Quality Control and Inspection Standards for Epoxy Boards

Epoxy boards, with FR-4 epoxy glass cloth laminates as a typical representative, if they have quality defects such as delamination, bubbles, uneven thickness, or substandard electrical performance, will cause circuit short circuits, equipment failures, and in severe cases, safety accidents. A sound quality control system not only ensures that products meet specifications but also improves production yield, reduces costs, and enhances brand reputation.

Quality Control of Epoxy Boards

The quality control of epoxy boards should cover the entire production process, and the specific implementation is as follows:

1. Raw Material Control

Screen core raw materials such as epoxy resin and glass fiber cloth, and verify quality certification documents.

Conduct sampling tests on key indicators such as the viscosity of epoxy resin and the uniformity of glass fiber cloth thickness to ensure the stability of raw material quality.

2. Production Process Monitoring

During the pressing process, precisely control process parameters such as temperature, pressure, and holding time, and strictly follow the established process standards.

Strengthen on-site production management, keep the environment clean, and prevent impurities from mixing in.

3. Finished Product Inspection

Conduct a full visual inspection to identify surface defects such as bubbles, scratches, and cracks.

Test mechanical and electrical properties through methods such as bending strength tests and insulation resistance tests. Conduct sampling tests in accordance with relevant standards to determine the product's qualified status.

4. Quality Traceability System

Establish a traceability system covering the entire production process. Record information such as raw material procurement, process parameters, and inspection results to ensure that when quality issues arise, the causes can be quickly identified and rectified.

Analysis of Inspection Items and Standards for Epoxy Boards

1. Electrical Strength

Electrical strength refers to the ability of epoxy boards to withstand high voltage without breakdown. The inspection standards include GB/T 1408 and IEC 60243.

The unit of measurement is kV/mm (kilovolts per millimeter). This value directly reflects the insulation performance of the material and is a core inspection indicator.

2. Mechanical Properties

Mechanical properties mainly include bending strength and impact strength:

• Bending strength: It characterizes the ability of the board to withstand bending loads;

• Impact strength: It characterizes the ability of the board to resist impact and avoid brittle fracture.

The inspection standards are GB/T 9341, GB/T 1043, and ASTM D790. The units of measurement are MPa (bending strength) and kJ/m² (impact strength), respectively. The higher the values, the better the processing adaptability and durability of the product.

3. Heat Resistance

Heat resistance refers to the ability of epoxy boards to maintain stable performance in high-temperature environments. The core evaluation indicator is the heat deflection temperature, and the inspection standard is GB/T 1634 and ASTM D648.

The unit of measurement is °C. The higher the heat deflection temperature, the better the shape stability and strength retention of the material in high-temperature conditions.

4. Other Important Inspection Indicators

Water Absorption: It measures the performance changes of the board after absorbing water, and the execution standard is IEC 60893. Low water absorption can ensure the stability of the material's performance in humid environments.

Flammability: It measures the fire resistance of the material, and the execution standard is UL94. V-0 grade is a commonly used flammability rating.

Surface Resistivity and Volume Resistivity: They measure the insulation performance of the material, and the execution standard is IEC 60093.

Acceptance Criteria for Epoxy Boards

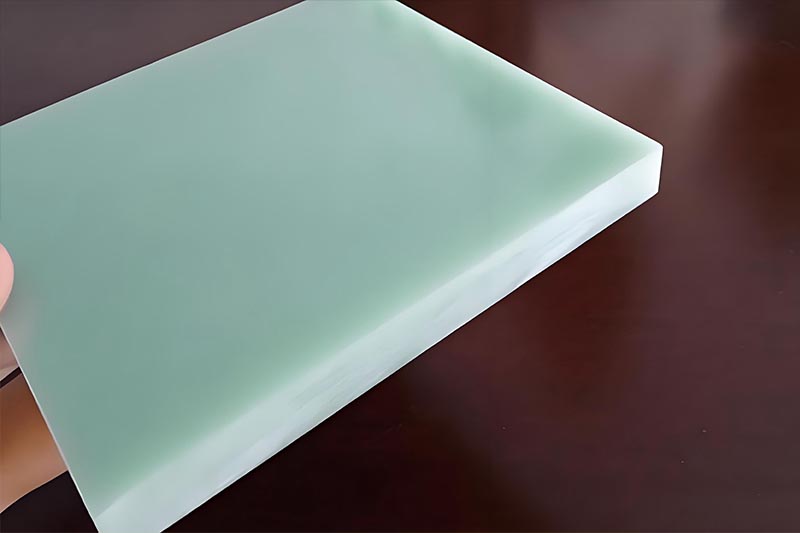

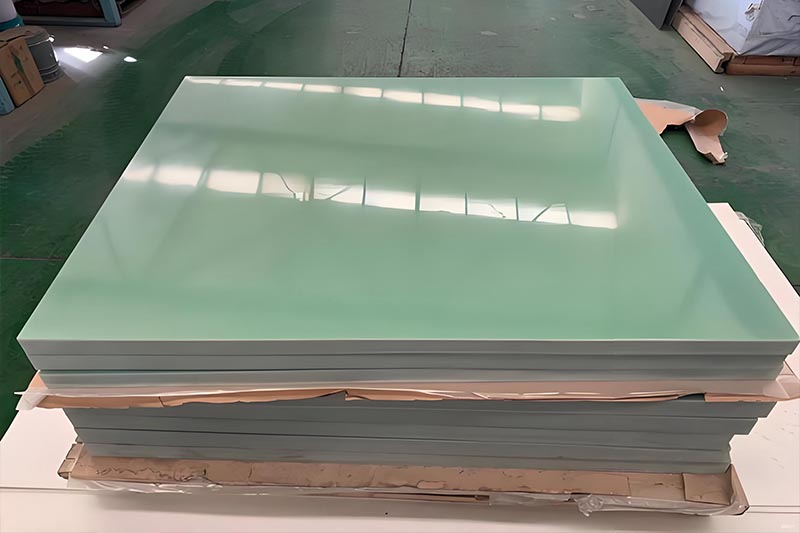

Appearance quality:

The surface of the product should be smooth, free of bubbles, cracks, impurities and other defects.

The color should be uniform with no obvious color difference.

The edges of the board should be neat and undamaged.

Dimensional accuracy:

Measure key dimensions such as length, width and thickness to ensure compliance with specified specifications.

For applications requiring precise assembly, dimensional deviations should be strictly controlled.

Physical properties:

Test hardness, tensile strength, compressive strength, flexural strength and other indicators through professional equipment to ensure they meet usage requirements.

Chemical composition:

Verify the compliance of the epoxy resin and additive ratios, confirm that no harmful components exceed standards, and ensure the long-term stability of the material.

The quality control and inspection standards for epoxy boards are the foundation for ensuring product performance meets standards and operates reliably over the long term. The manufacturer and the purchaser need to clearly define the relevant standards and strictly implement them. They should particularly focus on the detection of key performance indicators. Only by choosing suppliers with a sound quality management system can the epoxy boards used meet the requirements of the application scenarios.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri