Ten Core Reasons to Choose Oil-Immersed Transformers

In modern power transmission and distribution systems, transformers are the backbone of reliable electricity delivery. Their performance, cost-effectiveness, and durability directly determine the stability of power networks. Among all types, the oil-immersed transformer has earned a leading role due to decades of refinement, proven reliability, and excellent economic performance. Below, we analyze ten core reasons why oil-immersed transformers are the preferred solution for medium- and high-voltage systems, large-capacity projects, and industrial power supply.

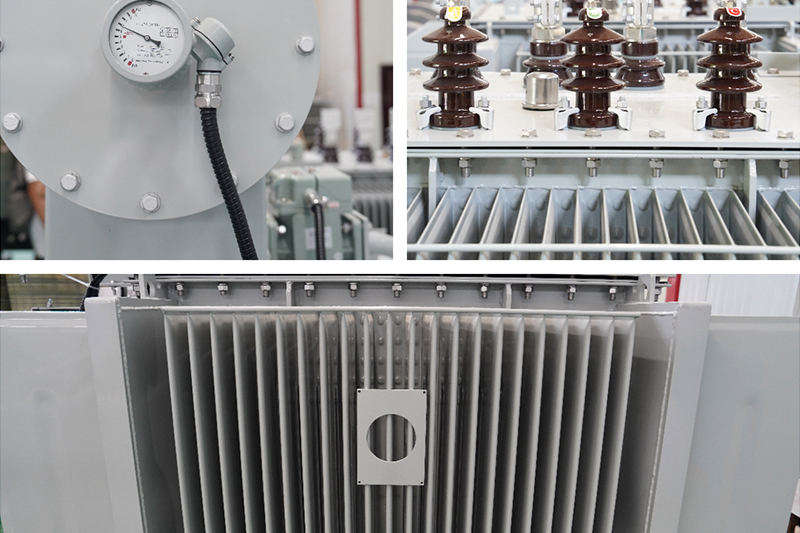

1. Excellent Insulation and Cooling Performance

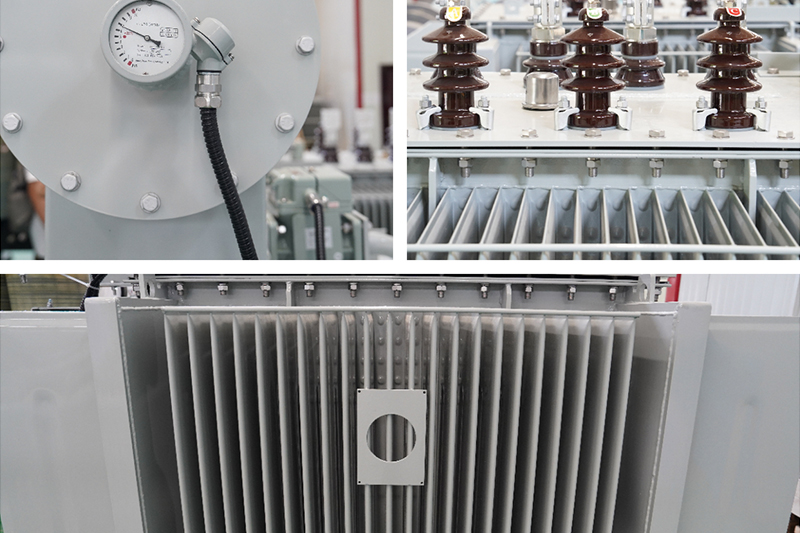

Transformer oil offers superior insulation compared to air, effectively preventing internal short circuits. It also functions as a highly efficient cooling medium, transferring heat from the windings and core to radiators through convection. This provides exceptional heat dissipation, enabling the transformer to handle heavy loads and overload conditions with stability.

2. Strong Short-Term Overload Capability

The high heat capacity of transformer oil slows down temperature rise, allowing oil-immersed transformers to endure temporary overloads without immediate damage. This resilience is critical during peak demand or emergency scenarios, ensuring continuous operation of the power grid.

3. High Reliability and Long Service Life

Oil-immersed transformer technology is mature, supported by decades of design and operational experience. With proper maintenance, their service life typically reaches 20–30 years, and in many cases longer. This makes them one of the most stable and dependable assets in power systems.

4. Efficient Fault Detection and Diagnostics

Modern online monitoring tools such as Dissolved Gas Analysis (DGA) make it possible to detect faults at an early stage. By analyzing gas concentrations dissolved in oil, potential issues like overheating or partial discharge can be identified early. This supports predictive maintenance, reduces unplanned downtime, and minimizes risk of catastrophic failures.

5. Robust Structure and Strong Environmental Resistance

The sealed oil tank isolates windings and the core from external contaminants such as moisture, dust, chemicals, and salt fog. It also prevents intrusion by mold or small animals, allowing reliable outdoor installation in harsh environments including coastal, desert, and industrial zones.

6. Excellent Arc-Extinguishing Capability

In the event of an internal arc fault, transformer oil decomposes rapidly to release gas that compresses the arc channel. Combined with the oil’s cooling effect, this extinguishes the arc quickly, limiting fault escalation and enhancing operational safety.

7. Superior Cost-Effectiveness and Economic Advantage

For high-voltage applications and capacities above 2000 kVA, oil-immersed transformers cost significantly less to manufacture compared with dry-type transformers of equivalent rating. This lower upfront investment makes them the economical choice for utilities, substations, and industrial projects requiring large-scale power capacity.

8. Compact Size and Higher Power Density

Due to the excellent insulation and cooling properties of oil, oil-immersed transformers are smaller and lighter than dry-type transformers with similar ratings. This higher power density reduces installation space requirements, especially valuable in space-constrained substations and industrial facilities.

9. Convenient Maintenance with Controllable Costs

Maintenance of oil-immersed transformers mainly involves oil management—testing, level inspection, and replacing silica gel breathers. These tasks are standardized, infrequent major overhauls are required, and overall costs remain predictable and low. This makes long-term operation cost-effective and manageable.

10. Recyclability and Eco-Friendly Disposal

The main materials—steel, copper, and oil—are recyclable. Although mineral oil has limited biodegradability, established recycling systems ensure safe disposal. Increasingly, eco-friendly ester-based insulating oils with high biodegradability and high flash points are used, reducing environmental impact and fire risk.

The Scientific Logic Behind the Advantages

The advantages of oil-immersed transformers are rooted in their design principles. The oil–paper insulation system resists corona aging better than solid insulation, extending component life. The sealed tank prevents oxygen exposure and reduces mechanical stress, while convective oil cooling is nearly twice as effective as air cooling. These fundamentals ensure outstanding reliability and efficiency.

Limitations and Application Considerations

Despite their strengths, oil-immersed transformers also present challenges, including potential leakage and fire hazards. Therefore, they are generally unsuitable for indoor installation in densely populated spaces such as commercial centers, high-rise office floors, or subway stations, where fire safety is paramount. In such environments, dry-type transformers are a more suitable alternative.

For the majority of high-voltage, large-capacity power systems, oil-immersed transformers remain the most reliable, efficient, and cost-effective choice. Their superior insulation, cooling, robustness, and economic advantages make them indispensable for modern industrial power supply. While dry-type transformers meet niche safety requirements, oil-immersed transformers will continue to dominate large-scale applications and contribute to global power stability.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen