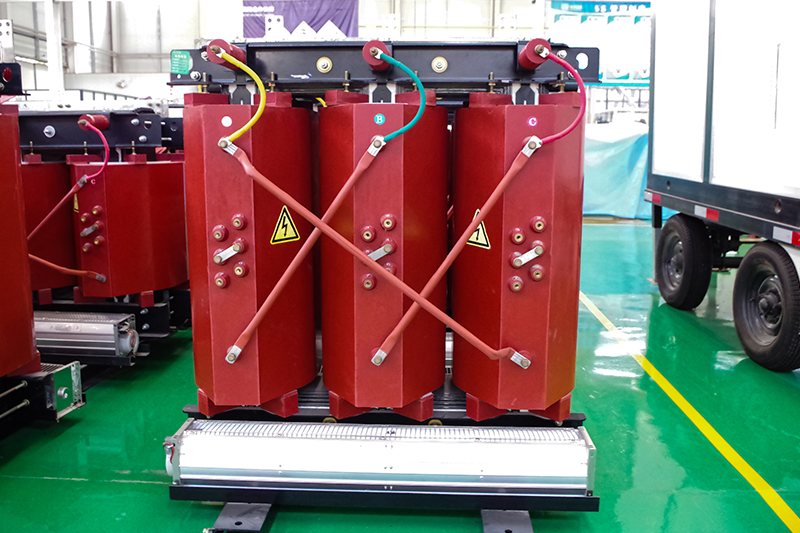

2500kVA 11kV Resin Dry-Type Transformer | 15% Energy Saving

The 2500kVA 11kV resin dry-type transformer is a core power distribution device designed with epoxy resin vacuum-cast insulation technology. It ensures oil-free, fire-resistant, and explosion-proof operation while requiring no routine maintenance. This makes it particularly suitable for indoor distribution facilities, densely populated areas, and industrial environments with strict energy efficiency and safety standards.

Energy-Saving Technology Principle

Material Optimization: The transformer uses high-permeability silicon steel laminations to reduce hysteresis and eddy current losses. High-purity copper conductors minimize winding resistance and resistive losses during load operation.

Structural Design Innovation: Its low-loss core structure with precision jointing reduces flux leakage, while optimized high and low voltage winding layouts minimize stray losses. An intelligent cooling system with composite air ducts enhances heat dissipation for stable high-load operation.

Precision Manufacturing: Vacuum Pressure Impregnation (VPI) ensures excellent insulation and reduced partial discharge. CNC precision winding guarantees uniform insulation and minimized parasitic losses, enhancing durability and efficiency.

Application Scenarios

Data Centers: Enhances PUE by reducing transformer energy losses, ensuring reliable 24/7 power supply and lowering long-term operational costs.

Rail Transit: Delivers high reliability for traction substations, reducing long-term power consumption and ensuring stable operation under frequent load fluctuations.

New Energy Power Stations: Boosts power conversion efficiency in photovoltaic and wind power systems, minimizing losses during transmission and accelerating ROI.

High-End Manufacturing: Provides stable voltage for precision equipment, reduces factory power consumption, and supports green, low-carbon development goals.

Selection, Operation, and Maintenance Guide

Energy Efficiency Verification: Always request third-party test reports to confirm no-load and load losses meet Class-I energy efficiency standards. Prioritize certified products with CQC or China Energy Efficiency Class-I labels.

Load Demand Matching: Evaluate actual load rates to avoid efficiency loss under light-load conditions. For fluctuating loads, use an on-load tap changer (OLTC) to maintain efficiency through dynamic voltage regulation.

Installation & Maintenance: Ensure good ventilation, install forced cooling if needed, and use intelligent monitoring systems with temperature sensors. Regularly test winding resistance, insulation, dielectric loss, and partial discharge. For long-term storage, energize periodically to prevent moisture damage.

Why Choose a 2500kVA 11kV Resin Dry-Type Transformer?

This transformer achieves up to 15% energy savings through optimized materials, innovative structure, and precision engineering. It provides unmatched safety with fireproof, explosion-proof, and oil-free features. Ideal for mission-critical facilities like data centers, rail transit systems, and renewable energy plants, it ensures lifecycle energy efficiency, operational safety, and sustainable cost savings for users.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri