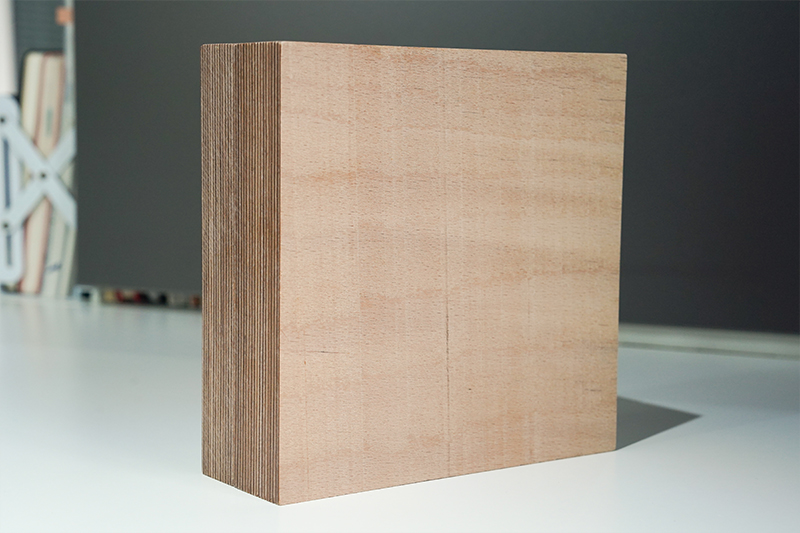

What is Beech Electrical Laminated Wood? Advantages, Disadvantages, and Applications

In the field of electrical insulation materials, beech electrical laminated wood is commonly referred to as laminated wood insulation or electrical laminated wood. It is a specially treated natural base insulation material. It uses high-quality beech wood veneers as raw materials. The veneers are first impregnated or coated with phenolic resin, then subjected to layering and curing under high temperature and high pressure conditions, ultimately resulting in board-shaped, rod-shaped, or tube-shaped materials.

Advantages of Beech Electrical Laminated Wood

♦ Excellent electrical insulation performance:

After being impregnated with resin and subjected to high-temperature curing, the insulation strength, volume resistivity, and surface resistivity of beech electrical laminated wood are at a relatively high level. It can withstand high voltages and effectively prevent current leakage and breakdown.

♦ High mechanical strength and stiffness:

Beech wood itself is hard, and through the layering and lamination process, the bending strength, compressive strength, and impact resistance of beech electrical laminated wood are even more outstanding. It is suitable for structural components that need to withstand both mechanical stress and electrical load simultaneously.

♦ Good processing performance:

Beech electrical laminated wood can undergo conventional mechanical processing such as turning, milling, drilling, planing, and grinding. Through these processing methods, it can be made into complex shapes and precise components.

♦ Stable performance in oil:

Beech electrical laminated wood is not easily penetrated by transformer insulation oil. Even if it is soaked in the insulation oil for a long time, its performance does not significantly decline, so it is suitable for oil-immersed electrical equipment.

♦ Environmentally friendly and renewable:

The main raw material of beech electrical laminated wood is wood, which belongs to a renewable resource. From the perspective of raw material sources, it has sustainability.

♦ Good damping and shock absorption effect:

Beech electrical laminated wood can absorb energy and reduce vibrations. During the operation of the equipment, it can reduce the amplitude of vibration and the generated noise.

The Shortcomings of Beech Electrical Laminated Wood

♦ Hygroscopicity:

The wood itself has hygroscopic properties. Even if the surface of beech wood is coated with resin, it will still absorb moisture from the air. In a humid environment, its insulation performance will significantly decline. Therefore, before use or after maintenance, it should be dried, and insulating paint should be applied to achieve the purpose of moisture prevention.

♦ Anisotropy:

Affected by the wood fiber structure, the mechanical and electrical properties of beech wood differ in the longitudinal and transverse directions. When designing and using it, the directionality must be considered. Otherwise, it may affect the overall strength.

♦ Susceptibility to environmental and biological influences:

When the protective layer such as insulating paint on the surface of beech wood is damaged, in a humid and hot environment, it may grow mold or be attacked by insects. However, modern production processes have significantly reduced such risks.

♦ Competition with synthetic materials:

In some high-end application fields, electrical laminated wood is gradually being replaced by epoxy glass cloth panels, DMC/SMC, etc. These synthetic materials have more balanced performance, better isotropy, and lower hygroscopicity.

The Main Application Scenarios of Beech Electrical Laminated Wood

Beech electrical laminated wood combines insulation and strength, and is mainly used in high-voltage, large-capacity electrical equipment as insulation structural components.

♦ Transformers (especially oil-immersed transformers):

Beech electrical laminated wood can be used to make winding press plates or press rings, which are used to press and fix transformer coils to prevent the coils from loosening and deforming due to electromagnetic force, while allowing them to play the roles of insulation and support.

It can also be made into insulation end rings, pads, and support rods, which are used to isolate and support coils and components with different potentials.

It can also be made into lead wire supports to support and fix high-voltage leads.

♦ High-voltage switchgear:

Beech electrical laminated wood can be used to make insulation pillars, operating rods, and connecting rods for disconnect switches. These components need to simultaneously achieve the functions of transmitting mechanical operating force and ensuring insulation to ground.

♦ Motors (large generators and motors):

In motors, beech electrical laminated wood can be used to make slot wedges to fix the coils in the iron core slots.

It can also be made into insulation pads, supports, and other components.

♦ Other electrical equipment:

In reactors, transformers, capacitors, and other equipment, beech electrical laminated wood is also used as insulation support and structural components.

Beech electrical laminated wood is a classic natural-based composite insulation material. Its core advantage is the good combination of mechanical and electrical properties, and excellent processing performance. Although it has limitations in moisture absorption and heat resistance, through process treatment and protective measures, it still occupies an important position in high-voltage electrical equipment and is one of the preferred materials for key insulation structural components.

- more+releated article

- 2026-01-06What is Beech Electrical Laminated Wood? Advan

- 2026-01-06Beech Laminated Wood vs. Birch Laminated Wood:

- 2026-01-06Electrical Insulating Paperboard: Application

- 2026-01-06Why More Global Buyers Are Choosing Chinese-Ma

- 2026-01-05Ten Common Mistakes to Avoid When Purchasing P

- 2026-01-05Application of DDP Insulation Paper in Oil-Imm

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution