How Enclosed Dry-Type Transformers Meet Safety Standards

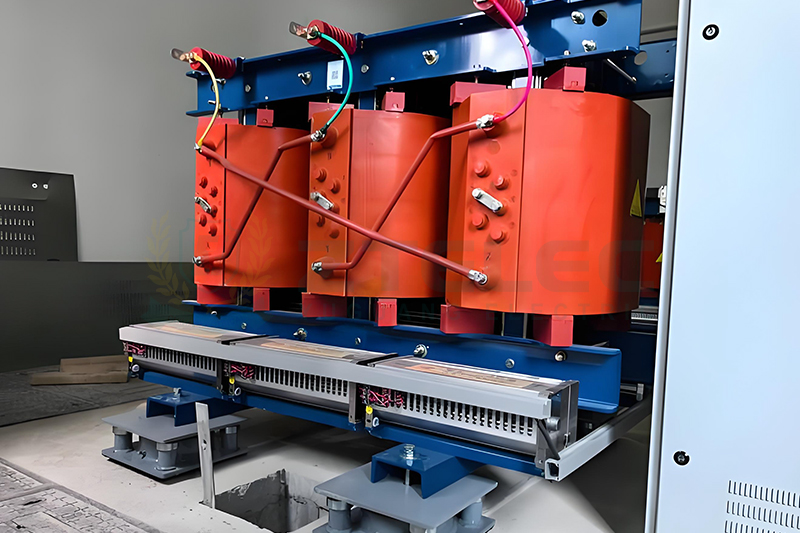

With increasing demands for safety and operational reliability in industrial facilities, commercial buildings, and power systems, enclosed dry-type transformers have emerged as a leading solution. Their oil-free design, fire resistance, environmental compliance, and low maintenance make them ideal for modern applications. Ensuring full compliance with international safety standards is a top priority for engineers and procurement specialists.

International Standards Compliance

Manufacturing and application of enclosed dry-type transformers adhere to key international standards:

| Safety Standard | Key Requirements |

|---|---|

| IEC 60076-11 | Design specifications, temperature rise limits, and electrical testing requirements for dry-type transformers |

| IEC 60076-5 | Short-circuit withstand capability testing |

| UL / CSA Certification | Fire resistance, safety performance, and insulation system certification |

| ISO 9001 / ISO 14001 | Quality management and environmental management systems ensuring manufacturing consistency |

Compliance with these standards ensures reliable safety performance aligned with global technical specifications.

Design Features That Ensure Safety

1. Fire Safety Performance

Oil-free design: Eliminates fire hazards and environmental risks associated with oil leakage, making transformers suitable for indoor and densely populated installations.

Flame-retardant insulation materials: Coils use epoxy resin casting or vacuum pressure impregnation (VPI) combined with flame-retardant varnishes. These materials self-extinguish under high temperatures, meeting UL flame-retardant standards.

K-class fire resistance: Certain models operate under fire exposure for a specified duration, ensuring emergency power supply to critical loads such as fire pumps.

2. Environmental Protection and Personnel Safety

Protection against electric shock: High-strength metal enclosures prevent accidental contact with live components, meeting IP protection standards.

Protection against foreign objects and moisture: The enclosed structure blocks dust, dirt, moisture, and corrosive gases, preventing insulation degradation and short circuits, in line with NEC and IEC requirements.

Pollution resistance: High-standard insulation systems ensure safe operation in industrial environments with dust and surface contamination.

3. Advanced Overheating Protection System

Real-time temperature monitoring: PT100 sensors or thermocouples continuously track winding temperatures.

Integrated alarm and trip functions: Exceeding safe thresholds triggers alarms or shutdowns, preventing insulation damage and complying with UL and IEC overheating protection requirements.

4. Robust Mechanical Structure and Grounding Safety

High-strength enclosure: Ensures mechanical durability and environmental protection for internal components.

Defined grounding system: Standardized grounding terminals safely discharge fault current, protecting personnel and equipment and meeting global electrical safety standards.

5. Electromagnetic Compatibility and Low Noise

Low electromagnetic interference (EMI): Optimized layout and shielding maintain minimal EMI, protecting sensitive electronic equipment and meeting EMC standards.

Low-noise operation: Advanced magnetic circuit and vibration-damping design keep operational noise within regulated limits, supporting workplace health and safety requirements.

Applications in Critical Industries

Enclosed dry-type transformers are widely used in environments requiring high safety performance:

Subways, airports, hospitals, data centers, high-rise buildings, chemical plants, tunnels, solar and wind power stations. Their oil-free design, flame retardancy, environmental compliance, and low noise make them the preferred choice for high-risk applications.

Through advanced protective design, fire-resistant materials, precise temperature control, and international standard compliance, enclosed dry-type transformers provide a safe and reliable solution for modern engineering projects emphasizing fire safety, operational reliability, and environmental performance.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri