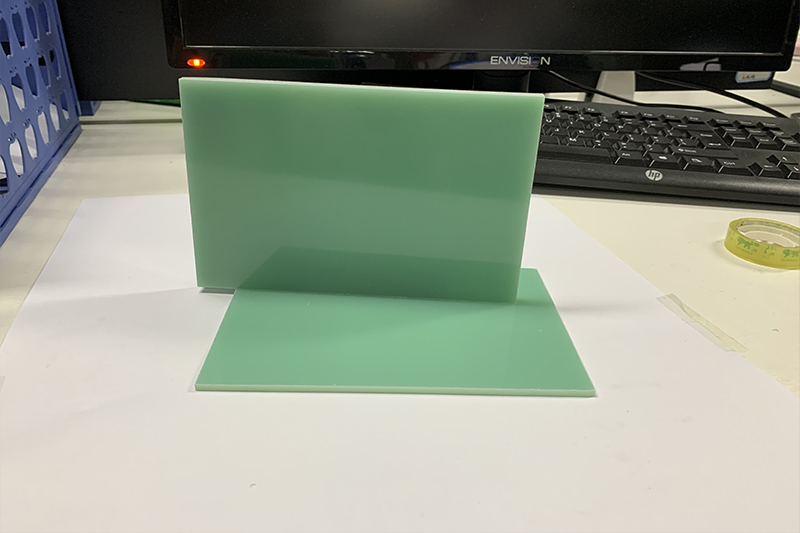

Halogen Free G10 Epoxy Sheet

G10 epoxy sheet, a member of the "glass fiber reinforced epoxy laminate" category, is a composite material made of glass fiber cloth reinforced with epoxy resin, then cured and laminated under high temperature and high pressure.

1. Structural Analysis

The combination of glass fiber and epoxy resin is similar to the relationship between steel and concrete in construction:

Glass fiber: Provides the material with extremely high mechanical strength and dimensional stability, serving as the core support structure.

Epoxy resin: Primarily acts as a bonding agent, while also imparting excellent electrical insulation, chemical resistance, and adhesion properties.

2. Core Characteristics

Excellent Mechanical Properties: Exceptionally strong and rigid, it resists deformation during use.

Stable Insulation: Excellent electrical insulation, maintaining good insulation even in humid environments.

Excellent Heat Resistance: Operating temperatures typically exceed 130°C, making it suitable for medium to high temperature applications.

Strong Chemical Resistance: Resists corrosion from most solvents and chemicals, extending its applicability.

Easy processing: Supports various machining methods such as drilling, cutting, milling, and stamping, which facilitates subsequent forming.

What is halogen-free?

"Halogen-free" is a key and mandatory environmental requirement in the current electronics industry. Its core meaning and background are as follows:

1. What are halogens?

Halogens refer to the four elements in the periodic table: fluorine (F), chlorine (Cl), bromine (Br), and iodine (I). In traditional G10/FR-4 materials, compounds containing bromine (Br) and chlorine (Cl), such as polybrominated diphenyl ethers (PBDEs) and polybrominated biphenyls (PBBs), are often added as flame retardants to achieve flame retardancy (preventing circuit board fires).

2. Why is halogen-free required?

Environmental and health protection: Halogen-containing flame retardants, when incompletely burned, can produce toxic and carcinogenic substances such as dioxins and furans, posing serious risks to human health and the ecological environment.

Regulatory constraints: International environmental regulations, such as the EU RoHS Directive (Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic Equipment), have explicitly restricted the use of some halogen-containing flame retardants.

Recycling Requirements: Halogen-containing materials are more difficult to handle and recycle after disposal, and are prone to generating hazardous substances during the process, which is inconsistent with the concept of green recycling.

3. Halogen-Free Industry Standards

According to IPC-4101D, the industry-recognized "halogen-free" content limits are:

Chlorine (Cl) content: ≤ 900 ppm (i.e., 0.09%)

Bromine (Br) content: ≤ 900 ppm (i.e., 0.09%)

Total halogen (Cl + Br) content: ≤ 1500 ppm (i.e., 0.15%)

Definition and Features of Halogen-Free G10 Epoxy Sheet

Combining G10 epoxy sheet with halogen-free requirements, halogen-free G10 epoxy sheet refers to laminates made from a specially formulated halogen-free epoxy resin system bonded to glass fiber cloth and cured under high temperature and pressure. It retains the excellent physical and mechanical properties of traditional G10 material while meeting the strict halogen content limits imposed by environmental regulations.

Its core features can be summarized in three points:

Environmental safety: Compliant with international environmental directives such as RoHS, the material does not produce toxic substances such as dioxins when incinerated, making it more environmentally and human-friendly.

Green flame retardancy: Flame retardancy is achieved through halogen-free flame retardants such as phosphorus-based, nitrogen-based, and metal hydroxides (such as aluminum hydroxide). However, these alternatives may present challenges in cost, processability, or certain performance characteristics (such as moisture resistance and CTI), which require formulation optimization.

Performance matching: Key performance indicators such as mechanical strength, insulation, and heat resistance are essentially on par with halogen-containing G10/FR-4, making it a direct environmentally friendly alternative to traditional materials.

Leveraging its core advantages of "environmental protection + high performance," halogen-free G10 epoxy sheet is expanding beyond the traditional electronic insulation field into emerging markets such as new energy, 5G, and rail transit. For companies, choosing this sustainable material is not only a guarantee of product quality but also a key strategic move for future market development.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen