Key Applications of Fibra tubes in Motors and Transformers

In the design and manufacture of motors and transformers, the choice of insulation material directly impacts the reliability, longevity, and safety of the equipment. Fibra tubes are a classic industrial material. Their excellent electrical insulation, high mechanical strength, and heat resistance have made them an essential component in motors and transformers. This article will detail the key applications of fibra tube in such equipment and how they can improve performance and efficiency.

What are fibra tubes and what are their characteristics?

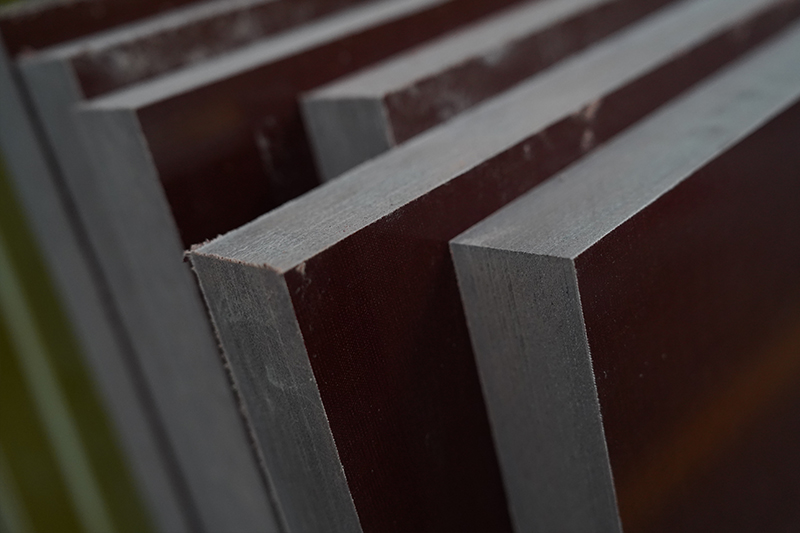

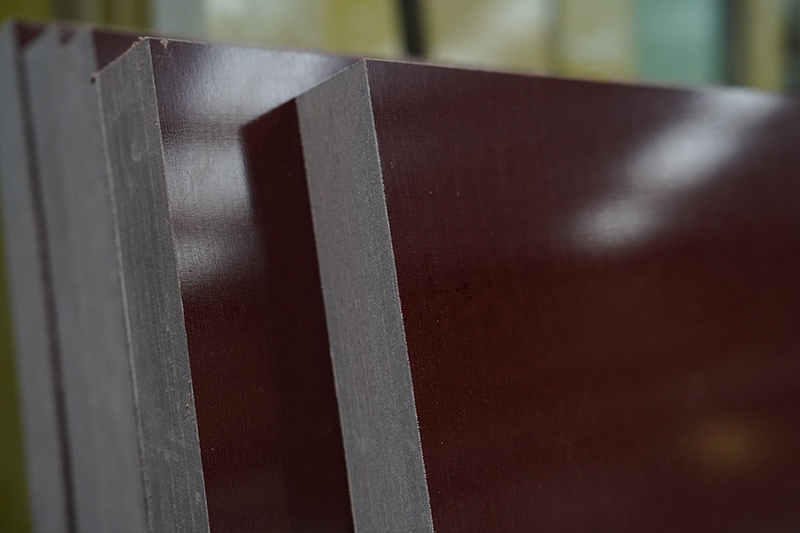

Fibra tubes are tubular insulation materials made by soaking cotton in phenolic resin and then heat-curing them. They combine the flexibility of cotton with the high strength and chemical resistance of phenolic resin. Their key features are as follows:

High insulation resistance: They effectively prevent current leakage, ensuring the normal and safe operation of the equipment.

Mechanical durability: They are impact-resistant and abrasion-resistant, and can be used in high-speed rotation environments.

Heat and moisture resistance: They maintain stable performance even in high-temperature and humid conditions. Easy to process: They can be cut and drilled to meet customized usage needs.

How are fibra tubes used in motors?

1. Insulation and Support

In the stator and rotor of a motor, fibra tubes are often used as the insulation framework for the coils. This prevents contact between the windings and metal components, reducing the possibility of short circuits. Furthermore, their high mechanical strength allows them to withstand electromagnetic forces and equipment vibration, extending motor life.

2. InsulatioC Motor Shaft

They can be applied to the motor shaft to insulate it, preventing corrosion and damage to components caused by shaft currents. They are particularly suitable for use in variable-frequency drive motors. Furthermore, as protective sleeves, they reduce friction between components and operating noise, ensuring smoother motor rotation.

3. Commutator Insulation and Brush Holders

In DC motors, fibra tubes are used to insulate the commutator, ensuring stable current transmission. They are also arc-resistant, making them ideal for use as brush holders.

How are fibra tubes used in transformers?

1. Insulating and isolating windings

Fibra tubes are often used to insulate transformer windings between layers, preventing short circuits between turns and improving the transformer's electrical efficiency. They are also oil-resistant and can be used in oil-immersed transformers to mitigate the effects of insulating oil aging.

2. Supporting and securing internal structures

Fibra tubes serve as support tubes within the transformer, securing leads and various components to prevent displacement. In dry-type transformers, they also help dissipate heat, improving thermal management.

3. Protecting lead wires and forming insulating sleeves

Fibra tubes can be used as insulating sleeves for transformer lead wires, protecting them from external factors such as dust and moisture. Furthermore, they are flame-retardant, meet safety standards, and reduce fire risks.

Why choose fibra tubes?

Cost-Effective: Compared to high-end composite materials, fibra tube costs less while providing reliable performance.

Enhanced Environmental Adaptability: Through modifications like mildew-proofing and chemical-resistant coatings, it can be used in harsh operating environments.

Environmentally Friendly Recycling: Made from cotton cloth, it's easily recyclable and aligns with the trend toward green manufacturing.

In recent years, motors and transformers have become increasingly efficient and compact. Fibra tube has also been improved through processes like vacuum impregnation, further enhancing its insulation rating. For example, its use in new energy vehicle drive motors and wind turbine transformers ensures stable operation under high-voltage and high-frequency operating conditions.

Although a traditional material, fibra tube plays an irreplaceable role in motors and transformers. From insulation protection to structural support, it ensures the proper operation of power equipment. For equipment designers and engineers, the appropriate use of fibra tube offers a balance between performance, cost, and reliability.

- more+releated article

- 2026-01-06Key Applications of Fibra tubes in Motors and

- 2026-01-06From 30kVA to 31500kVA: Key Points for Capacit

- 2026-01-06The Application of Glass Fiber Wounded Pipe in

- 2026-01-06DDP Insulating Paper Manufacturers, Suppliers,

- 2026-01-06Industrial Grid Upgrade Essential: 23kV 3500kV

- 2026-01-06Energy-Saving Dry-Type Distribution Transforme

- 2026-01-06What is Beech Electrical Laminated Wood? Advan

- 2026-01-06Beech Laminated Wood vs. Birch Laminated Wood:

- 2026-01-06Electrical Insulating Paperboard: Application

- 2026-01-06Why More Global Buyers Are Choosing Chinese-Ma