Motor insulation system materials: Application and precautions of mica materials in high-voltage motors

Mica materials have the characteristics of insulation, high temperature resistance, stable physical and chemical properties, good thermal insulation, elasticity and toughness. They are widely used in the building materials industry, fire protection industry, as well as welding rods, plastics, electrical insulation, papermaking, asphalt paper, rubber, pearlescent pigments and other industrial products. The insulation of high-voltage motor windings is one of the practical applications of mica materials.

The role of mica materials in high-voltage motors

Mica materials in high-voltage motors mainly play the following roles:

1. Insulation: Mica materials in high-voltage motors have good insulation properties, which can effectively prevent electrical equipment from leakage faults and ensure the electrical safety of the equipment.

2. Sealing: Mica materials in high-voltage motors can effectively block impurities such as dust and water vapor, ensure a clean environment inside the equipment, and extend the service life of the equipment.

3. Heat dissipation: When the motor is running, a lot of heat will be generated. Mica materials in high-voltage motors can effectively dissipate heat to ensure the normal operation of the equipment.

Application of mica materials in high-voltage motors

1. Winding insulation wrapping:

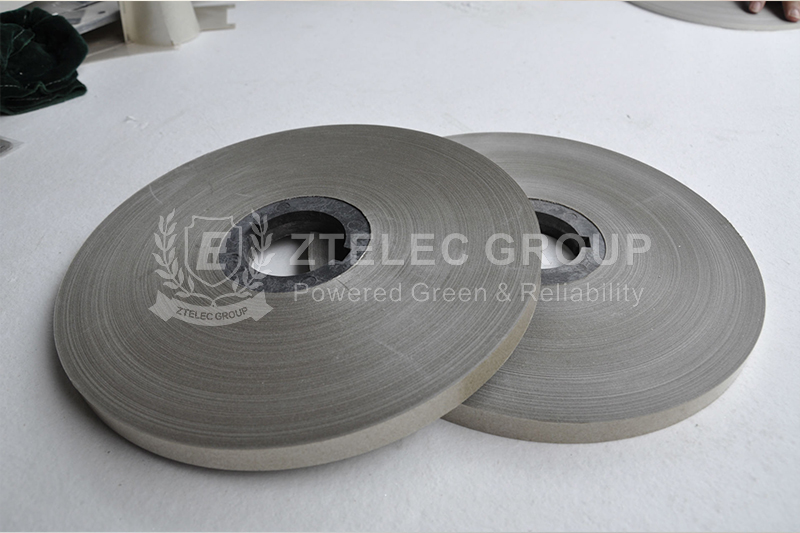

Mica materials are usually used in the form of strips for insulation wrapping of high-voltage motor coils. The wrapping process is carried out after the high-voltage motor coils are formed and gelled. The coils of motors with higher rated voltages have relatively more layers of mica materials wrapped. Mica materials can fit tightly on the surface of the coils to form a continuous insulation layer, effectively preventing current leakage and short-circuit faults.

2. Strengthening insulation performance:

In order to strengthen the insulation performance of the motor insulation and avoid the corona problem of high-voltage motor operation, the mica material is wrapped and then the resistance tape is wrapped. The straight edge of the coil is wrapped with a low resistance tape, and the end of the coil is wrapped with a high resistance tape. During the wrapping process, the interface between the high resistance tape and the low resistance tape must be controlled in place to avoid wrapping gaps. The resistance tape wrapped outside the coil can effectively improve the contact between the coil and the iron core, reduce the gap between the coil and the iron core, and play a certain protective role on the mica insulation material. During the production and processing process, if the gap between the coil and the iron core is large, necessary measures should be taken to fill the insulation.

Precautions

Storage conditions: The storage conditions of mica materials must meet the requirements to prevent failure. The requirements of specific temperature and shelf life are often not well implemented in motor manufacturers, which will cause great economic losses to the company.

Wrapping process: Mica materials are generally wrapped by manual, semi-manual, semi-mechanical and fully automatic methods. During the manual wrapping process, problems with the coil or insulation material can be discovered in time, but the tightness of the wrapping and the consistency of the overlap are difficult to grasp. When using semi-automatic and fully automatic equipment for wrapping, the wrapping efficiency is higher, but the ends of the coil can only be wrapped manually.

Immersion and baking process: During the winding immersion and baking process, especially for the vacuum pressure equipment process, the defects of the insulation wrapping process can be compensated. The resistance band wrapped outside the coil can effectively improve the contact between the coil and the core, reduce the gap, and play a certain protective role on the mica insulation material.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri