Electrical Paper Pressboard vs. Insulating Paper: Key Differences Explained

In the field of electrical insulation materials, electrical paper pressboard and insulating paper are two core categories. Although they belong to the paper-based insulating material system, there are significant differences between the two in terms of thickness, purpose, production process and performance characteristics. These differences not only determine their different application scenarios in equipment such as motors, transformers, cables, etc., but are also directly related to the insulation reliability, durability and safe operation of electrical equipment. Below we will systematically sort out the main differences between the two from five dimensions.

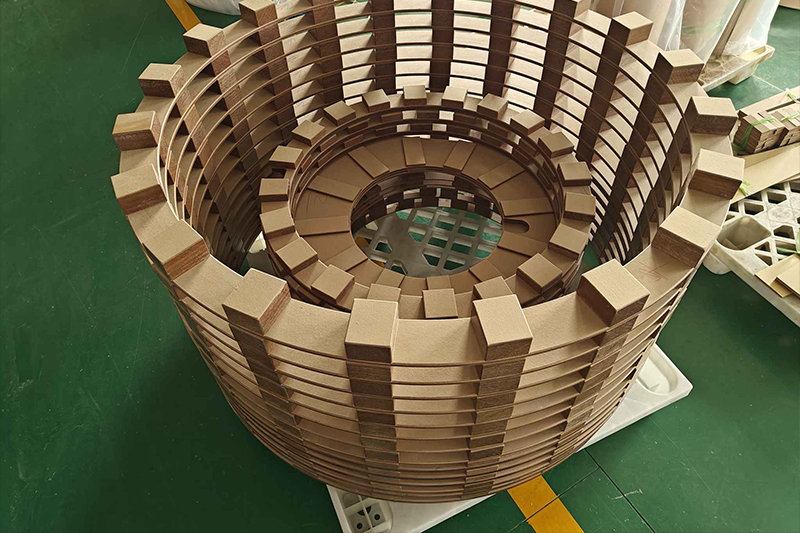

Electrical paper pressboard is an electrical material for motors, electrical appliances, instruments, switch transformers, etc. and their components. It is mainly used to make slots, windings, gaskets, protective layers and other air medium insulation materials. It can also be used as a partition material in transformer oil tanks at a temperature not higher than 90°C.

Insulating paper is a special paper designed for electrical insulation. It has excellent electrical properties, mechanical properties and environmental resistance. It is widely used in electrical equipment such as motors, cables, transformers, etc. to isolate live parts, prevent leakage and short circuits, and ensure the safe operation of equipment. There are many types of insulating paper, such as cable paper, telephone paper, NMN composite paper, etc.

The difference between electrical paper pressboard and insulating paper

1. Thickness and shape

Electrical paper pressboard: Its thickness ranges from 0.1mm to 6.0mm, and it is divided into two forms: flat plate and roll.

Insulating paper: Its thickness ranges from 0.05mm to 0.13mm, mainly thin rolls, and its shape is lighter and thinner.

2. Application fields

Electrical paper pressboard: It is mainly used to manufacture motor slots, windings, gaskets and other structural parts, as well as partition materials in transformer oil tanks, and undertakes mechanical support and basic insulation functions.

Insulating paper: It is directly used in core insulation scenarios such as cable insulation, coil interlayer insulation, telephone line insulation, etc. Some products (such as Nomex paper) also have special functions such as flame retardancy and high temperature resistance.

3. Production process

Electrical paper pressboard: It is formed by wet copying and dehydrated by hot pressing or cold pressing. The electrical paperboard produced by hot pressing has uniform thickness and smooth surface, while the electrical paperboard produced by cold pressing has better flexibility.

Insulating paper: Its production process varies depending on the material. For example, Nomex paper needs to be calendered to improve dielectric strength, and composite insulating paper needs to achieve performance superposition through film composite process.

4. Raw material ratio

Electrical paper pressboard: It is mainly made of unbleached sulfate wood pulp, and cotton pulp (such as 50/50 kapok mixed pulp) can be added to improve bending resistance and oil absorption.

Insulating paper: Its raw materials include plant fibers (wood pulp, cotton pulp), synthetic fibers (polyester, aramid) and film materials (polyester film, polyimide film), and performance is optimized through a composite process.

5. Performance characteristics

Electrical paper pressboard: It highlights mechanical strength and voltage resistance, electrical strength varies with thickness, and heat resistance grade is usually A (105℃) to F (155℃).

Insulating paper: Its performance is significantly differentiated, such as Nomex paper heat resistance grade C (220℃), TFT composite material heat resistance grade N (200℃), and some insulating paper products also have high toughness, high thermal conductivity and other characteristics.

The differences between electrical paperboard and insulating paper in thickness, application field, production process, raw material ratio and performance characteristics are very obvious. It is these differences that make them play an indispensable role in electrical equipment, and jointly provide key insulation guarantee for the stable operation of electrical equipment, meeting the diverse needs of insulating materials in different scenarios.

- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen