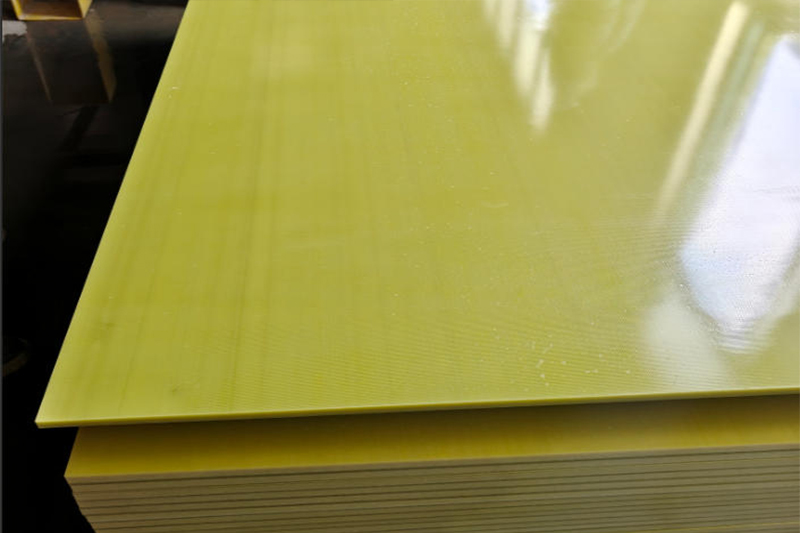

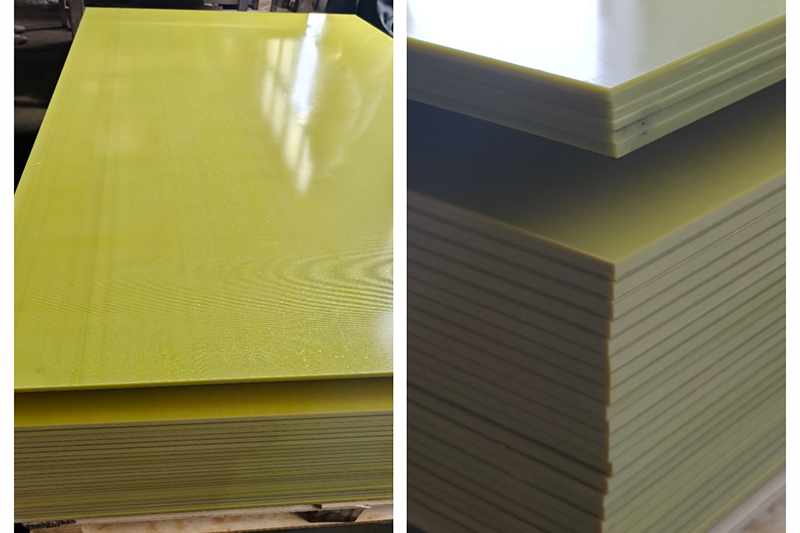

3240-B Epoxy Phenolic Glass Fiber Cloth Laminate

3240-B Epoxy Phenolic Glass Fiber Cloth Laminate is a high-performance industrial laminate. It utilizes electronic-grade alkali-free glass fiber cloth as a reinforced base, impregnated with epoxy phenolic resin, and then cured using a high-temperature, high-pressure process. The technical parameters and quality requirements of this material are clearly defined in the GB/T 1303.2 standard. It is currently widely used in insulating structural components in the electrical, electronic, and mechanical fields.

3240-B Laminate Features and Advantages

1. High Mechanical Strength

The reinforcement of the glass fiber cloth gives 3240-B laminate high flexural, impact, and shear strength. It can be used as a structural component, such as a frame and gasket in transformers and motors, to withstand significant mechanical stress.

2. Stable Electrical Insulation

3240-B laminate maintains excellent insulation properties in both dry and humid environments. It offers high insulation resistance, high dielectric strength, and excellent arc resistance, making it suitable for electrical products such as high-voltage switchgear, distribution cabinets, and insulating partitions.

3. Excellent Heat Resistance

As a Class F insulation material, 3240-B laminate has a long-term operating temperature of up to 155°C. Its mechanical and electrical performance degradation is minimal in high-temperature environments, ensuring stable operation of equipment in harsh environments.

4. Excellent Chemical Resistance

3240-B laminate effectively resists common chemicals such as acids, alkalis, solvents, and transformer oil, effectively preventing corrosion or dissolution, thereby extending equipment life.

5. Easy Machining

Compared to some high-performance plastics, 3240-B laminate is easier to process, including cutting, drilling, turning, and milling. It can be formed into parts with various complex shapes to meet diverse application requirements.

Common Applications of 3240-B Laminate

Electrical and Power Industry: Transformer insulation bobbins, busbar supports, high-voltage switchgear partitions, cable racks, and distribution boards.

Electronic Equipment Industry: PCB drilling pads, electronic component insulation bases, test fixtures, and FPC reinforcement plates.

Mechanical Equipment Industry: Insulation and wear-resistant components for mechanical parts such as gears, bearings, sliders, and bushings.

Rail Transit Industry: Insulation components in locomotive control systems and traction converters.

How to choose the right 3240-B laminate?

1. Clearly define your specifications

Precisely provide the required sheet thickness, length, width, and tolerance range. Common thicknesses range from 0.5mm to 50mm and select the appropriate sheet material based on your specific needs.

2. Select a reliable supplier

Preferably choose manufacturers or distributors that are GB/T certified, have consistent quality, and can provide material certification to ensure product quality compliance.

3. Processing Considerations

Tool Selection: Use carbide or diamond tools for smoother machined surfaces.

Cooling: Use coolant during machining to reduce dust, extend tool life, and improve machining quality.

Safety precautions: Fiberglass dust generated during machining can irritate the respiratory tract and skin. Wear a dust mask, goggles, and gloves, and maintain good ventilation in the work area.

FAQs

Q1: What is the difference between 3240-B and FR-4 epoxy fiberglass sheets?

A1: Both have similar base materials, but differ in their resin systems and applications. FR-4 is primarily used in printed circuit boards (PCBs), requiring higher copper foil adhesion and dielectric constant. 3240-B is primarily used in insulating structural components, prioritizing mechanical strength and insulation stability under complex operating conditions.

Q2: Can 3240-B sheets be treated for moisture resistance?

A2: Yes. The sheet itself has a certain degree of moisture resistance. If exposed to extremely humid environments, the finished product can be impregnated with insulating varnish or coated to further enhance moisture resistance and insulation reliability.

Q3: Where can I purchase genuine 3240-B laminates?

A3: You can purchase through professional industrial material distributors, B2B platforms (such as Alibaba), or directly contact a qualified laminate manufacturer.

- more+releated article

- 2026-01-063240-B Epoxy Phenolic Glass Fiber Cloth Lamina

- 2026-01-06Are Three-Phase Isolation Dry-Type Transformer

- 2026-01-06G10 Epoxy Sheet: Choosing the Right Specificat

- 2026-01-06What are The Advantages of Phenolic Cotton Clo

- 2026-01-0630kVA Three-Phase Isolation Dry-Type Transform

- 2026-01-06Phenolic Cotton Cloth Tube Factory Direct Sale

- 2026-01-06Phenolic cotton cloth tube VS Epoxy tube: How

- 2026-01-06Performance and Price Comparison of 10kV Oil-I

- 2026-01-06Key Applications of Fibra tubes in Motors and

- 2026-01-06From 30kVA to 31500kVA: Key Points for Capacit