Beech Laminated Wood vs. Birch Laminated Wood: How to Choose? The Ultimate Guide

In the manufacturing of electrical insulation structural components—especially in transformer blocks, high-voltage switchgear, and other electrical equipment—electrical laminated wood is a key material. Among them, beech and birch are the two most commonly used and best-performing base materials. When choosing between electrical beech laminated wood and electrical birch laminated wood, many engineers and procurement managers often feel unsure. This article compares the two materials across several critical dimensions to help you make the right decision.

Understanding Electrical Laminated Wood

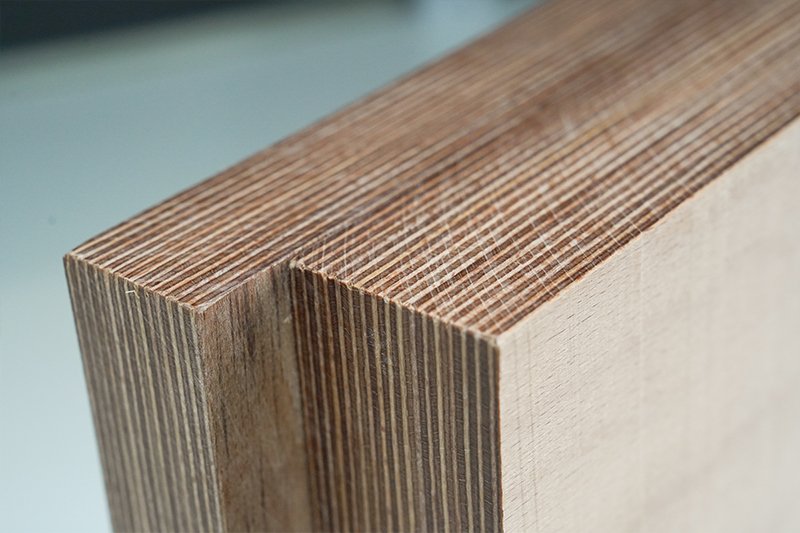

First, it is important to clarify what electrical laminated wood is. It is not ordinary wood. Instead, it is a composite material made from high-quality wood such as beech or birch, which is first rotary-cut into thin veneers, then impregnated with phenolic resin, and finally laminated under high temperature and high pressure. This manufacturing process gives it excellent mechanical strength, electrical insulation properties, and stable dimensional performance.

Beech Laminated Wood vs. Birch Laminated Wood

Both materials are excellent choices, but their characteristics and suitable applications differ. The specific differences are as follows:

1. Mechanical Properties

Mechanical performance is a key factor when selecting structural components such as blocks, spacers, and supports.

Electrical Beech Laminated Wood:

It has high density and a hard texture, with superior compressive and bending strength along the grain direction. It performs reliably in applications requiring high short-circuit electrodynamic resistance or long-term mechanical loading.

Electrical Birch Laminated Wood:

It features a uniform fiber structure and consistent mechanical properties in all directions. Its interlayer bonding strength and wear resistance are typically better than those of beech, providing stronger anti-delamination performance in high-speed or high-frequency vibration environments.

Recommendation:

If static structural components require maximum strength, choose beech.

If the environment involves dynamic loads, vibration, impact, or requires high wear resistance and anti-delamination performance, choose birch.

2. Electrical Insulation Properties

Both materials are excellent electrical insulators, but subtle differences exist due to structural variations.

Electrical Beech Laminated Wood:

Insulation performance is good overall. Although the natural pores of the wood are filled during resin impregnation, insulation uniformity may be slightly inferior to birch under extreme voltage conditions.

Electrical Birch Laminated Wood:

It has a denser and more uniform structure, allowing more thorough and even resin impregnation. This results in higher dielectric strength and more stable, predictable electrical performance, making it suitable for ultra-high-voltage and critical insulation applications.

Recommendation:

In ultra-high-voltage systems, DC converter valves, and other applications requiring highly consistent insulation performance, birch laminated wood is more widely used.

3. Machinability

Machinability: Both materials can be machined by turning, milling, drilling, grinding, and other mechanical processes. Beech has higher hardness, which causes slightly more tool wear during machining. Birch has a more uniform texture, resulting in smoother edges, fewer burrs, and a higher finished-product yield.

How to Choose? Decision Guide

Based on the comparison above, you can select efficiently according to the following application scenarios:

1. When to Prioritize Electrical Beech Laminated Wood

Application Scenarios:

Large power transformer blocks, structural support components, and other parts mainly subjected to high static compressive and bending stress.

Core Requirements:

High ultimate mechanical strength and budget control.

Voltage Level:

Suitable for medium- and high-voltage environments where insulation requirements fall within the performance range of beech laminated wood.

2. When to Prioritize Electrical Birch Laminated Wood

Application Scenarios:

Ultra-high-voltage transformers, HVDC converter transformers, reactors, high-voltage switchgear, and other fields requiring highly consistent insulation performance.

Core Requirements:

Stable and predictable electrical insulation performance, high wear resistance, and strong anti-delamination capability (especially in vibration environments).

Electrical laminated wood selection directly affects whether electrical equipment can operate safely, how stable it remains during operation, and how long it can serve.

You don’t need to look for the best material—what matters is selecting the most suitable one based on:

How it will be used in your application,

Which performance indicators matter most,

How much budget is available.

If you still have questions for your specific project, you can evaluate again according to the comparison dimensions in this article, or consult your material supplier based on the actual operating conditions of your equipment. This ensures the chosen material meets technical requirements while keeping costs under control.

- more+releated article

- 2026-01-06Beech Laminated Wood vs. Birch Laminated Wood:

- 2026-01-06Electrical Insulating Paperboard: Application

- 2026-01-06Why More Global Buyers Are Choosing Chinese-Ma

- 2026-01-05Ten Common Mistakes to Avoid When Purchasing P

- 2026-01-05Application of DDP Insulation Paper in Oil-Imm

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on