Industrial-Grade G10/G11/FR4 Insulation Laminate Supplier

As the performance requirements for insulation materials in the industrial electrical equipment industry continue to rise, G10, G11, and FR4 insulation laminates have gradually become the preferred insulation materials for high-voltage electrical appliances, transformers, circuit breakers, and various precision machinery. As a professional supplier, we can provide industrial-grade laminates in various specifications and thicknesses to ensure optimal performance for our customers in different application scenarios.

G10, G11, and FR4: Differences Explained

1. G10 Laminate

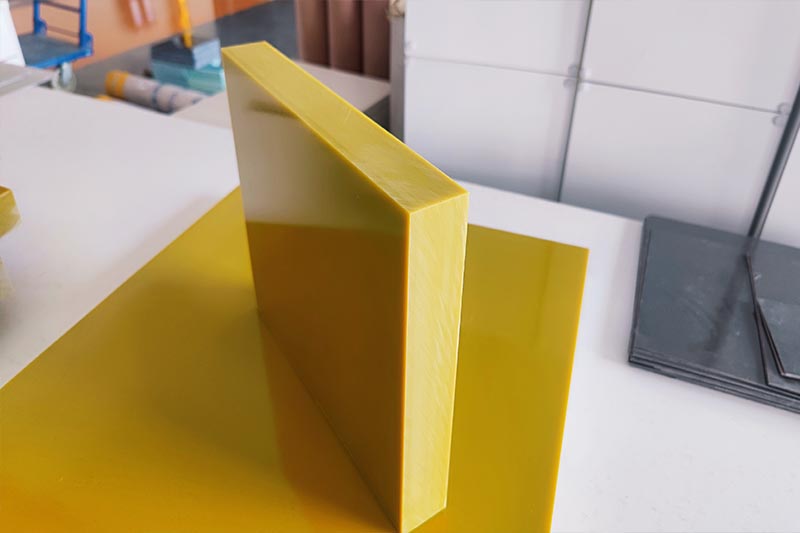

This laminate uses fiberglass cloth as the base material, combined with epoxy resin, and is formed through a high-temperature and high-pressure process.

It is suitable for insulating components of high-voltage electrical equipment, mechanical gears, insulating gaskets, and other products.

2. G11 Laminate

Its base material is similar to G10, but the key difference is that it uses epoxy resin with a higher heat distortion temperature.

This laminate is suitable for the insulation structures of high-temperature motors, welding equipment, thermal instruments, and other products.

3. FR4 Laminate

This laminate is made of flame-retardant epoxy resin and fiberglass cloth.

It is widely used in PCB substrates, electronic device housings, and insulating support components for power modules.

Core Performance Advantages of G10/G11/FR4 Laminates

1. Superior Electrical Insulation Performance

G10, G11, and FR4 laminates all possess extremely high dielectric strength, effectively preventing short circuits or breakdowns within electrical equipment. G11 laminate, in particular, exhibits superior heat resistance compared to G10, enabling long-term stable operation in high-temperature environments.

2. Excellent High Mechanical Strength

These laminates demonstrate outstanding tensile, flexural, and impact strength, fully meeting the stringent structural strength requirements of industrial equipment.

3. Heat and Chemical Corrosion Resistance

FR4 and G11 laminates have high heat resistance ratings. They can withstand prolonged high-temperature environments of approximately 200°C and possess excellent resistance to acids, alkalis, oils, and other chemicals. They are suitable for use in complex operating conditions.

4. Flexible Processing Adaptability

These laminates support various processing methods such as drilling, cutting, and milling. Manufacturers can customize various shapes and sizes according to customer needs, precisely matching the installation requirements of customer equipment.

How to Choose a Reliable Industrial-Grade Insulation Laminate Supplier?

1.Certification and Standards Compliance:

Reputable suppliers should possess relevant certifications such as UL, ISO 9001, and RoHS to ensure that the materials supplied comply with international safety and environmental standards.

2.Product Performance Stability:

Reliable suppliers will ensure consistency in thickness tolerance, insulation strength, and mechanical properties of each batch of G10/G11/FR4 sheets through a rigorous quality control system.

3.Customized Processing Capabilities:

Professional suppliers can provide customized processing services such as precise cutting, drilling, and grinding according to specific customer needs, helping customers reduce secondary processing costs.

4.Technical Support and After-Sales Service:

Trustworthy suppliers should have a professional team to provide customers with material selection advice, application solution optimization services, and rapid response to after-sales needs.

Wide Applications of G10/G11/FR4 Laminates

Transformers and Dry-Type Transformers: G10/G11/FR4 laminates serve as insulation supports and spacers, ensuring the long-term safe operation of transformers.

High-voltage switchgear (GIS/GCS): These sheets are used for isolation, support, and insulation protection of equipment, ensuring operational stability.

Precision mechanical and electronic equipment: In scenarios with dual requirements for strength and insulation performance, they provide reliable solutions for equipment.

Power and new energy equipment: These sheets are suitable for various new energy systems such as wind power, photovoltaics, and high-voltage direct current transmission.

Why Choose Us?

Strict Quality Control: We strictly adhere to international standards such as IEC and UL in our production processes, ensuring stable and reliable performance in every batch.

Extensive Experience: We have over 65 years of experience in manufacturing industrial insulation materials, with a service network covering customers worldwide.

Customization Services: We support personalized customization of thickness, size, and performance grade to meet diverse industrial needs.

Technical Support: We provide professional engineering consulting and application solutions to help customers optimize product design.

FAQs

Q1: What is the core difference between FR4 and G10?

A1: FR4 is a flame-retardant type of G10. It achieves its flame-retardant effect by adding flame retardants and has passed UL94 V-0 certification.

Q2: Should I choose G11 or FR4 for high-temperature applications?

A2: For continuous high-temperature conditions, we recommend prioritizing G11. If both temperature resistance and flame retardancy requirements are needed, high Tg FR4 can be selected.

Q3: What processing treatments can be performed on this type of sheet?

A3: These materials support conventional machining processes such as cutting, drilling, and milling. Reputable suppliers offer one-stop customized machining services.

As a professional supplier of industrial-grade G10/G11/FR4 insulation laminates, we are committed to providing customers with high-quality, stable, and reliable insulation materials. Please contact us immediately for professional technical support and customized solutions to help your electrical equipment operate safely and efficiently.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri