Heat resistance grade of phenolic resin insulation board

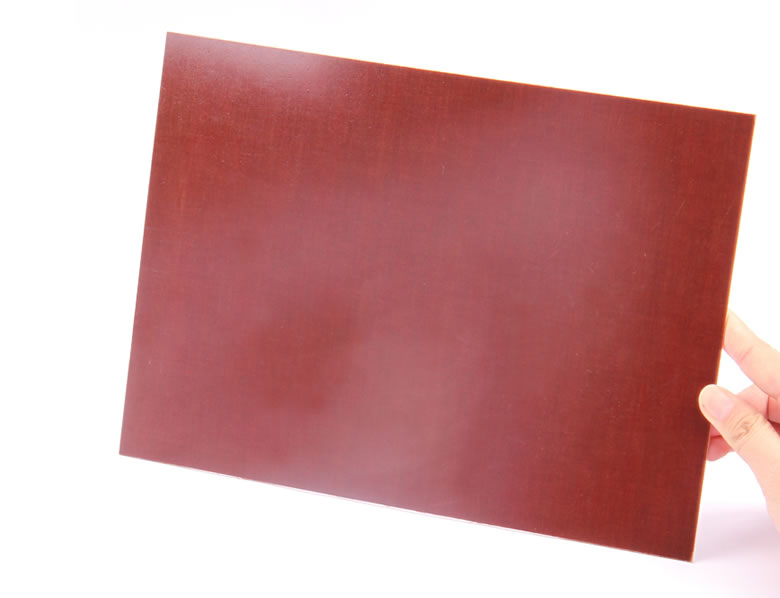

Phenolic resin insulation board is also called phenolic resin laminated sheet,it is a material with excellent insulation and heat resistance, which is widely used in electrical, electronic and mechanical equipment. Its heat resistance grade is an important indicator to measure its heat resistance, which has an important impact on the application range and working environment of the material. The following is a detailed analysis of the heat resistance grade of phenolic resin insulation board:

1. Basic composition and characteristics of phenolic resin insulation board

Phenolic resin insulation board is mainly composed of phenolic resin and reinforcing materials (such as cotton cloth, glass cloth, etc.). Phenolic resin is a thermosetting plastic with high heat resistance and insulation performance. The addition of reinforcing materials improves the mechanical strength and dimensional stability of phenolic resin insulation board. Therefore, phenolic resin insulation board has excellent electrical insulation performance, heat resistance, mechanical properties and corrosion resistance.

2. Heat resistance grade of phenolic resin insulation board

The heat resistance grade of phenolic resin insulation board is usually determined according to its specific manufacturing process and material ratio. Under normal circumstances, the heat resistance grade of phenolic resin insulation board can reach B or F, and some high-grade materials can even reach H.

B-grade temperature resistance: B-grade phenolic resin insulation board can usually work for a long time at a temperature of 130°C, and can withstand a short-term temperature of up to 150°C. This material is suitable for insulating structural parts in general electrical equipment, such as motors, transformers, etc.

F-grade temperature resistance: F-grade phenolic resin insulation board can work for a long time at a temperature of 155°C, and can withstand a short-term temperature of up to 180°C. This material is suitable for electrical equipment with high temperature requirements, such as high-voltage switchgear, transformers, etc.

H-grade temperature resistance: H-grade phenolic resin insulation board is a high-grade insulation material that can work for a long time at a temperature of 180°C, and can withstand a short-term temperature of up to 200°C. This material is suitable for electrical equipment in high-temperature working environments, such as aerospace equipment, high-temperature furnaces, etc.

3. Factors affecting the temperature resistance of phenolic resin insulation board

Resin type: The type and formula of phenolic resin have an important influence on the temperature resistance of insulation board. Different types of phenolic resins have different heat resistance and mechanical properties, so it is necessary to select the appropriate resin type according to the specific application scenario.

Reinforcement material: The type and content of reinforcement material will also affect the temperature resistance grade of phenolic resin insulation board. Commonly used reinforcement materials include cotton cloth, glass cloth, etc. The heat resistance and mechanical strength of these materials are different, which will affect the overall performance of the insulation board.

Manufacturing process: The manufacturing process also has an important influence on the temperature resistance grade of phenolic resin insulation board. By optimizing process parameters such as impregnation, baking and hot pressing, the heat resistance and mechanical strength of the insulation board can be improved.

IV. Application scope of phenolic resin insulation board

Due to its excellent insulation and heat resistance, phenolic resin insulation board is widely used in electrical, electronic and mechanical equipment. It is often used as an insulating structural part of electrical equipment such as motors, transformers, mutual inductors, high-voltage switchgear, and thermal insulation and structural materials in high-temperature working environments.

V. Precautions

When using phenolic resin insulation board, the following points need to be noted:

Correctly select the temperature resistance grade: According to the specific application scenario and equipment requirements, select the appropriate temperature resistance grade of phenolic resin insulation board.

Avoid high temperature exposure: Although phenolic resin insulation board has high heat resistance, long-term high temperature exposure may still cause its performance to deteriorate. Therefore, long-term high temperature exposure should be avoided during use.

Keep dry: Phenolic resin insulation board may cause performance degradation in a humid environment. Therefore, the use environment should be kept dry and avoid contact with water or other liquids.

In summary, the temperature resistance grade of phenolic resin insulation board is an important indicator to measure its heat resistance performance, which has an important impact on the application range and working environment of the material. When selecting and using phenolic resin insulation board, it is necessary to select the appropriate temperature resistance grade and material type according to the specific application scenario and equipment requirements.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri