Transformer Insulation DMD Paper:Comprehensive Guide

In the core sections of power transformers, there is a critical material known as transformer insulation DMD paper. It plays an essential role in ensuring the stable, efficient, and long-term operation of transformers. For electrical engineers, transformer designers, procurement specialists, and students specializing in insulation materials, this article provides a comprehensive overview of DMD paper, including its definition, structure, key properties, application scenarios, selection guidelines etc.

What Is Transformer Insulation DMD Paper?

Transformer insulation DMD paper, short for Polyester Film – Polyester Fiber Non-woven Fabric – Polyester Film Composite Insulation Paper (Dacron-Mylar-Dacron), is a flexible laminated insulation material composed of three layers:

Top and bottom layers: Polyester film (Mylar). These layers provide excellent electrical insulation strength and mechanical strength.

Middle layer: Polyester fiber non-woven fabric (Dacron). This layer enhances flexibility, tear resistance, and impregnation capability.

This three-layer composite structure combines the insulation performance of polyester film with the toughness of fiber fabric. Therefore, DMD paper is widely used as inter-turn, inter-layer, and inter-phase insulation in oil-immersed and dry-type transformers.

Why Is DMD Paper a Common Insulation Material for Transformers?

DMD paper offers a well-balanced set of properties that meet the operational requirements of transformers. Its advantages include:

1. Excellent Electrical Properties

It has high dielectric strength, allowing it to withstand strong electrical fields without breakdown, ensuring reliable inter-turn and inter-layer insulation.

Its dielectric constant remains stable across the temperature and frequency ranges encountered during transformer operation, ensuring consistent electrical performance.

2. Outstanding Mechanical Properties

It has high tensile strength, making it resistant to breaking under the electromagnetic forces generated by transformer windings.

Its flexibility and tear resistance make it easy to wrap around copper conductors or cores while minimizing damage, thereby improving production efficiency.

3. Strong Thermal Stability

DMD paper is available in thermal classes B (130°C), F (155°C), and H (180°C). It can maintain stable performance under the high-temperature conditions of transformer operation and effectively slows down thermal aging.

4. Excellent Impregnation Capability

The fiber layer in the middle can rapidly and thoroughly absorb transformer insulating oil or impregnating resin. This helps create a dense insulation system, eliminates air bubbles, and extends the lifespan of the insulation structure.

5. Superior Chemical Resistance

DMD paper is resistant to transformer oil, chemical solvents, and mild acids and alkalis, ensuring long-term stability under complex operating conditions.

Application Scenarios of DMD Insulation Paper

1. Interlayer Insulation for Low-Voltage Coils

DMD paper is commonly used as an insulation material for the low-voltage coils of dry-type transformers. In particular, epoxy-resin–coated DMD insulation paper, after vacuum impregnation, can bond tightly with copper foil, forming an insulation structure with low shrinkage and high bonding strength.

2. Motor Slot Insulation and Inter-Turn Insulation

It can be used for stator slot insulation, inter-phase insulation, and rotor winding protection in F-class motors. Its thermal resistance matches the long-term operating requirements of motors, and it can also be die-cut to fit different slot designs.

3. Insulating Pads for Special Electrical Equipment

In equipment such as current transformers and switchgear, DMD paper serves as an insulating barrier, providing high-voltage resistance and corona protection. For example, diamond-dotted DMD paper, designed with point-pattern resin coating, allows transformer oil penetration and gas discharge in oil-immersed transformers, effectively preventing partial discharge issues.

Benefits of Using DMD Insulation Paper in Transformers

Choosing DMD insulation paper in transformer design brings multiple practical benefits for both manufacturers and end users:

♦ It reduces the risk of insulation-related failures, ensuring the safe operation of the power grid and electrical equipment.

♦ It extends the transformer’s service life, lowers replacement frequency, and helps reduce overall operating costs.

♦ Its high dielectric strength allows for reduced insulation thickness, enabling transformer miniaturization, compact construction, and higher power density.

♦ Its soft and flexible structure makes cutting, punching, and winding easier, simplifying coil manufacturing and improving production efficiency and consistency.

Although DMD paper is more expensive than ordinary insulation paper, its total cost of ownership (TCO) is more advantageous due to improved lifespan and reliability, offsetting the difference in unit price.

The DMD Insulation Paper Manufacturing Process

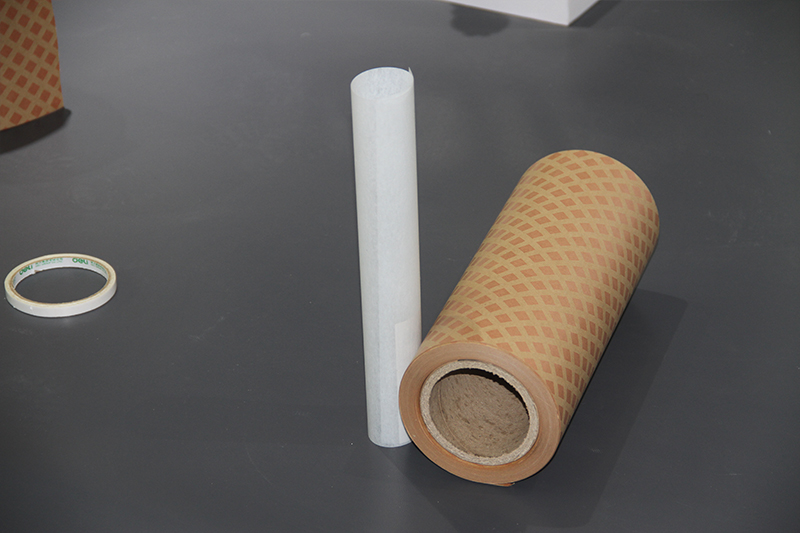

The DMD insulation paper manufacturing process is precise and requires strict control. The main steps are as follows:

1. Raw Material Preparation

· High-quality polyester film (Mylar) rolls and polyester fiber (Dacron) non-woven fabric rolls are prepared.

· All raw materials undergo rigorous incoming inspection to ensure that their dielectric properties, thickness, and uniformity meet standard requirements.

2. Gluing and Lamination

· A high-performance adhesive (typically epoxy or polyester adhesive) is evenly applied to both sides of the polyester film.

· Two layers of polyester fiber non-woven fabric are precisely laminated to the coated polyester film using a heated roller. This step requires extremely strict control of temperature, pressure, and speed to ensure a bubble-free, delamination-free, and secure bond.

3. Curing and Aging

· The laminated materials enter a heated tunnel (curing oven) to fully cure the adhesive, forming a permanent three-layer composite structure.

· The materials may then be allowed to rest for a period of time to achieve final bond strength.

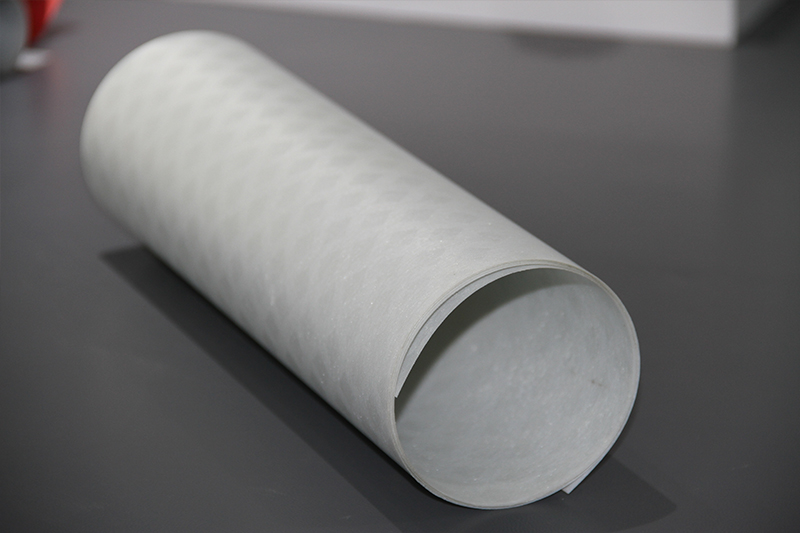

4. Cooling and Winding

The solidified material is cooled and shaped by cooling rollers before being wound into wide rolls by an automatic winder for subsequent slitting.

5. Slitting and Testing

· Large rolls of DMD material are slit into the required widths and lengths according to customer order specifications.

· Quality control is a core part of the manufacturing process. Numerous tests are performed throughout the production process, including dielectric strength testing, thickness and uniformity testing, adhesive strength testing, and tensile strength testing. Only products that pass all tests are packaged and shipped.

Price of DMD Insulation Paper

Key Conclusion: The price of DMD insulation paper varies due to multiple factors, generally ranging from 30 RMB to over 100 RMB per kilogram.

1.Main Factors Affecting the Price:

♦ Model and Thickness

DMD paper is available in models such as DMD-1, DMD-2, DMD-3, and in various thicknesses such as 0.15 mm, 0.20 mm, 0.25 mm, etc.

Different models and thicknesses show significant price differences — generally, the thicker the material and the higher the performance requirements, the higher the price.

♦ Brand and Quality

Imported brands are priced higher than domestic ones. Differences in manufacturing processes and quality control standards among suppliers also influence pricing.

♦ Purchase Quantity

Bulk orders are cheaper than retail purchases. The larger the quantity, the lower the unit price.

♦ Market Conditions

Price fluctuations of chemical raw materials—such as polyester film and aramid fiber—directly affect the production cost of DMD insulation paper, thus influencing its market price.

2.Purchasing Recommendations:

Buyers should first determine the required model, thickness, and performance specifications of the DMD insulation paper.

It is advisable to contact multiple manufacturers or distributors and provide detailed requirements to obtain real-time quotations for comparison.

Channels for Purchasing DMD Insulation Paper

1. Direct Factory Sales (Recommended)

This channel is ideal for motor manufacturers, transformer factories, reactor producers, and other high-volume buyers.

For example, ZTelecgroup:

Over 65 years of experience in insulation material manufacturing

Certified with ISO, CE, RoHS

Supplies a full range of DMD insulation papers for dry-type transformers and motors

Supports customization of width, thickness, thermal class

Suitable for non-standard projects, large-volume orders, and multinational supply-chain cooperation

2. Cross-Border E-Commerce Platforms

Platforms such as Alibaba International and Made-in-China are suitable for overseas buyers purchasing small batches. Buyers can compare prices, delivery times, and supplier capabilities directly on these platforms.

3. Local Industrial Material Distributors

This channel is ideal for customers needing immediate delivery or urgent usage, offering fast access to DMD paper.

4. EPC Projects / Transformer Package Suppliers

This method is suitable for large-scale projects in new energy, petrochemical, and substation sectors. Unified procurement through EPC or transformer system integrators helps ensure project progress and consistency of insulation materials.

Industry Value of DMD Insulation Paper

DMD insulation paper is safe, efficient, heat-resistant, and cost-effective, and it will continue to be widely used in the electrical, motor, and new energy sectors in 2025.

As a critical insulation material, transformer DMD paper ensures the safe operation of modern power systems. With excellent electrical, mechanical, and thermal properties, it is key to achieving compact design, high efficiency, and long service life in transformers.

Whether you design new transformers or maintain existing equipment, selecting the right DMD paper is essential for ensuring stable power supply.

Looking for Reliable, High-Performance DMD Insulation Paper for Your Transformer Projects?

Contact us now to receive free samples and professional technical support!

We supply a full range of international-standard DMD insulation materials to ensure long-term, stable operation of your power equipment.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri