Know Everything About 3240 Epoxy Sheet

As a kind of high performance composite material, 3240 epoxy sheet plays an important role in modern industry. Understanding 3240 epoxy sheet helps us to use it better.

What is 3240 epoxy sheet?

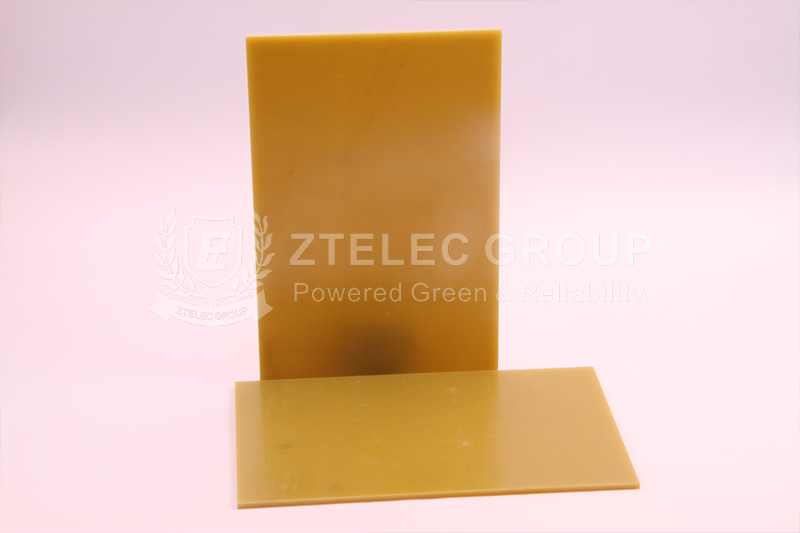

3240 epoxy sheet is an insulating material that mainly composed of electrical fiber glass cloth impregnated with epoxy resin and processed through drying and hot pressing. The temperature resistance grade of 3240 epoxy sheet is Class B, and colors include yellow, red, green, and black. It complies with the standard GB/T1303.1-1998 (natural color). The surface of 3240 epoxy sheet should be smooth, free of bubbles, pits, and wrinkles, with allowable defects that do not affect its use, such as scratches, indentations, stains, and minor spots. The edges should be neatly cut, and the end faces should be free from delamination and cracks. The thickness of 3240 epoxy sheet is typically 0.5 to 50mm, but can also be produced in thicknesses of 50 to 150mm as required.

What is epoxy resin?

Epoxy resin refers to organic high molecular compounds containing two or more epoxy groups in their molecules, with relatively low molecular weights in most cases. The molecular structure of epoxy resin is characterized by the presence of active epoxy groups in the molecular chain, which can be located at the end, middle, or in a cyclic structure.

What are the features?

1. Stable physical properties

Low shrinkage: During the curing process, the reaction of the 3240 epoxy sheet with the curing agent is carried out by direct addition reaction or ring-opening polymerization of the epoxy group, and no water or other volatile byproducts are released, so the shrinkage is extremely low (less than 2%), which helps to reduce deformation and stress concentration during the processing.

High strength: The cured epoxy resin system has excellent mechanical properties, high mechanical strength at medium temperature, which can make it withstand large loads and not easy to break.

Good dimensional stability: Due to its low shrinkage and high strength characteristics, the 3240 epoxy sheet can maintain a stable size during long-term use and is not easy to deform or warp.

2.Excellent electrical performance

High dielectric properties: The cured epoxy resin system has a very high dielectric constant and low dielectric loss, which can effectively isolate the electric field and prevent current leakage.

Arc resistance: Under the action of the arc, the 3240 epoxy sheet can maintain stable insulation performance and is not easy to be broken down or melted, so as to protect the safety of the circuit and equipment.

Surface leakage resistance: The surface is smooth and has no pores, which can effectively prevent the current from flowing on the surface and improve the insulation effect.

3.Excellent processing performance

Easy cutting and drilling: Machining operations such as cutting and drilling 3240 epoxy sheets can be easily performed with the right tools and processes.

Strong plasticity: Through heating and pressure and other process means, the 3240 epoxy sheet can be bent, folded and other molding operations to meet the needs of various complex shapes.

High bonding strength: The polar hydroxyl and ether bonds inherent in the molecular chain of 3240 epoxy sheet make it have high adhesion to various substances, which is convenient for firm bonding with other materials.

4.Strong environmental adaptability

High temperature resistance grade: Its temperature resistance grade reaches B, which can maintain stable insulation performance in high temperature environment.

Good corrosion resistance: 3240 epoxy sheet has good resistance to corrosive media such as oil, water, acid and alkali, and can be used in humid and corrosive environment for a long time without being affected.

Excellent flame retardant performance: Some3240 epoxy sheet products also have flame retardant performance, which can slow down the spread of fire in the fire and protect the safety of equipment and personnel.

Application of 3240 epoxy sheet

1. Motor and electrical equipment

Insulation structural parts: 3240 epoxy sheet has high insulation resistance and voltage strength and can effectively prevent current leakage and short circuit, so it is widely used in motors, electrical equipment as insulation structural parts.

Winding support: In large transformers, 3240 epoxy sheet is often used as an insulating support for the winding to ensure stable operation of the transformer under high voltage environment.

2.PCB testing and manufacturing

PCB test board: 3240 epoxy sheet is widely used in PCB test process as a test board because of its good insulation performance and machinability.

Drilling pad: In the PCB drilling process, 3240 epoxy sheet can be used as a pad to improve the accuracy and efficiency of drilling.

3.High temperature and humid environment applications

High temperature environment: 3240 epoxy sheet can maintain good physical and chemical properties and no deformation, no softening in high temperature environment, so it is widely used in industrial heating equipment, high temperature furnace and other fields as heat insulation and insulation materials.

Wet environment: Its good moisture resistance makes the 3240 epoxy sheet can maintain stable performance in wet environment, so it can be used to make equipment parts that work in wet environmental conditions.

3240 epoxy sheet processing method

Drilling: It is a common processing method in PCB circuit board factories, which is suitable for PCB test fixtures and post-processing.

Computer numerical control: That is, CNC or CNC machining, has flexible, fast, powerful characteristics. It is suitable for processing insulation gaskets, insulation rods and other small workpiece.

Cutting: It is a common processing method on the market. And it is used to cut the plate into the required size.

3240 epoxy sheet identification method

The identification of its quality can start from the appearance. The surface of a good sheet should be smooth, free of bubbles, cracks, and uniform color. Secondly, it can be judged by touch. A good epoxy sheet feels hard and tough and is not easy to break. Although these preliminary sensory identifications are simple, they can already exclude most inferior products.

Further ingredient identification requires the help of professional equipment and technology. For example, the use of an infrared spectrometer can detect specific chemical bonds in epoxy resin to determine its composition. This method has high accuracy, but requires professional operation and is relatively expensive. Another method is to perform thermogravimetric analysis to infer the composition ratio of the sample by measuring the weight loss of the sample at different temperatures. This method is particularly effective for detecting the content of curing agents and other additives.

In addition to instrumental analysis, it can also be identified through combustion tests. Epoxy resin produces special smoke and odor when burning, and the residue is usually powdery rather than viscous liquid. Although this method is simple, it needs to pay attention to safety and avoid pollution to the environment.

How to choose 3240 epoxy sheet?

In actual industrial applications, when choosing 3240 epoxy sheet, it is also necessary to consider the performance indicators of 3240 epoxy sheet, such as voltage resistance, heat resistance, corrosion resistance, etc. These performance parameters are usually obtained through standardized test methods and are an important basis for evaluating the quality of epoxy sheets. For example, the withstand voltage test can test the insulation performance of the sheet, while the heat aging test can evaluate its durability after long-term use.

When choosing, its application scenarios and processing requirements should also be considered. Sheets of different thicknesses and specifications are suitable for different purposes, such as insulating gaskets for electronic equipment, support plates for mechanical structures, etc. At the same time, good epoxy sheets should be easy to cut and drill to meet complex processing requirements.

In summary, identifying the quality of 3240 epoxy sheets is a multifaceted evaluation process involving multiple links such as appearance inspection, physical property testing, chemical composition analysis, and performance index verification. Through these comprehensive considerations, consumers can more accurately judge the pros and cons of 3240 epoxy sheets and make wise choices. In the electronics and insulation materials industry, mastering this knowledge is of great practical significance for ensuring product quality and engineering safety.

Ztelec Group is a professional manufacturer of high-quality electrical insulation materials with more than sixty-five years of manufacturing experience. If you need more product information and quotes, please contact us.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen