Top DMD Insulation Paper Manufacturers: How to Choose Reliable Suppliers

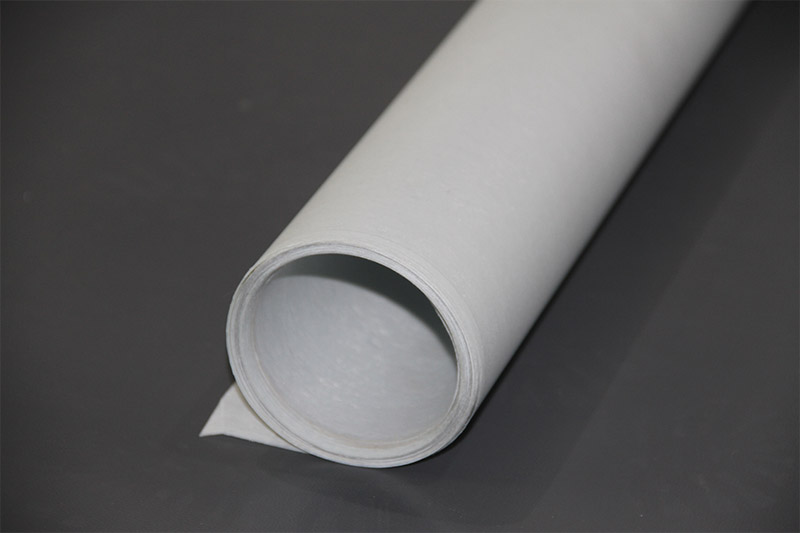

In electrical equipment manufacturing, choosing the right DMD insulation material is crucial—it directly impacts the performance, service life, and safety of motors, transformers, generators, and coils. With so many DMD insulation paper manufacturers on the market, how can you choose a truly reliable, top-tier supplier?

This not only impacts product quality but also determines the stability of your supply chain and the market competitiveness of your final product. This guide will provide you with a systematic evaluation framework to help you make an informed choice.

Why choose a reliable DMD insulation paper supplier?

As a critical insulation material, DMD insulation paper performs four core functions:

Electrical insulation: Withstands high electric field strength without breakdown.

Mechanical strength: Provides excellent support and toughness, resists tearing.

Thermal stability: Maintains performance at high temperatures and resists degradation.

Chemical resistance: Resists grease, solvents, and corrosive chemicals.

Choosing an unreliable supplier may result in inconsistent or inferior products, leading to premature product failures, recalls, and even safety incidents. This ultimately damages your brand reputation and results in significant financial losses.

Seven Key Criteria for Top DMD Insulation Paper Manufacturers

1. Product Quality and Certifications

This is the primary factor in evaluating suppliers.

Standard Compliance: Ensure the product meets International Electrotechnical Commission (IEC) and National Electrical Manufacturers Association (NEMA) standards, as well as your country's specific standards (such as China's GB standard).

Material Composition: Understand the raw material sources of the polyester film and polyester felt used in the product. Top manufacturers typically use well-known brands such as DuPont™ Mylar®.

Third-Party Certification: Prioritize factories certified to ISO 9001 quality management systems. If necessary, also check for UL certification and SGS reports, which provide concrete evidence of product quality.

2. Technical Capabilities and R&D Levels

Top manufacturers don't just manufacture products, and they also provide technical assistance.

Customization Capabilities: If you require a product with a specific thickness, weight, coating, or pre-impregnation treatment, a reliable supplier should be able to provide a customized solution tailored to your application (e.g., Class H or Class F insulation).

Technical Support: Is there a dedicated team to answer any questions you may have? Can you provide detailed technical data sheets (TDS) and material safety data sheets (MSDS)?

R&D investment: Understanding the effort they devote to new product development can provide insights into a company's future innovation capabilities.

3. Production Scale and Manufacturing Capacity

This directly determines whether the supplier can meet your needs stably and promptly.

· Confirm that their production capacity is sufficient to handle your large-volume orders and keep pace with future demand growth to avoid supply chain disruptions.

· Advanced production lines, sophisticated coating, and laminating technologies are essential to ensuring uniform product thickness and consistent performance.

· Inquire about their quality control processes to see how they ensure consistent performance from roll to roll and batch to batch.

4. Market Reputation and Customer References

Past performance can provide an indication of future service quality.

Industry Experience: How long have you been in the DMD insulation paper industry? Which notable clients have you served?

Request successful customer case studies, especially those related to your industry. Positive customer feedback is very convincing.

Industry Status: Are they members of industry associations? Do they participate in major industry trade shows?

5. Testing and Quality Control Processes

Reliable suppliers will proactively share their quality control systems with you.

In-house laboratories: Top manufacturers typically have well-equipped in-house laboratories, testing key indicators like breakdown voltage, thickness, and tensile strength before each batch of product leaves the factory.

Traceability: Does the product have a traceable batch number? This is crucial for tracing and addressing quality issues.

On-site audits: Are they willing to have you visit their factory? This is the most direct way to verify their actual production practices and quality control standards.

6. Supply Chain Stability and Delivery Capabilities

In a globalized market, a stable supply chain is crucial for businesses.

· Is the supply of raw materials stable? Are there ways to mitigate shortages?

· For standard products, is there sufficient inventory to ensure prompt delivery?

· Can domestic and international logistics be efficiently handled to ensure safe and timely delivery of goods?

7. Price and Value

This is the last consideration, but not the least—the lowest price often doesn't guarantee the best results.

Value for money: Consider a combination of price and factors such as quality, service, and technical support. To avoid equipment downtime and costly repairs, it's often more cost-effective to spend a little more on high-quality insulation materials.

Transparency: Is the pricing structure clear? Are there any hidden charges?

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen