Insulation Paper Production Cost and Profit Analysis: Industry Trends and Development Prospects

Against the backdrop of global energy restructuring and power infrastructure upgrades, insulation paper, as a key material in the power electronics industry chain, is attracting increasing attention for its production costs and profit structure. This article systematically analyzes the cost structure, profit-influencing factors, and industry competition landscape of insulation paper production, and offers a perspective on future development trends, providing strategic insights for industry participants. With the advancement of the "dual carbon" goals and the rapid development of the new energy industry, the insulation paper industry is facing both new growth opportunities and the dual challenges of cost control and technological innovation.

1. Current Market Situation of the Insulation Paper Industry

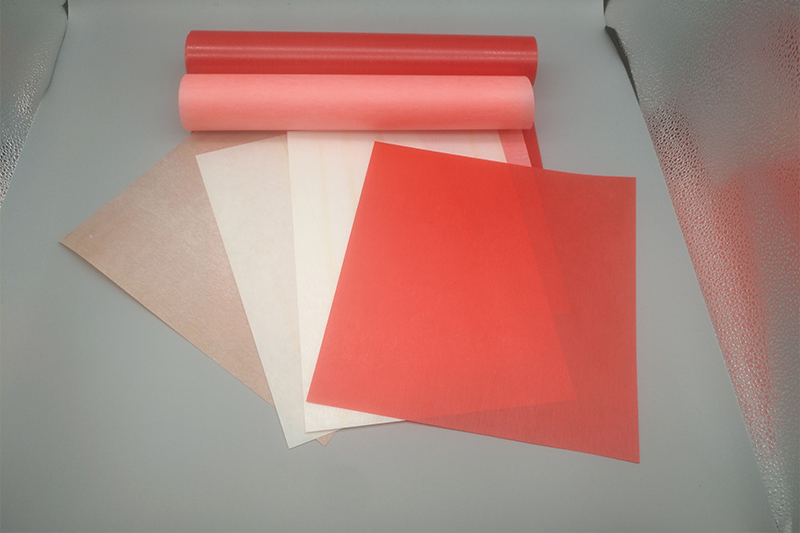

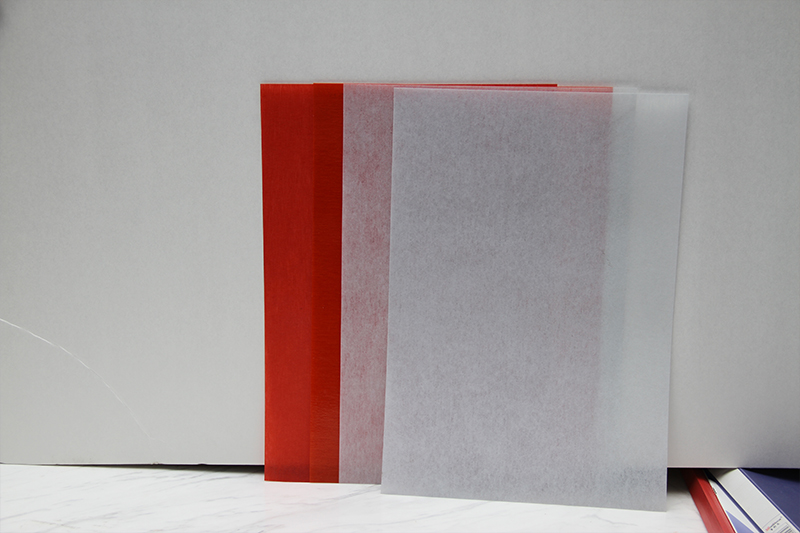

Insulation paper is a fundamental material in the power electronics industry, widely used in the manufacture of products such as transformers, capacitors, and motors. In recent years, with the rapid development of the power electronics industry, market demand for insulation paper has continued to rise. However, competition in the industry has also intensified, with price wars increasing among companies and profit margins significantly compressed.

2. Cost Structure of Insulation Paper Production

The production costs of insulation paper primarily include raw material costs, labor costs, equipment depreciation, and maintenance expenses. Raw material costs are a key factor affecting profits. Due to the significant volatility of raw material prices, companies need to closely monitor market changes and formulate rational procurement plans to control procurement costs. At the same time, improving production efficiency and reducing labor costs are also important ways to achieve cost reduction and efficiency improvement.

3. Strategies for Improving Profitability in Insulation Paper Production

Optimize Product Structure: Develop and produce insulation paper products with a variety of specifications and performance characteristics based on diverse market demands, enhancing product added value and market competitiveness.

Improve Production Efficiency: Improve production efficiency and reduce unit product costs through improved production processes, the introduction of advanced equipment, and enhanced employee skills training.

Strengthen Quality Control: Establish a comprehensive quality management system to ensure stable and reliable product quality and improve customer satisfaction and loyalty.

Expand Sales Channels: Actively explore domestic and international markets, expand sales networks, and increase market share and sales.

4. Profitability Outlook for Insulation Paper Production

With the continued development of the power electronics industry, market demand for insulation paper is expected to continue to grow. At the same time, technological advancement and industrial upgrading will drive continuous improvements in the performance and quality of insulation paper products, creating greater profit margins for companies. However, companies still need to closely monitor market dynamics and technological trends, continuously optimize production and operational strategies, and respond to market competition and changes in the external environment.

The sustainable development of the insulation paper industry relies on companies' meticulous cost management, sustained investment in technological innovation, and rapid response to market changes. Amidst the broader industry trends toward green, low-carbon, and intelligent transformation, insulation paper manufacturers should actively develop high-performance, environmentally friendly products and improve profitability through differentiated competition. In the future, as global demand for power equipment upgrades and renovations grows and emerging application scenarios expand, companies with technological advantages and economies of scale are expected to take a leading position in industry consolidation and achieve high-quality growth.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen