What is Insulation G-11 Laminates, Tubes, Sheets and Fabricated Parts

2024-08-22 16:50 | By: ZTELEC-www.ztelecgroup.com | 64click

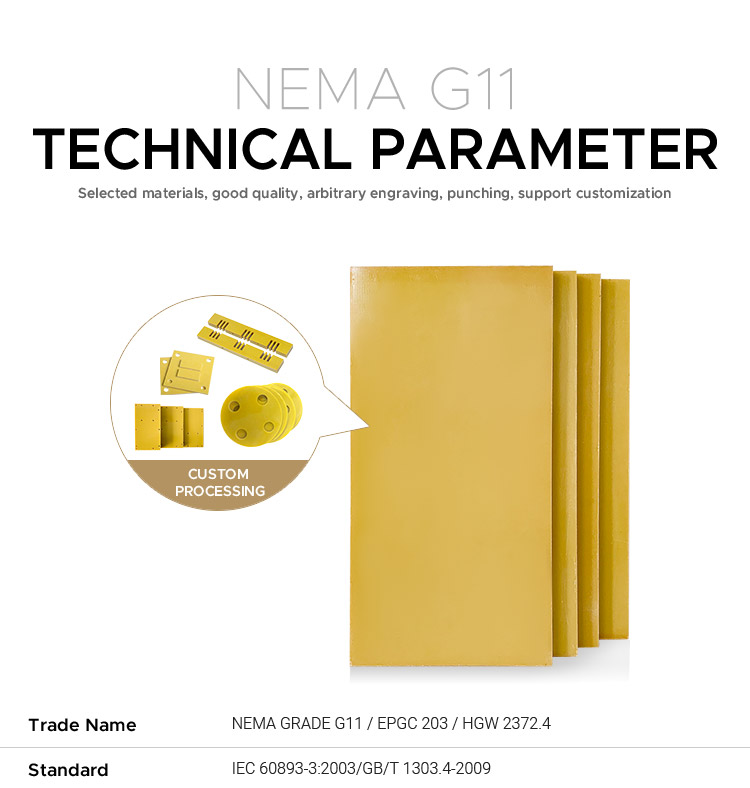

G-11 is a high-performance glass epoxy laminate known for its exceptional mechanical and electrical properties. This material is widely used in various industries due to its ability to withstand high temperatures and humidity, making it suitable for demanding applications. Below is an overview of G-11 laminates, tubes, sheets, and fabricated parts.

What is G-11 Material?

G-11 is a thermosetting composite made from continuous filament glass cloth and epoxy resin. It is classified under the NEMA (National Electrical Manufacturers Association) standards, specifically designed for applications requiring high strength and electrical insulation. G-11 exhibits superior properties compared to G-10, particularly in terms of temperature resistance and mechanical strength at elevated temperatures.

Key Properties of G-11

Temperature Resistance: G-11 can operate at temperatures up to 180°C (356°F) for Class H and 150°C (302°F) for Class F.

Mechanical Strength: It retains significant structural integrity even at high temperatures, maintaining over half of its strength at elevated conditions.

Electrical Insulation: G-11 offers excellent dielectric strength and low moisture absorption, making it ideal for electrical applications.

Dimensional Stability: The material exhibits minimal warping or deformation, ensuring consistent performance in various environments.

Forms of G-11

1. G-11 Laminates

G-11 laminates are available in various thicknesses and sizes, suitable for different applications. These laminates can be machined into specific shapes and sizes according to project requirements.

2. G-11 Tubes

G-11 tubes are manufactured using the same epoxy-saturated glass cloth as the laminates. They are typically made to order and can be wound over mandrels, providing high strength and thermal stability for applications requiring cylindrical components.

3. G-11 Sheets

G-11 sheets come in a range of thicknesses, from thin sheets to thicker slabs, allowing for versatile use in various applications. These sheets can be cut and machined to fit specific requirements.

4. Fabricated Parts

G-11 can be fabricated into various components, such as terminal boards, electric rotor insulation, and parts for electronic test equipment. Due to its robust properties, G-11 is often used in high-humidity environments and applications requiring high mechanical strength.

Applications of G-11

G-11's unique properties make it suitable for a wide range of applications, including:

Electrical Equipment: Used in power generation components, circuit board holders, and terminal boards.

Aerospace and Defense: Ideal for structural components and insulators in aircraft and rocket systems.

Industrial Manufacturing: Employed in high-temperature and high-humidity applications, such as washers and sleeves.

Medical Devices: Utilized in diagnostic equipment and surgical tools due to its chemical resistance and low moisture absorption.

Conclusion

G-11 materials, including laminates, tubes, sheets, and fabricated parts, offer exceptional performance characteristics that make them suitable for various demanding applications. Their high mechanical strength, excellent electrical insulation, and temperature resistance make G-11 a preferred choice in industries such as aerospace, electronics, and medical devices. As technology advances and the demand for high-performance materials increases, G-11 will continue to play a vital role in engineering and manufacturing solutions

tags:insulation failure transformertransformer short circuittransformer overheatingtransformer overloadtransformer maintenance

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri