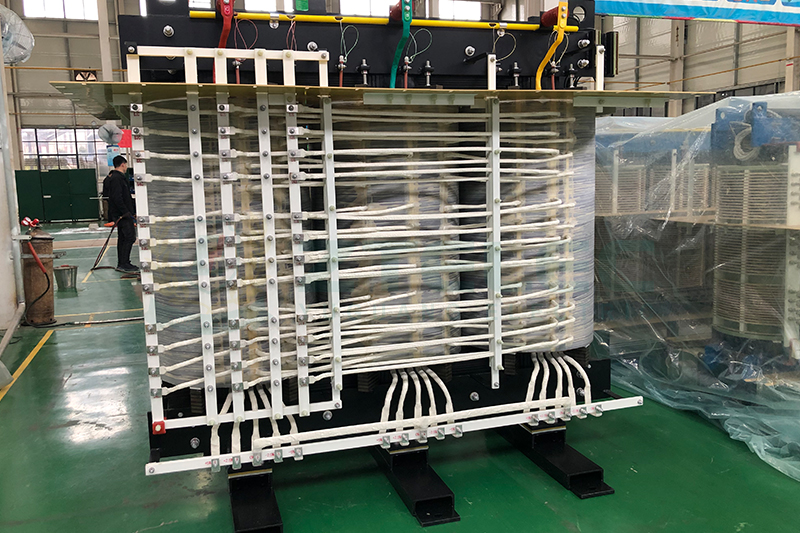

Dry-Type Phase-Shifted Rectifier Transformer: Reducing Harmonics and Improving Power Factor

In modern industrial systems, power electronic equipment such as inverters, medium-frequency furnaces, and DC motor drives heavily rely on rectification to obtain DC power. Traditional rectifier systems, however, generate serious harmonic pollution and low power factor problems. These issues not only raise electricity costs but also threaten the stability of the entire power grid. The ideal solution is the dry-type phase-shifted rectifier transformer.

How the Dry-Type Phase-Shifted Rectifier Transformer Works

This transformer is engineered to provide multi-phase rectified power for medium- and high-voltage inverters. Using extended-delta phase-shifting technology, it forms 9-, 12-, 15-, 18-, 24-, or 27-pulse rectifier systems through multiple secondary windings with different phase-shift angles.

The primary winding connects directly to the high-voltage grid, while the secondary side contains multiple three-phase windings with line voltages phase-shifted by 0°, θ°, …, (60 − θ)°. When n H-bridge units are used per phase, θ = 60°/n, enabling a 6n-pulse rectification system. If the load is balanced, harmonics below 6n±1 on the primary side are effectively removed, significantly improving the power factor without needing additional filters or compensation devices.

This technology is ideal for environments with strict fire safety requirements and fluctuating heavy loads, including offshore platforms, thermal power plants, water treatment facilities, metallurgical processing, chemical production, mining operations, and building material manufacturing.

Why Harmonics and Power Factor Matter

Harmonics cause equipment overheating, increase energy losses, interfere with control systems, and may even trigger resonance with capacitive components of the grid. Low power factor leads to electricity penalties, wasted equipment capacity, and voltage instability. Addressing these issues is crucial for industrial efficiency and safety.

Harmonic Suppression Mechanism

Traditional 6-pulse rectifiers generate harmonics such as 5th, 7th, 11th, and 13th. The dry-type phase-shifted rectifier transformer eliminates these through phase-shifting.

In a 12-pulse system, the secondary windings output one Y-connected and one Δ-connected three-phase group with a 30° phase difference. Each group feeds a 6-pulse rectifier, whose outputs combine to cancel harmonic currents on the primary side. The 5th harmonic from one bridge is 180° out of phase with that from the other, causing cancellation. Similar cancellation occurs for the 7th, 17th, and 19th harmonics.

A 12-pulse system eliminates the 5th and 7th harmonics, an 18-pulse system removes the 5th, 7th, 11th, and 13th, and higher-pulse configurations eliminate even more harmonics. The higher the pulse number, the closer the input current becomes to an ideal sine wave.

Frequently Asked Questions

Q1: How does a dry-type phase-shifted rectifier transformer differ from a traditional transformer with filters?

A traditional transformer with filters provides passive harmonic mitigation and may cause resonance. A phase-shifted transformer actively eliminates harmonics at the source without the risk of resonance, offering more stable performance.

Q2: How should I choose the number of pulses?

This depends on load characteristics and the required harmonic standards. A 12-pulse system is suitable for most applications, while 18-pulse or 24-pulse systems are preferred for strict harmonic environments such as data centers or precision manufacturing.

Q3: What is the return on investment?

Although the initial cost is higher than a standard transformer, companies usually recover the investment within 1–3 years through reduced electricity penalties, lower line losses, and increased equipment lifespan.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri