What Advantages Does Aramid Insulation Paper Have Compared With Other Insulation Materials?

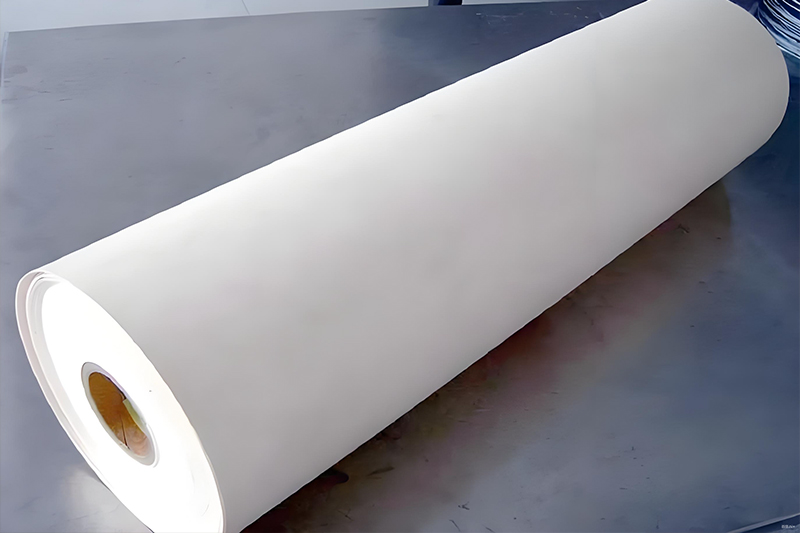

In the field of electrical insulation, material selection directly affects the safety, efficiency, and service life of equipment. Aramid insulation paper (such as Nomex®) has become widely used in recent years as a high-performance synthetic insulation material. Compared with traditional insulation materials such as cellulose paper, mica products, and fiberglass, what unique advantages does it offer? This article analyzes the properties of aramid insulation paper and explains why it is preferred in harsh environments involving high temperatures and strong mechanical stress.

Aramid insulation paper is made from aramid fibers and is classified as a high-performance electrical insulation material. Aramid fibers are synthetic fibers known for high strength, high modulus, and excellent thermal stability, offering outstanding electrical and mechanical performance. Compared with traditional cellulose-based insulation papers, aramid insulation paper provides significantly higher dielectric strength and superior temperature resistance. Its insulation strength can reach 2–3 times that of conventional paper, and it can operate for long periods in high-temperature environments without losing insulating performance.

In addition, aramid insulation paper exhibits low dielectric loss and low dielectric constant. Dielectric loss refers to the energy lost in an insulating material under an electric field, while the dielectric constant indicates the material’s response to that electric field. Due to its unique molecular structure and composition, aramid insulation paper maintains very low dielectric loss and a stable dielectric constant. This allows it to effectively isolate voltage between circuits in electrical equipment, reducing current leakage and minimizing energy loss.

Furthermore, aramid insulation paper features high mechanical strength and excellent abrasion resistance. Traditional cellulose insulation materials tend to perform poorly in mechanical strength and wear resistance, while aramid insulation paper—reinforced with high-strength aramid fibers—offers significantly improved durability. This enables it to better protect internal circuits and components during equipment operation, making it less prone to damage even under long-term mechanical stress.

In addition, aramid insulation paper offers excellent chemical resistance and corrosion resistance. Traditional cellulose-based insulation materials tend to swell, soften, and lose insulating properties when exposed to chemicals or corrosive media. Due to its stable chemical structure and the inherent chemical resistance of aramid fibers, aramid insulation paper performs far better in harsh environments. It is suitable for chemically demanding applications such as chemical plants, electroplating equipment, and other corrosive working conditions.

Finally, aramid insulation paper has a long service life and low maintenance cost. Traditional cellulose insulation materials tend to age, degrade, and lose insulation performance after a period of use, requiring frequent replacement and maintenance. Aramid insulation paper, with its superior insulation stability and durability, significantly reduces maintenance workload and cost while improving equipment reliability and operational stability.

Comparison Between Aramid Paper and Other Insulation Materials

Mica:

Excellent temperature resistance but poor flexibility. It typically requires adhesives to form usable insulation layers, which may affect performance.

Fiberglass:

It can withstand high temperatures, but its dielectric properties depend heavily on the resin system. It tends to degrade in humid environments.

Aramid Paper:

It combines high strength, thermal resistance, and outstanding electrical insulation performance. It can be used directly without additional treatment.

Core Application Scenarios

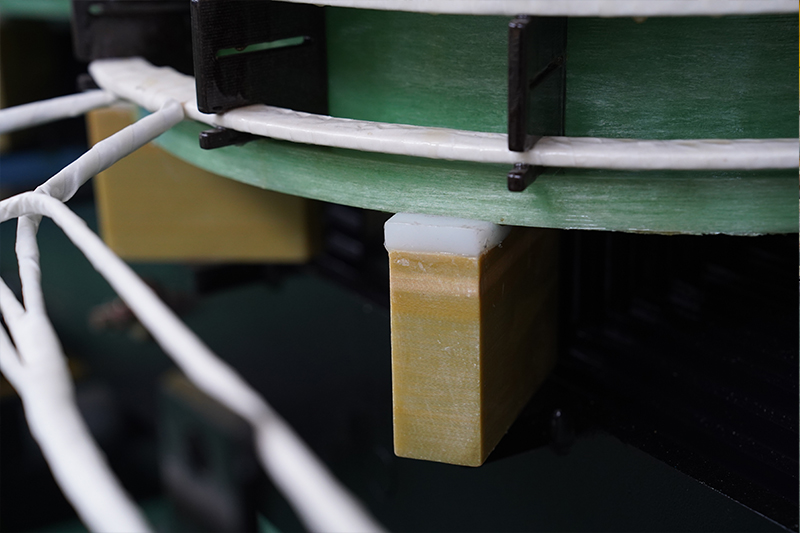

1. Dry-Type Transformers

High-voltage dry-type transformers use aramid insulation paper as the insulation layer between windings and core. It can operate stably for long periods in environments ≥200°C, reducing no-load loss and extending service life.

2. Generators and Electric Motors

High-speed and high-power motor windings benefit from aramid insulation paper due to its excellent durability. It enhances insulation reliability and reduces damage caused by mechanical vibration.

3. High-Frequency Electronic Equipment

Aramid insulation paper features excellent heat resistance and low dielectric loss. When used in high-frequency transformers and inverters, it enables stable operation under high-frequency and high-temperature conditions, improving efficiency and reducing energy consumption.

4. High-Voltage Capacitors and Switchgear

Aramid insulation paper has outstanding dielectric properties that allow it to withstand strong electric fields inside high-voltage equipment. This significantly enhances insulation reliability and operational safety.

Selection Guide: Is Aramid Paper Suitable for Your Project?

Although aramid insulation paper is more expensive than traditional materials, it is recommended in the following situations:

♦ The equipment must operate continuously at temperatures above 150°C.

♦ The operating environment involves mechanical vibration, chemical corrosion, or high humidity.

♦ The project requires lightweight or compact design, such as in new energy equipment.

Aramid insulation paper offers irreplaceable advantages due to its high-temperature resistance, superior strength, excellent electrical properties, and outstanding environmental adaptability. Whether for dry-type transformers, high-speed motors, high-frequency electronics, or high-voltage switchgear, aramid insulation paper helps ensure safe, stable, and efficient equipment operation.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri