Application of G11 Epoxy Machined Components in Reactors

In fields such as nuclear power, chemical processing, and high-energy physics, reactors operate for long periods under extreme conditions, including high temperature, high pressure, high mechanical stress, and complex media environments. These conditions impose extremely stringent requirements on the safety and stability of internal structural materials. Thanks to their excellent heat resistance, electrical insulation performance, and structural strength, G11 epoxy glass fiber laminate machined components have become one of the important candidate materials for critical insulation and support parts inside reactors.

Overview of G11 Epoxy Machined Components

G11 is a high-performance laminated insulation material composed of an epoxy resin matrix reinforced with alkali-free glass fiber cloth. Compared with commonly used G10/FR4 materials, G11 can maintain stable mechanical and electrical properties even under elevated temperatures. Its thermal class can reach Class F (155 °C) or higher, making it suitable for industrial equipment with stringent thermal stability requirements.

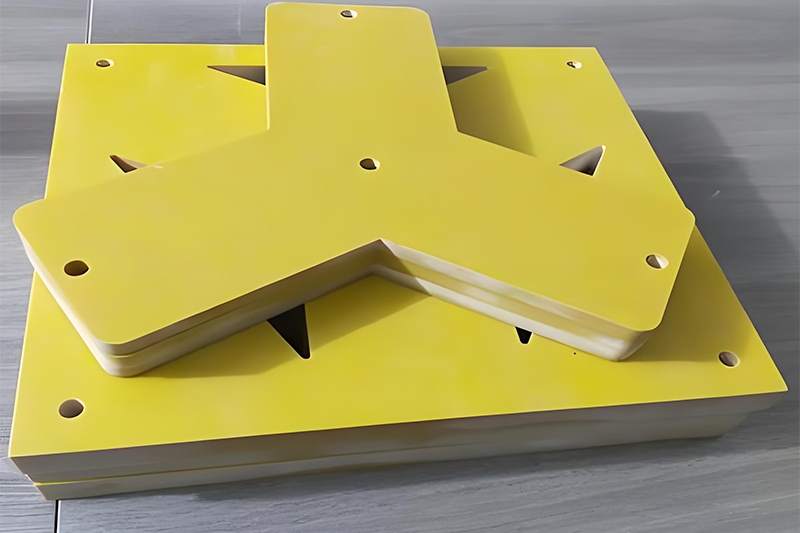

Through CNC machining, waterjet cutting, precision milling, and other processing methods, G11 can be manufactured into various high-precision customized structural components. These parts are widely used in insulation and structural support systems within reactors.

Requirements for Insulation Materials in Reactors

The operating environment of reactors is highly complex, and materials are typically required to meet the following performance criteria:

The material must withstand long-term high-temperature operation with stable thermal aging performance.

The material must provide excellent electrical insulation to prevent partial discharge and electrical breakdown.

The material must have high mechanical strength and dimensional stability to endure vibration and mechanical stress.

The material must be resistant to chemical media and radiation environments.

The material must offer good machinability to meet the customization requirements of complex structural components.

Typical Applications of G11 Epoxy Machined Components in Reactors

1.Insulating Support Structural Components

G11 epoxy machined parts are used to support conductive components, coils, or electrode structures, providing reliable electrical insulation and mechanical fixation.

2.High-Temperature Insulating Barriers and Spacers

In high-temperature areas inside reactors, G11 is used as insulating barriers or spacers to prevent current leakage and localized heat conduction.

3.Mounting Components for Coils and Electrical Assemblies

G11 epoxy machined components are employed to secure high-voltage coils, electrical modules, and other auxiliary devices, ensuring structural stability and preventing insulation failure.

4.Special Function Customized Parts

According to specific reactor designs, G11 can be machined into special-shaped parts, slotted components, positioning elements, and other customized structures to meet complex assembly requirements.

Performance Advantages of G11 Machined Components in Reactor Applications

1.Excellent Heat Resistance

In high-temperature environments, G11 machined components maintain stable dielectric strength and mechanical properties, making them suitable for long-term continuous operation.

2.Stable Electrical Insulation Performance

G11 machined components feature high volume resistivity and low dielectric loss, effectively reducing the risk of partial discharge and enhancing overall system operational safety.

3.High Mechanical Strength and Creep Resistance

Even under high-temperature and load conditions, G11 retains good bending, compressive, and impact resistance.

4.Good Machining Adaptability

G11 enables high-precision machining with clean edges and minimal delamination, meeting the strict assembly accuracy requirements of reactor applications.

Selection and Application Recommendations for G11 Epoxy Machined Parts

When selecting G11 epoxy machined parts for reactor projects, it is recommended to focus on the following key factors:

♦ Operating temperature and continuous service conditions

♦ Voltage level and insulation safety margins

♦ Mechanical loads and installation methods

♦ Exposure to chemical media or radiation

♦ Machining accuracy and structural complexity

Proper material selection and standardized machining can significantly enhance the operational reliability and service life of reactor systems.

With the development of nuclear energy and advanced industrial technologies, reactors are facing increasingly stringent requirements for material performance. Thanks to its high temperature resistance, excellent electrical insulation, high mechanical strength, and good machinability, G11 epoxy machined parts have become one of the important solutions for internal insulation and structural components in reactors. Through scientific selection and professional machining, G11 materials can provide reliable support for the long-term, safe, and stable operation of reactor systems.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri