Upgrading Manufacturing Processes Enhances the Reliability and Service Life of 35kV Oil-Immersed Transformers

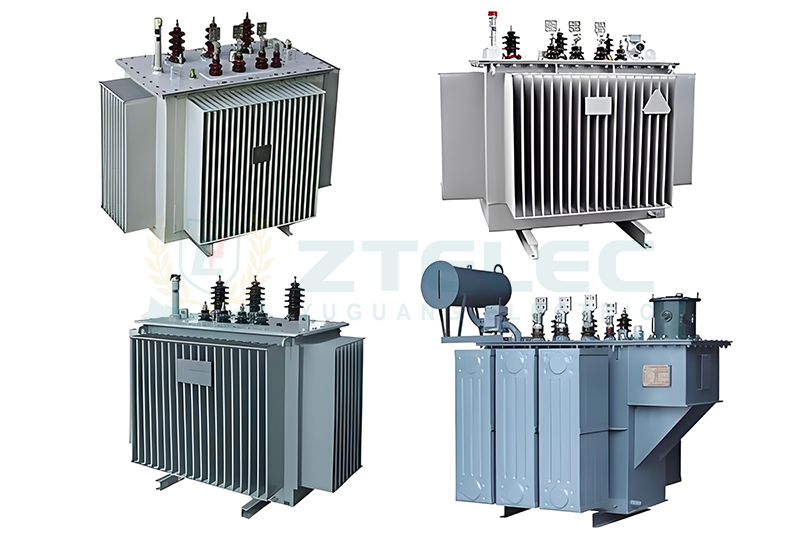

In modern power systems, 35kV oil-immersed transformers are core equipment for electrical energy conversion and distribution. As power grids continue to develop toward intelligence, automation, and higher power quality requirements, end users place increasing demands on transformer reliability, safety, and long-term operational stability. Improving the manufacturing processes of 35kV oil-immersed transformers has therefore become a key competitive advantage for power equipment manufacturers.

This article systematically analyzes how comprehensive upgrades in manufacturing processes can significantly enhance transformer performance, extend service life, and reduce total lifecycle operating costs.

Challenges of Traditional Manufacturing Processes

During long-term operation, transformers produced using traditional manufacturing methods often encounter a range of reliability issues. Insulation materials may age prematurely, resulting in reduced dielectric strength and increased risk of partial discharge. Winding deformation can occur under short-circuit forces, leading to unstable electrical performance. Inadequate sealing structures may cause insulating oil leakage or contamination, while localized overheating accelerates overall aging. In addition, insufficient mechanical strength limits the transformer’s ability to withstand short-circuit impacts.

These problems are largely caused by limited process precision and insufficient quality control during manufacturing, creating hidden risks for long-term stable operation.

Key Directions for Upgrading 35kV Oil-Immersed Transformer Manufacturing

Advanced Core Manufacturing Technology

Modern core manufacturing for 35kV oil-immersed transformers focuses on reducing losses and improving structural stability. High-permeability, low-loss grain-oriented silicon steel is widely adopted to improve magnetic performance. Precision cutting and stacking processes minimize burrs and misalignment, while fully oblique joints or multi-step joint structures reduce magnetic flux distortion.

These improvements effectively lower no-load losses, reduce vibration and noise, and suppress localized overheating, thereby slowing insulation aging and improving long-term reliability.

Enhanced Winding Manufacturing Processes

Transformer windings must withstand significant electrodynamic forces during operation and fault conditions. Manufacturing upgrades emphasize the use of CNC winding equipment to ensure uniform turn dimensions and controlled tension. Reinforced end support structures enhance resistance to axial and radial stresses, while high-strength insulating paper and precision positioning processes improve overall mechanical stability.

As a result, the risk of winding deformation during operation or short circuits is significantly reduced, ensuring safer and more reliable transformer performance.

Optimization of the Insulation System Manufacturing Process

The oil-paper insulation system is one of the most critical factors determining transformer service life. Advanced manufacturing processes include pre-drying insulation materials and precisely controlling moisture content throughout production. Vacuum oil filling and vacuum holding processes are applied to minimize residual gas and moisture inside the insulation system.

In addition, optimized oil channel design improves insulating oil circulation and heat dissipation efficiency. Through strict insulation process control, partial discharge is effectively suppressed, and insulation aging is significantly delayed.

Improved Oil Treatment and Sealing Technology

High-reliability 35kV oil-immersed transformers increasingly rely on advanced oil treatment and sealing processes. Multi-stage vacuum oil filtration and degassing ensure high insulating oil purity. Highly reliable sealing structures reduce oil-gas exchange during operation, while improved welding and flange machining precision minimize leakage risks at the source.

Effective oil quality management and sealing performance extend maintenance intervals and greatly reduce the probability of unexpected failures.

Application of Advanced Testing and Intelligent Manufacturing Technologies

Online Monitoring and Quality Traceability

Intelligent monitoring technologies are now integrated into transformer manufacturing. Fiber optic temperature sensors enable real-time temperature monitoring during critical processes. Ultrasonic testing is used to verify winding compression quality, while robotic testing equipment ensures consistent and repeatable test results.

By establishing a full lifecycle quality traceability system, all manufacturing data can be tracked and analyzed, providing strong support for long-term reliability assurance.

Digital Process Control and Manufacturing Management

Digital manufacturing technologies further enhance process precision. Manufacturing Execution Systems monitor key parameters in real time, while big data analytics predict potential deviations and enable timely adjustments. This digital approach ensures stable product quality and continuous process optimization.

Upgrading the manufacturing processes of 35kV oil-immersed transformers is not limited to a single technology improvement. It represents a comprehensive enhancement covering materials selection, production processes, insulation systems, quality inspection, and manufacturing management. Through the adoption of advanced manufacturing and digital control technologies, transformer reliability and service life can be significantly improved.

At the same time, optimized manufacturing processes help reduce total lifecycle costs and enhance operational safety. With the ongoing advancement of intelligent manufacturing, 35kV oil-immersed transformers will continue to play an increasingly important role in smart grids and modern power systems.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri