Insulation materials and insulation technology solutions for the electrical field

Abstract

In the electrical field, choosing the right insulation material is essential to ensure the safety and reliability of the equipment. However, the wide variety of insulation materials and performance parameters are often dizzying, which makes the selection process complicated and difficult. To this end, we offer a one-stop solution to help you easily choose the right insulation material.

Key words: electrical equipment, insulation material, transformer

1.Industry overview

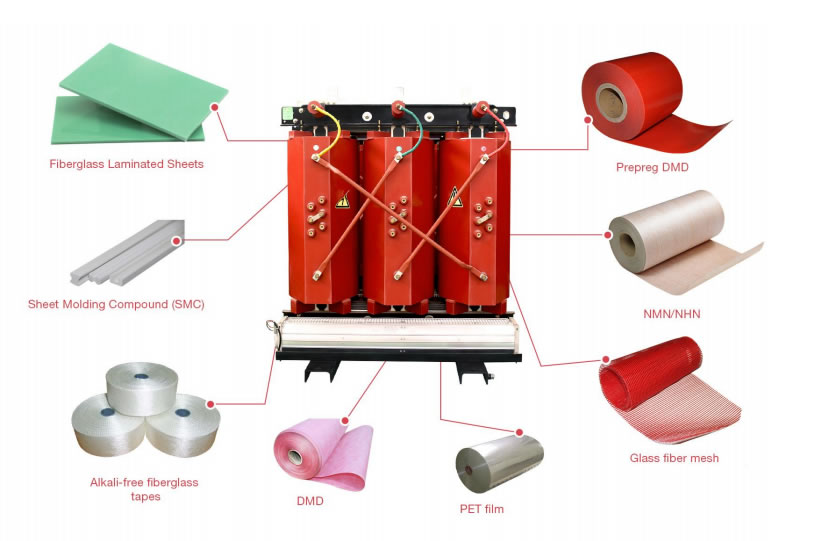

As an important pillar of modern industry, the electrical industry undertakes the key tasks of power production, transmission, distribution, use and power conversion. With the transformation of the global energy structure and the concept of sustainable development, the electrical industry is ushering in unprecedented development opportunities. Especially in the context of global energy structure transformation and sustainable development, the electrical industry has become an important force to promote green and low-carbon development. In order to promote the development of the electrical industry, the quality and quantity of equipment necessary for the electrical industry should be improved. At the same time, the insulation material required in electrical equipment has also increased significantly.2.Introduction of electrical equipment in the electrical field (takedry-typetransformer as an example)

The working principle and structure of the transformer determine that it must use insulation materials. The transformer performs the functions of voltage conversion, impedance conversion, isolation and voltage regulation through the principle of electromagnetic induction. Its internal structure includes iron core, winding and insulation materials. Core materials such as silicon steel sheets are used to improve magnetic conductivity, while the windings are isolated by insulating materials to prevent current leakage and short circuits .

Insulating materials play a vital role in transformers, ensuring their safe operation and long-term stability.

3.Insulating material solutions for use in dry-type transformers in the electrical field

There are many kinds of insulating materials. Which kind of insulation material is low cost and can protect the transformer well, which needs us to carefully screen. After a lot of research and investigation, we put forward the solution of using 3240 epoxy fiber glass laminate in dry-type transformer.

The benefits of this solution are as follows:

1.Resistance to mechanical stress: 3240 epoxy fiber glass laminate has excellent mechanical strength for applications requiring durability and resistance to mechanical stress. 2.Prevent current flow, prevent short circuit: This laminate has high electrical insulation performanceand can prevent current flow, prevent short circuit. 3.Use in high temperature environment: 3240 epoxy fiber glass laminate is resistant to high temperature and can not deform or lose performance in high temperature environment. 4.Use in harsh chemical environments: The laminate is resistant to various chemicals to ensure stability and performance in harsh chemical environments. 5.Customization: This material is easy to cut, drill and form, and can be customized and adapted to the specific requirements of various applications.Characteristics

- Low consumption , energy saving , low noise , no maintenance , no pollution and can be directly installed in the load center ;

- Strong resistance to short circuit , low partial discharge , high reliability ;

- Strong cooling capacity , can be operated under 140% rated load in the condition of forced air cooling ;

- Corrosion resistance , moisture resistance , flame retardant , fireproof , can be operated in high humidity and other harsh environments ;

- Equipped with intelligent temperature controller , which can be monitored and controlled centrally to ensure the reliable

Related to our products are:

| NO. | Product name | Model | Application | Image |

|

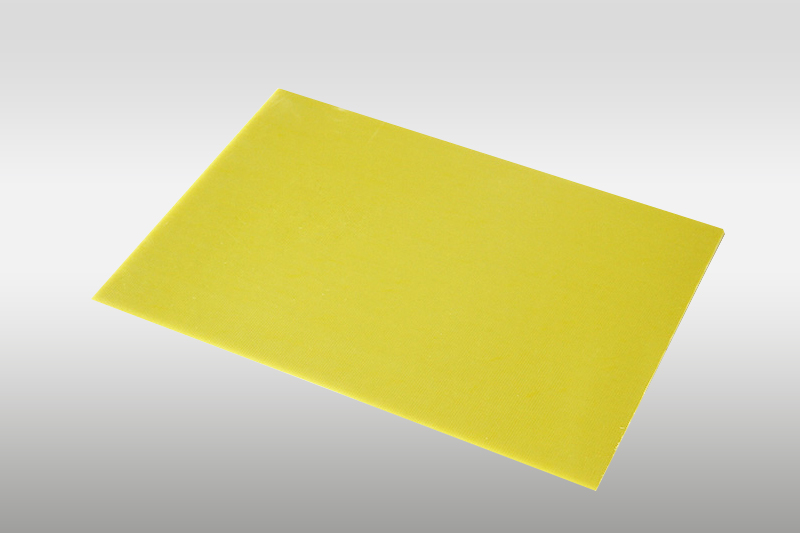

1 |

3240 epoxy fiber glass sheet | EPGC201/202(fr4) /203(G10)/204(fr5) /306(G11)/308 | Insulating structural parts for mechanical, electronic and electrical equipment |

|

|

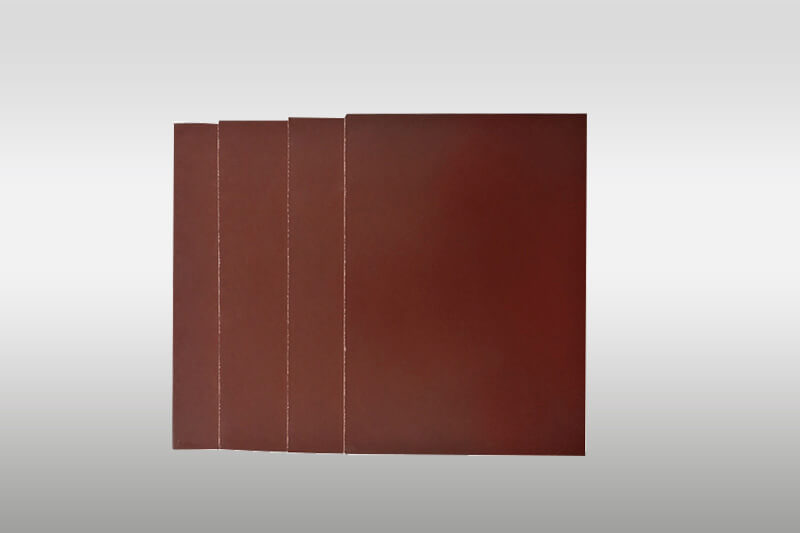

2 |

3021 phenolic laminated paper-base sheet | PFCP 202 | It is used for motors and electrical equipment with high mechanical properties as insulation structural parts. And it can be used in transformer oil |

|

|

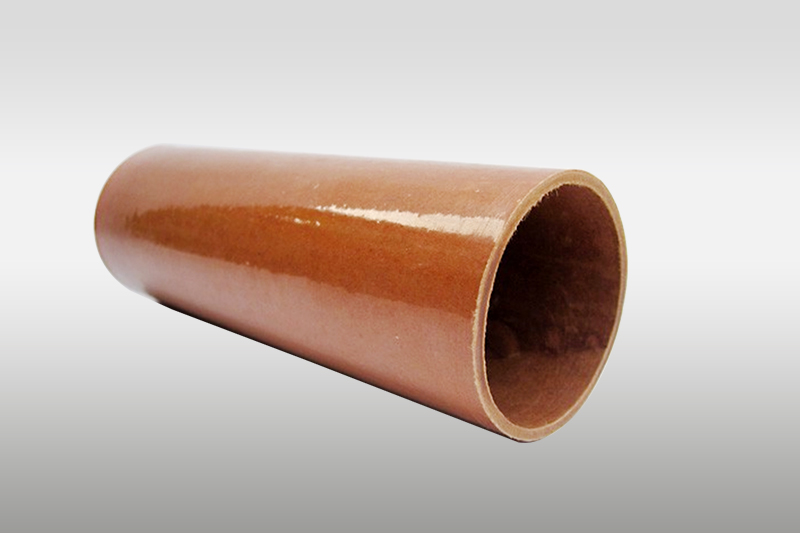

3 |

3520 phenolic paper-base laminated tube | PFCP22A | Used in motors, electrical equipment. And it can also be used in transformer oil. |

|

|

4 |

360 epoxy fiberglass winding tube | EPCF52 | It is used as the main insulator of H class dry transformer, on-load tap-changer, reactor, arrester, SF6 transformer and other products. |

|

|

5 |

3840 epoxy fiber glass cloth laminated rod | EPGC41 | Electrical equipment insulation structure parts, screw parts |

|

4.Summary

With the rapid development of new energy, power system requirements for transformers continue to increase. The market prospects of dry-type transformers are broad because of its good adaptability and continuous innovation of technology. With the use of advanced materials and processes, the efficiency and stability of dry-transformers continue to improve, and the energy loss and failure rate are reduced, which will further enhance their competitiveness in the market . As an essential part of dry- transformers, insulation materials have a broad market prospect.- more+releated article

- 2025-12-13How to Select and Use Phenolic Cloth-base Lami

- 2025-12-13How Much Does Bakelite Sheet Cost? 2025 Price

- 2025-12-13Why are most 3240 epoxy boards yellow?

- 2025-12-13What are the Main Applications of FR4 Epoxy Bo

- 2025-12-13Why Does the Price of Insulating Paperboard Va

- 2025-12-13Heat-Resistant DDP Insulation Paper

- 2025-12-13Comparison of Heat-Resistant DDP Insulating Pa

- 2025-12-13G10 and FR4 Epoxy Boards: Commonly Used for Ge

- 2025-12-13The Price of Heat-Resistant DDP Insulation Pap

- 2025-12-13How to Choose Epoxy Laminate Materials for Gen