Phenolic Paper Sheets in Power Electronics: A Complete Guide from Properties to Practical Use

With the continuous development of power electronics technology, insulating materials are crucial to the safety and stability of equipment operation. As a typical representative of traditional insulating materials, phenolic paper sheet occupies an important position in medium and low voltage power electronics scenarios with its unique physical, chemical and electrical properties. Next, this article will comprehensively analyze the characteristics and application scenarios of phenolic paper sheet, and explore its advantages and limitations in actual use.

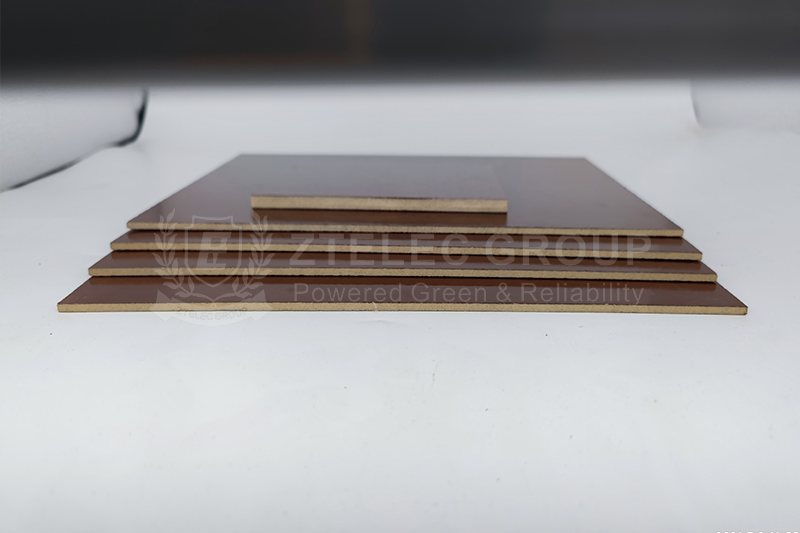

1. Analysis of the characteristics of phenolic paper sheet

Electrical performance

The insulation capacity of phenolic paper sheet is very reliable. In medium and low voltage environments, it can effectively isolate conductive parts and ensure the safe operation of equipment. Its dielectric strength is at a moderate level, so it is very suitable for the use of power frequency and low frequency electronic equipment. However, once in a high-frequency circuit or high-voltage environment, the dielectric loss of phenolic paper sheet will increase, and the risk of partial discharge will increase accordingly, affecting its insulation performance.

Mechanical properties

This material has excellent mechanical strength and rigidity, so it is often used as a support and fixing component for power electronic equipment. However, phenolic paper sheet has poor toughness. It is easy to brittle fracture under complex stress or impact. Therefore, in actual use, it is necessary to take corresponding protective measures in advance according to the specific working conditions.

Thermal properties

Compared with ordinary paper materials, phenolic paper sheet has more advantages in heat resistance and can work stably in a medium temperature range. However, if it is in a high temperature environment for a long time, the aging rate of the material will accelerate, which will lead to a decrease in mechanical strength and insulation performance, and ultimately affect the service life of the equipment.

Chemical stability

Phenolic paper sheet has a certain tolerance to common solvents and oils. However, it is very easy to deteriorate in strong acid, strong alkali or humid environment. Therefore, in actual application, it is necessary to enhance its adaptability in harsh chemical environments by applying protective coatings and other methods.

2.Typical Application Scenarios in the Field of Power Electronics

Transformer insulation system

In transformers, phenolic paper sheet plays a key insulation role. In oil-immersed transformers, it acts as interlayer insulation for coils, effectively suppressing partial discharge and improving the insulation performance and operational reliability of transformers. In dry-type transformers, when phenolic paper sheet is used in conjunction with epoxy resin castings, it can significantly improve the heat resistance level of the insulation system and extend the service life of the equipment.

High-voltage switchgear insulation parts

Phenolic paper sheet is the core material for high-voltage switchgear insulators. The pillar insulators made of it can withstand strong short-circuit current shocks. In actual projects, switchgears using phenolic paper sheet insulators often perform well in lightning overvoltage tests. In addition, in the inflatable cabinet, the synergistic effect of phenolic paper sheet and SF6 gas can also greatly reduce the size of the equipment, so it is suitable for special scenarios with limited space.

Motor insulation parts

In the field of motor manufacturing, phenolic paper sheet is often used to make slot wedges, washers and other structural parts. In high-speed motors, slot wedges made of phenolic paper sheet can resist centrifugal force and ensure the stability of insulation performance. In explosion-proof motors, the flame retardant properties of phenolic paper sheet can reduce the probability of accidents and provide safety protection for motor operation in dangerous environments.

3. Advantages and limitations in practical applications

Advantages

The biggest advantage of phenolic paper sheet is cost-effectiveness. Compared with new materials such as epoxy resin, it can significantly reduce the production cost of power electronic equipment and is particularly suitable for large-scale production. In addition, its processing technology is relatively simple and easy to cut, stamp and form, which facilitates standardized production and effectively improves production efficiency. In addition, in a dry and mild environment, phenolic paper sheet has high reliability and can play an insulating and supporting role for a long time.

Limitations

Phenolic paper sheet has poor weather resistance. Once in a humid or high temperature environment, its performance will decay rapidly, which greatly limits its application in harsh environments. At the same time, due to its poor high-frequency performance, it cannot meet the needs of high-frequency or high-voltage power electronic equipment. In addition, phenolic paper sheet contains substances such as formaldehyde. During production, use and waste disposal, users must strictly follow environmental protection regulations to reduce harm to the environment and human health.

Although phenolic paper sheet has certain limitations, it still occupies an important position in the field of medium and low voltage power electronics due to its cost and process advantages. With the continuous advancement of materials science, it is expected to further broaden its application by improving its weather resistance, high-frequency performance and environmental protection issues through modification technology.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri