Ten Common Mistakes to Avoid When Purchasing Power Transformers | Selection Guide

Power transformers are critical equipment in power engineering, industrial projects, and new energy systems. Their proper selection directly affects system safety, energy efficiency, and long-term maintenance costs. However, many companies make errors during procurement due to insufficient experience or information gaps, which can lead to transformer failures, higher energy consumption, and project delays.

This guide outlines ten common mistakes in power transformer procurement and provides practical solutions to help engineering teams and procurement personnel make accurate, informed decisions.

1. Ignoring Load Type and Characteristics

Many purchasers focus solely on total power parameters, overlooking load differences such as resistivity, inductance, and nonlinearity.

Correct Selection: Analyze the load type. For nonlinear equipment like frequency converters and UPS systems, K-factor transformers are recommended. Consider starting currents for motor-type loads and reserve sufficient overload capacity for stable startup.2. Inappropriate Capacity Selection

Oversized transformers waste resources and reduce efficiency, while undersized units may overheat and damage core components.

Correct Selection: Accurately calculate peak and average loads with a 15%-25% safety margin. Plan for future expansion without excessive upfront investment.3. Neglecting Energy Efficiency Ratings

Choosing low-efficiency transformers may reduce initial costs but increases long-term energy losses.

Correct Selection: Prioritize high-efficiency transformers that comply with IEC 60076 standards. Calculate Total Cost of Ownership (TCO) over 10 years, including both purchase price and energy losses.4. Insufficient Consideration of Voltage Regulation

Failure to evaluate transformer voltage stability under load changes can impact sensitive equipment.

Correct Selection: Select impedance parameters according to load sensitivity and consider automatic voltage regulation for precision equipment.5. Neglecting Environmental Conditions

Factors like high temperature, humidity, and altitude affect insulation and heat dissipation.

Correct Selection: Choose high-temperature rated insulation in hot areas, adjust capacity for high-altitude locations, and focus on moisture-proof and well-sealed designs in humid environments.

6. Ignoring Insulation Materials and Manufacturing Quality

Focusing only on external parameters while ignoring internal insulation quality and manufacturing processes can reduce transformer reliability and lifespan.

Correct Selection: Evaluate winding insulation materials such as NMN, NHN, or DMD. Review core material properties, winding techniques, and ensure vacuum drying is performed.7. Neglecting Short-Circuit Withstand Capacity

Failure to assess thermal and dynamic stability during short-circuit faults can cause severe damage.

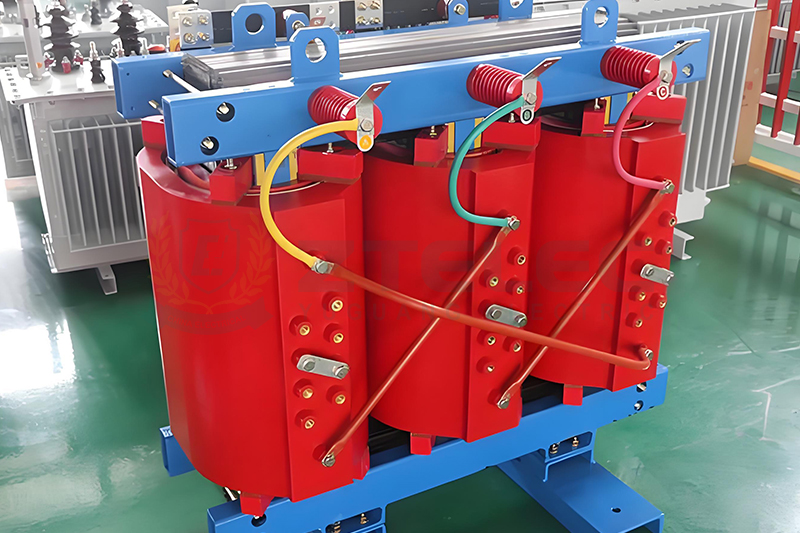

Correct Selection: Request authoritative short-circuit test reports and select transformers rated for the system's maximum short-circuit current.8. Incorrect Choice Between Oil-Immersed and Dry-Type Transformers

Selecting the wrong transformer type for the operating environment reduces adaptability and increases risk.

Correct Selection: Oil-immersed transformers are suitable for outdoor, high-capacity, or high heat-dissipation projects. Dry-type transformers are ideal for indoor, densely populated areas or locations with strict fire safety requirements.9. Incomplete Planning for Installation and Maintenance

Ignoring installation space, ventilation, or maintenance requirements leads to higher operational costs.

Correct Selection: Measure installation dimensions accurately, including handling passages. Prioritize low-maintenance transformers with accessible designs.10. Focusing Only on Initial Purchase Cost

Considering only the upfront price neglects critical factors like long-term energy losses, maintenance, and service life.

Correct Selection: Evaluate energy efficiency parameters such as no-load and load losses. Calculate operating costs over 10-20 years to assess TCO, and prioritize high-efficiency transformers for long-term savings.Power transformers must be tailored to operating conditions and system requirements. Avoiding these ten common mistakes minimizes project risks and improves efficiency, reliability, and ROI. During procurement, communicate closely with professional manufacturers to ensure safe, stable, and long-term operation of your transformers.

- more+releated article

- 2026-01-05Ten Common Mistakes to Avoid When Purchasing P

- 2026-01-05Application of DDP Insulation Paper in Oil-Imm

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board