers can lead to unintended waste.

Despite these disadvantages, phenolic panels are still a popular choice in many industries due to their durability, versatility, and resistance to various environmental factors.

Phenolic Board Uses

Phenolic boards, made from phenol resin-impregnated paper, are used in a variety of modern construction applications due to their excellent resistance to moisture, chemicals, mold, fungi, fire, and impact1. Here are some key uses:

Here are some key properties and uses of phenolic resins:

Countertop surfaces: Phenolic boards are often used for countertop surfaces due to their durability and resistance to moisture.

Wall panels and partitions: They can be used to create wall panels and partitions, providing a strong and lightweight solution.

Door cores: Phenolic boards can be used as door cores, offering excellent resistance to impact.

Flooring underlayment: In commercial settings, they can be used as flooring underlayment.

Construction: Phenolic plywood is an increasingly popular material in the construction industry due to its exceptional mechanical properties and weather resistance. It is frequently used for bridge, wall, and roof construction in a wide variety of formwork applications.

Cabinetry: Phenolic board is used to build kitchen and bathroom cabinets.

Molded products: They have been widely used for the production of molded products including billiard balls, laboratory countertops, and as coatings and adhesives.

Circuit boards: They were at one time the primary material used for the production of circuit boards but have been largely replaced with epoxy resins and fiberglass cloth, as with fire-resistant FR-4 circuit board materials.

Insulation in electrical equipment: Phenolic resins were first combined with paper and fabrics to produce Micarta® for use as insulation in electrical equipment.

Knife handles: It has become a popular material for knife handles as it machines readily, polishes well, and has an intrinsic grip when wet.

Friction materials: Their high heat resistance makes them useful as binders in the friction materials of clutch discs and brake pads, as well as in abrasive cut-off wheels.

Lumber industry: A large consumer of phenolic resins is the lumber industry especially in North America where it is used in the manufacturing of OSB, or oriented strand board.

There are two main production methods for phenolic resins. One reacts phenol and formaldehyde directly to produce a thermosetting network polymer, while the other restricts the formaldehyde to produce a prepolymer known as novolac which can be moulded and then cured with the addition of more formaldehyde and heat.Customers who want to buy can contact us ztelecgroup

tags:insulation failure transformertransformer short circuittransformer overheatingtransformer overloadtransformer maintenance

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri