Talking about the same and differences between epoxy insulating board G10 and fr4

Both G10 and fr4 are developed and applied as insulating materials. Here, we first enumerate what they have in common:

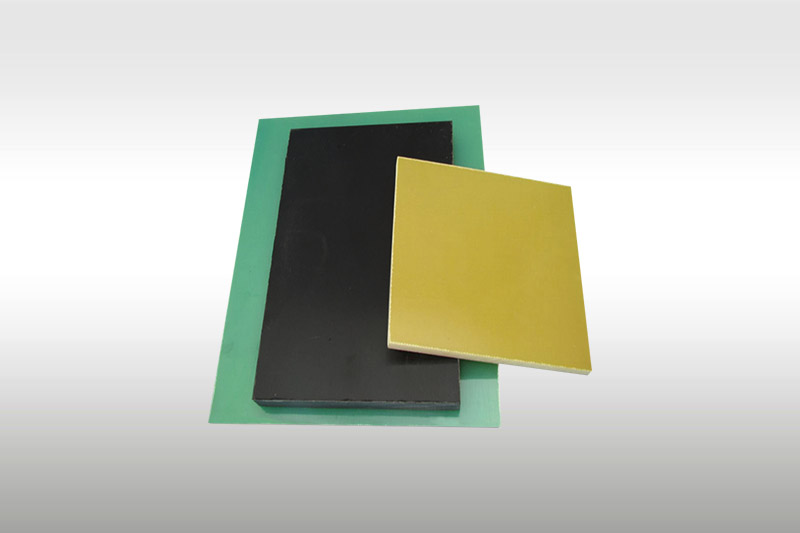

composite materials g10

composite materials fr4

Talking about the same and differences between epoxy insulating board G10 and fr4

1. Essentially the same

The same in essence refers to the same raw materials used to make g10 and fr4. They are all made of electronic-grade glass fiber cloth, and the impregnation used is also the same high temperature epoxy resin, which determines their high temperature resistance and insulation. characteristics.

2. The same production process

They are all formed by the lamination process after impregnating epoxy resin with glass fiber cloth. The unlaminated layer is called pp sheet for short, and the multi-layer glass fiber cloth and resin impregnation and lamination are called laminates after hot pressing. , the number of laminated layers is set according to the needs of users, thus resulting in different thicknesses of laminates. The thicker the thickness, the higher the dielectric constant and the stronger the insulating ability.

3. The same scope of application

Since the materials are similar, the craftsmanship is the same, which determines the similarity of their uses. Because of their stable electrical insulation performance, they are especially suitable for products with high performance electronic insulation requirements, such as FPC reinforcement boards, PCB drilling pads, glass fiber meson potentiometers, carbon film printed glass fiber boards, precision pinion gears, electronic Equipment insulating stay partitions, insulating pads, transformer insulating plates, motor insulating parts, grinding gears, electronic switch insulating plates, etc.

Next, let's talk about the differences between them

1. Different performance

First of all, the heat resistance level of G10 is higher than that of fr4, the temperature resistance of FR-4 is 125-150°, and the strength of G10 is high and the temperature resistance is 160-180°. Therefore, the heat resistance level of fr4 is b, while that of g10 is f. Secondly, the parallel layer breakdown voltage of g10 is also higher than fr4, the parallel layer breakdown voltage of fr4 (in 90 degree transformer special oil) is greater than or equal to 35KV, while g10 can reach 40KV.

2. The details of the process and ingredients are different

We mentioned above that their raw materials and processes are the same, so why are there really two products produced? Then we have to come up with an explanation, the formula of their epoxy resin and curing agent must be slightly different, such as the content of epoxy resin is different, etc.

3. The price of fr4 and g10 is different

The performance of G10 is stronger than that of fr4, which means that the price of g10 is higher than that of fr4. superior.

4. How to distinguish between fr4 and g10

This question is easy to answer. The two are so similar, including the same color after processing, only the performance is different. We only need to inform the required parameters such as the fire resistance level when purchasing the material. It is challenging to find the difference in the appearance.

So much has been introduced, do you know fr4 and g10? To learn more, please follow our website: https://ztelecgroup.com

Welcome to reprint:https://www.ztelecgroup.com/zt-technical-article/496.html

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri