Bakelite Sheet in New Energy: Innovative Applications and Technological Advantages

Against the backdrop of the global energy structure accelerating its transformation towards sustainability, the new energy industry is booming at an unprecedented rate. With the continuous iteration and upgrading of technologies such as photovoltaics, wind power, and energy storage, the demand for high-performance materials is becoming increasingly stringent. As an insulation material with unique performance, bakelite sheet plays a vital role in many core links in the field of new energy with its excellent electrical insulation, mechanical strength, heat resistance, chemical corrosion resistance and good processing adaptability, and has effectively promoted technological innovation and sustainable development of the industry.

Core performance advantages of bakelite sheet

1. Excellent electrical insulation properties

Bakelite sheet has extremely high resistivity and breakdown voltage, which can effectively isolate current and build a solid barrier for the safe and stable operation of circuits and equipment. In complex electrical environments, its insulation performance can significantly reduce the risk of leakage and ensure system safety.

2. Excellent heat resistance and stability

In the face of high temperature environments, bakelite sheet exhibits good physical and chemical stability, is not easy to deform or burn, and can calmly cope with the high temperature conditions generated during the operation of new energy equipment to ensure that the performance of the equipment is not affected.

3. Strong mechanical strength

After high temperature and high pressure processing, bakelite sheet has excellent tensile, compressive and bending resistance. It can withstand large mechanical stress, remain stable in complex mechanical structures, and reduce damage caused by external forces.

4. Excellent wear and corrosion resistance

The surface of bakelite sheet is hard and wear-resistant, and has good tolerance to a variety of chemicals. Even in harsh working environments, it can maintain stable performance for a long time, effectively extending the service life of the equipment.

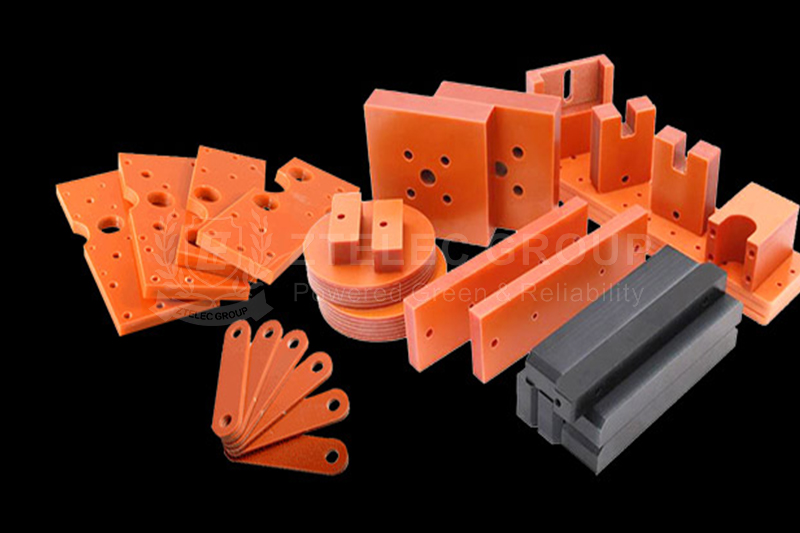

5. Good processing adaptability

Bakelite sheet is easy to cut, drill and shape. And it can be processed into various shapes and sizes according to the needs of different application scenarios, which provides convenience for diversified product design.

Diverse applications of bakelite sheet in the field of new energy

1. Photovoltaic module manufacturing

In the production process of solar photovoltaic modules, laminators are key equipment for module encapsulation. Bakelite sheet is often used to make the upper and lower templates of the laminator. Under high temperature and high pressure, it can firmly support and accurately press materials such as photovoltaic cells, glass, EVA film and backplane to ensure that the layers are tightly fitted. Its flat and smooth surface can effectively avoid defects such as bubbles and delamination, significantly improve the encapsulation quality of photovoltaic modules, and thus improve power generation efficiency and service life. Taking a large photovoltaic module manufacturer as an example. After using bakelite sheet templates, the yield rate of the module increased by 15%, and the power generation efficiency was also significantly improved.

2. Internal insulation guarantee of photovoltaic inverters

As the core device for converting direct current into alternating current, the photovoltaic inverter has a sophisticated and complex internal circuit and extremely strict insulation requirements. Bakelite sheet is widely used in the internal insulation components of the inverter, such as partitions and brackets, which can accurately isolate circuits with different potentials and effectively prevent electrical breakdown and short circuit failures. At the same time, its excellent heat resistance enables it to adapt to the high temperature environment generated by the long-term operation of the inverter, ensuring stable and reliable operation of the equipment and providing solid guarantee for the safe and efficient operation of the photovoltaic power generation system.

3. Photovoltaic tracking system component support

In order to improve the power generation efficiency of photovoltaic power stations, more and more power stations have adopted photovoltaic tracking systems. With good mechanical strength and wear resistance, bakelite sheet is used to manufacture mechanical transmission and support structure components such as gears, sleeves, and brackets of the tracking system. These components can ensure the stable operation of the tracking system, effectively reduce component wear, and reduce failure rate and maintenance costs. According to actual application data, the maintenance cycle of the photovoltaic tracking system using bakelite sheet components has been extended by 30%, and the overall operating cost has been reduced by 20%.

Important applications in the field of wind power generation

1. The key role of stator and rotor insulation of wind turbines

As the core equipment of the wind power generation system, the insulation performance of the stator and rotor of the wind turbine directly determines the efficiency and reliability of the generator. Bakery boards are often processed into insulating gaskets, slot wedges and other components to isolate the winding and the core, effectively prevent current leakage and eddy current loss, and significantly improve the energy conversion efficiency of the generator. Its excellent heat resistance and corrosion resistance enable it to operate stably for a long time in harsh natural environments such as wind, sun, and high humidity, ensuring the continuous and efficient power generation of the wind power generation system.

2. Internal insulation protection of wind power converters

Wind power converters are responsible for converting the unstable alternating current generated by wind turbines into stable electric energy and incorporating it into the power grid. The internal high-voltage circuits have extremely high requirements for insulation protection. Bakelite sheet is used to make insulating partitions, busbar clamps and other components inside the converter, providing reliable insulation protection for the circuit and effectively reducing the probability of electrical failures. In addition, the flame retardant properties of bakelite sheet fully meet the strict standards of the wind power industry for equipment safety, safeguarding the safe operation of wind power converters.

Wide application in the field of energy storage

1. Insulation protection of battery management system (BMS)

In energy storage battery systems, the battery management system bears the heavy responsibility of accurately monitoring and managing the battery charging and discharging process, and its reliability is crucial. Bakelite sheet is widely used in BMS circuit board insulation support, terminal insulation sheath and other components. With its excellent insulation performance, it effectively prevents short circuits between components with different potentials inside the battery pack, protects the BMS circuit board from electrical breakdown damage, greatly improves the stability and reliability of the battery management system, and ensures the safe and efficient operation of the energy storage battery system.

2. Structural support for energy storage battery modules

Energy storage battery modules are composed of multiple battery cells and require strong and reliable structural parts for fixing and supporting. Bakelite sheet can be processed into structural components such as end plates and side plates of battery modules. It can not only provide sufficient mechanical strength to ensure the structural stability of battery modules during transportation and use, but also has good insulation performance, effectively avoiding electrical interference and short circuit risks between battery cells. At the same time, its chemical corrosion resistance enables it to resist the erosion of chemical substances such as battery electrolyte, significantly extending the service life of battery modules.

3. Insulation protection of electrical cabinets of energy storage systems

The electrical cabinets of energy storage systems integrate a large number of electrical equipment and lines, and have strict requirements for insulation and protection. Bakelite sheet is used to make insulating partitions, mounting brackets, door panels and other components of electrical cabinets, which effectively prevent electrical accidents by physically isolating electrical equipment of different voltage levels. Its flame retardant and arc resistant properties further enhance the fire safety performance of electrical cabinets, providing solid protection for the overall safe operation of energy storage systems.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen