A new choice for electrical insulation materials: performance and application of phenolic paper sheet

In the field of electrical engineering, insulation materials are crucial. It is directly related to whether electrical equipment can operate safely and whether the performance is stable. With the development of science and technology, new insulation materials continue to emerge. Among them, phenolic paper sheet has gradually become a new choice for electrical insulation materials with its own advantages.

Performance advantages of phenolic paper sheet

1. High mechanical strength

Phenolic paper sheet is made of electrical insulation paper impregnated with phenolic resin. When it is made, it must go through drying and hot pressing processes, and the final result is a hard plate-shaped insulation material. This unique process gives phenolic paper sheet a relatively high mechanical strength. It can withstand certain external forces and impacts and is not easily damaged. In electrical equipment that needs to withstand mechanical stress, such as insulating structural parts of motors and electrical equipment, the advantages of phenolic paper sheet are very obvious.

2. Excellent electrical insulation performance

Phenolic paper sheet has good electrical insulation performance. At normal temperature, its electrical performance is stable, which can effectively isolate current and reduce the possibility of electrical failure. In addition, it also has a certain arc resistance performance, which can resist arc invasion to a certain extent and protect equipment and personnel safety.

3. Good oil and corrosion resistance

Phenolic paper sheet is impregnated with phenolic resin. Phenolic resin has good oil and corrosion resistance. Therefore, phenolic paper sheet can be used for a long time in environments such as transformer oil. In this environment, its insulation performance and mechanical strength will not be affected. This feature makes it have a wide range of application prospects in electrical equipment such as transformers and switchgears.

4. Excellent processing performance

Phenolic paper sheet is easy to machine. It can be sawed, drilled, turned, and milled, and no cracks or shearing will occur during the processing. For thin products, punching and shearing can also be performed. Such processing performance makes phenolic paper sheet highly flexible and adaptable in the manufacturing process, and can meet the needs of different shapes and sizes.

5. Stable heat resistance

Phenolic paper sheet has excellent heat resistance. Its performance can remain stable within a certain temperature range. Even in a high temperature environment, its electrical insulation performance and mechanical strength are still good. Therefore, it is suitable for electrical equipment and occasions that need to withstand high temperatures.

Application fields of phenolic paper sheet

1. Motor and electrical equipment

Phenolic paper sheet is widely used in motor and electrical equipment. Because of its high mechanical strength and good electrical insulation performance, it is often used as insulating structural parts such as motor armature parts, movable covers, slot wedges, fixed pads, etc. When the motor is running, these parts need to withstand mechanical stress and electrical stress. The performance of phenolic paper sheet can ensure the safe operation and long-term stability of the motor.

2. Power distribution equipment

In power distribution equipment, phenolic paper sheet also plays an important role. It can be used as partitions, linings, terminal boards, phase insulation, bottom partitions, etc. of distribution cabinets. These components provide reliable electrical insulation and mechanical support for power distribution equipment. The oil resistance and corrosion resistance of phenolic paper sheet enable it to be used for a long time in environments such as transformer oil, further expanding its application range in power distribution equipment.

3. Transformer

The transformer is an important equipment in the power system, and its insulation performance is related to the safe operation of the power grid. Phenolic paper sheet has excellent oil resistance and electrical insulation performance and is widely used in transformers. It is often made into insulating structural parts such as insulating gaskets and partitions to ensure the safety and stability of transformer operation.

4. Electronics industry

In the electronics industry, phenolic paper sheet is equally important. It can be used to make PCB test fixtures, clamps and other equipment parts. With good machining performance, it can be processed into different shapes to meet the electronics industry's demand for precision parts and assist in the development and production of electronic products.

Phenolic paper sheet vs Epoxy sheet:

|

Comparison Item |

Phenolic Paper Sheet |

Epoxy Sheet |

|

Base Material |

Insulating paper + Phenolic resin |

Fiberglass cloth + Epoxy resin |

|

Electrical Properties |

Moderate insulation, suitable for medium/low voltage environments |

High insulation, suitable for high voltage/high frequency environments |

|

Mechanical Strength |

Moderate, good rigidity but average toughness |

High, excellent rigidity and toughness |

|

Heat Resistance Class |

Max Class E (120°C) |

Max Class H (180°C) |

|

Cost |

Lower, economical choice |

Higher |

|

Typical Applications |

Insulating structural parts in motors and electrical equipment; it can be used in transformer oil |

High-frequency circuits, PCB substrates, high-reliability insulating components |

|

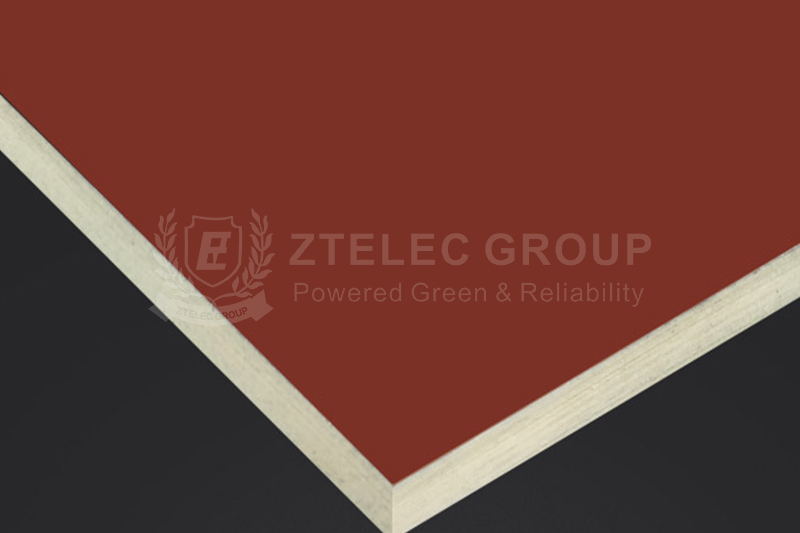

Appearance |

Rough surface, mostly brown-yellow |

Smooth surface, available in various colors |

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri