How to Identify Transformer Windings – Practical Guide for Oil-Immersed and Dry-Type Transformers

Accurately identifying transformer windings is essential during inspection, maintenance, and commissioning for both oil-immersed transformers and dry-type transformers. This ensures correct electrical connections, prevents operational faults, and improves maintenance efficiency. Below, we detail multiple transformer winding identification methods, including appearance and structure analysis, insulation material checking, label interpretation, electrical testing, and connection method recognition.

1. Identification by Appearance and Structure

The physical arrangement, insulation materials, and lead wire markings of a transformer’s windings provide intuitive identification clues.

1.1 Winding Arrangement Observation

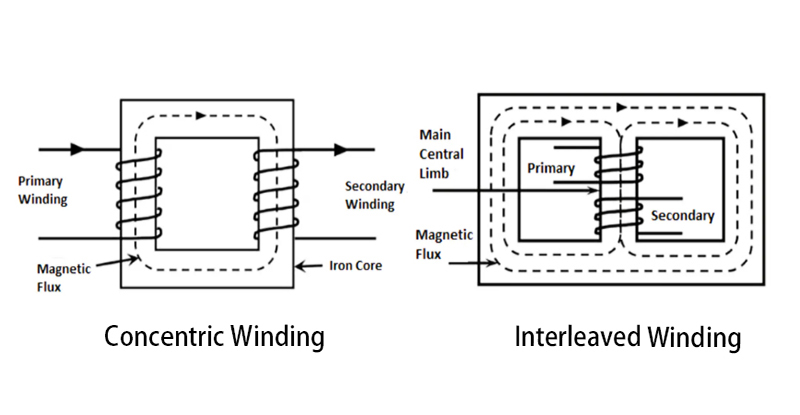

- Concentric Winding: Cylindrical layout with the low-voltage winding near the core and the high-voltage winding surrounding it. Common in small distribution transformers and compact dry-type transformer designs.

- Interleaved Winding: Alternating layers of high- and low-voltage windings, providing high mechanical strength and excellent insulation. Often used in large-capacity, high-voltage oil-immersed transformers.

- Foil Winding: Made of copper or aluminum foil for high current capacity and good heat dissipation. Frequently used in low-voltage, high-current dry-type transformers such as rectifier or welding transformers.

1.2 Insulation Material Check

High-voltage windings require thicker insulation, often using oil-impregnated paper or multiple insulation layers. Low-voltage windings, especially in dry-type transformers, may use epoxy resin or thinner insulation for better cooling.

1.3 Lead Wire Markings

Ends of windings are typically labeled (e.g., H1, H2 for high-voltage; X1, X2 for low-voltage). If unclear, electrical testing should confirm polarity and type.

2. Identification through Electrical Testing

Electrical testing offers the most precise identification of windings, suitable for both dry-type and oil-immersed transformers.

2.1 DC Resistance Test

Measure winding resistance: low-voltage windings have lower resistance due to fewer turns and thicker conductors; high-voltage windings have higher resistance due to more turns and thinner conductors.

2.2 Insulation Resistance Test

Using a megohmmeter, measure insulation resistance between windings and to ground. High-voltage to low-voltage insulation resistance should be much higher than low-voltage to ground.

2.3 Turns Ratio Test

Verify the voltage ratio matches the design (tolerance ±0.5%). Significant deviations may indicate winding deformation or incorrect connections.

2.4 No-load Test

Apply rated voltage to the low-voltage winding and measure no-load current and losses. Abnormal readings could indicate short circuits or insulation aging.

3. Identification by Labels and Parameters

Nameplates on both dry-type transformers and oil-immersed transformers provide valuable data:

- Nameplate Information: Lists rated voltages, capacity, and connection group (e.g., Yd11), indicating the winding type and function.

- Turns Ratio: Calculated from measured voltages; the side with more turns is the high-voltage winding.

4. Identification by Winding Connection Method

Recognizing the winding connection method clarifies the intended electrical function:

- Star (Y) Connection: Common for high-voltage windings, allows neutral grounding.

- Delta (Δ) Connection: Common for low-voltage windings, provides better unbalance tolerance.

- Zigzag (Z) Connection: Used for harmonic suppression and special grounding applications.

5. Special Transformer Cases

- Autotransformers: Single winding with shared sections between input and output; careful insulation verification is required.

- Multi-winding Transformers: Multiple independent windings require voltage and phase sequence testing to identify functions.

Identifying transformer windings—whether in an oil-immersed transformer or a dry-type transformer—requires combining visual inspection, label interpretation, and electrical testing. This ensures accurate identification, prevents wiring errors, and supports safe, stable operation. For critical power systems, proper winding identification is an essential part of transformer maintenance and troubleshooting.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri