Dry-Type vs. Oil-Immersed Transformer: Is a 20kV 2500kVA Dry-Type Transformer a Better Choice?

In industrial and commercial power distribution systems, selecting the right transformer type is a critical decision that directly affects safety, reliability, operating costs, and environmental compliance. For the widely used 20kV 2500kVA specification, users are often faced with a key question: should they choose a dry-type transformer or an oil-immersed transformer?

This article provides a comprehensive technical comparison of 20kV 2500kVA dry-type transformers and oil-immersed transformers, focusing on structure, cooling methods, safety performance, maintenance requirements, and typical application scenarios. The goal is to help decision-makers determine whether a dry-type transformer is the better choice for their specific project.

Structural Design and Cooling Method Comparison

20kV 2500kVA Dry-Type Transformer

Dry-type transformers at the 20kV 2500kVA level typically adopt epoxy resin cast windings, which provide excellent mechanical strength and insulation stability. The cooling method is usually natural air cooling (AN) or forced air cooling (AF), depending on load conditions and ambient temperature.

Because no insulating oil is used, dry-type transformers eliminate the risk of oil leakage and significantly reduce fire hazards. Their compact structure makes them especially suitable for indoor installation where space and safety requirements are strict.

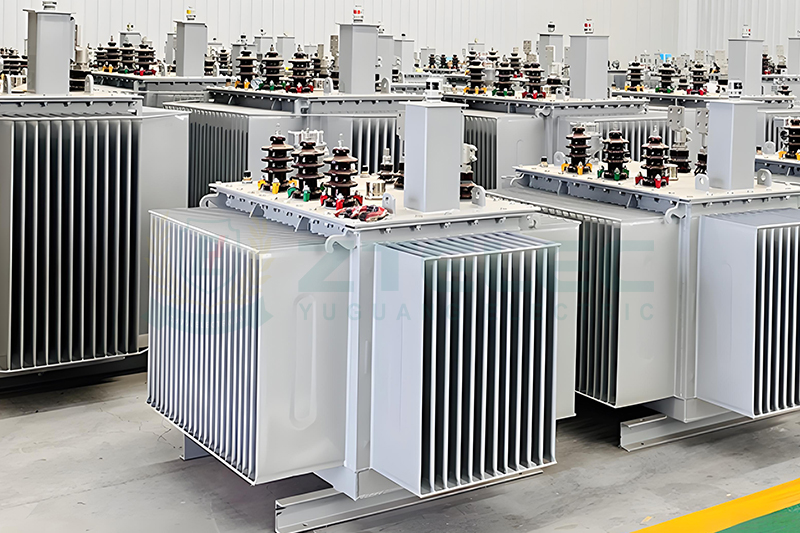

20kV 2500kVA Oil-Immersed Transformer

Oil-immersed transformers use mineral oil or environmentally friendly insulating oil to fully immerse the windings and core. Heat dissipation relies on natural or forced oil circulation, providing excellent cooling efficiency.

Thanks to the high heat capacity of transformer oil, oil-immersed transformers demonstrate strong overload capability and stable temperature control. However, they usually require outdoor installation or a dedicated transformer room equipped with fire protection and oil containment measures.

Performance Advantages of Dry-Type and Oil-Immersed Transformers

Key Advantages of 20kV 2500kVA Dry-Type Transformers

For medium-capacity applications such as 20kV 2500kVA, the safety advantages of dry-type transformers are particularly significant. The absence of oil eliminates leakage and fire risks, making them ideal for indoor and densely populated environments.

Dry-type transformers comply more easily with stringent building safety and fire protection regulations. They often do not require firewalls, oil pits, or complex firefighting systems, which simplifies overall system design.

From an environmental perspective, dry-type transformers avoid oil pollution risks altogether. Disposal at the end of service life is simpler, and there is no potential contamination of soil or groundwater.

Key Advantages of 20kV 2500kVA Oil-Immersed Transformers

Oil-immersed transformers offer superior heat dissipation performance, which is particularly beneficial for continuous high-load operation or high-temperature environments. For a 2500kVA rating, oil cooling allows better control of temperature rise.

In terms of initial investment, oil-immersed transformers are generally more economical. Their mature technology and widespread adoption also result in slightly higher long-term operating efficiency, helping to reduce electricity losses.

Oil-immersed transformers are well known for their reliability and durability. With a long operating history, they typically offer stronger overload capacity and a longer overall service life under stable operating conditions.

Operation and Maintenance Cost Comparison

Dry-Type Transformer Maintenance Characteristics

Dry-type transformers require minimal daily maintenance. There is no need for oil sampling, oil testing, or oil replacement, making them suitable for long-term unattended operation.

Over the entire lifecycle, maintenance costs are predictable and controllable, which aligns well with the needs of modern industrial and commercial users seeking simplified operation and reduced manpower input.

Oil-Immersed Transformer Maintenance Characteristics

Oil-immersed transformers require regular oil quality testing, including dielectric strength and moisture content analysis. Oil aging or contamination can increase maintenance frequency and labor costs.

Additionally, oil-immersed transformers place higher demands on the operating environment, including fire safety management and spill prevention measures.

Is a 20kV 2500kVA Dry-Type Transformer the Better Choice?

The answer is not absolute, but in most modern application scenarios, the overall advantages of 20kV 2500kVA dry-type transformers are more evident. Safety, environmental protection, installation flexibility, and reduced maintenance requirements are decisive factors driving their widespread adoption.

Dry-type transformers are particularly suitable for indoor installations such as commercial buildings, hospitals, data centers, urban substations, and locations with high population density. They are also ideal for projects with limited maintenance resources or strict environmental protection requirements.

Oil-immersed transformers remain a practical choice for outdoor substations with sufficient safety distance, cost-sensitive projects, and applications involving continuous high-load or high-temperature operation. In these scenarios, their cooling efficiency and long service life remain strong advantages.

In modern urban and commercial power distribution systems, the use of 20kV 2500kVA dry-type transformers is becoming increasingly common. Their core strengths lie in enhanced safety, environmental friendliness, and simplified installation and maintenance.

However, oil-immersed transformers still maintain a stable market presence in traditional industrial environments and budget-driven projects. Ultimately, the optimal transformer selection should be based on a comprehensive evaluation of technical requirements, safety regulations, installation conditions, and economic considerations rather than a one-size-fits-all conclusion.

- more+releated article

- 2025-12-24Dry-Type vs. Oil-Immersed Transformer: Is a 20

- 2025-12-22Do you know how to distinguish between good an

- 2025-12-22Why 66kV Power Transformers Are Indispensable

- 2025-12-20Composition and Classification of Insulating R

- 2025-12-20What Are the Key Factors Affecting the Perform

- 2025-12-20Upgrading Manufacturing Processes Enhances the

- 2025-12-20High-Efficiency and Energy-Saving 110 kV Oil-I

- 2025-12-18Application of G11 Epoxy Machined Components i

- 2025-12-18FR4 Epoxy Board: The First Choice for Insulati

- 2025-12-18Insulating Crepe Paper and Crepe Paper Pipes: