G10 Epoxy Sheet: Choosing the Right Specifications and Sizes

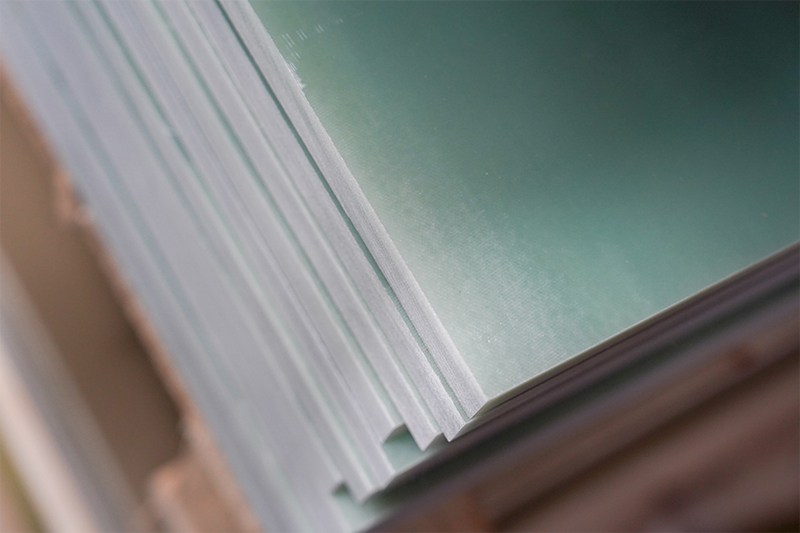

G10 epoxy sheet is a popular choice for engineers and manufacturers seeking durable, high-performance insulation materials in the industrial sector.

However, many may overlook the importance of choosing the right specifications and sizes for G10 epoxy sheet, ensuring its full performance, controlling project costs, and ensuring project success. Incorrect selections can lead to material waste, increased processing complexity, and even unusable final products.

This article will explain in detail how to select the appropriate G10 epoxy sheet specifications and sizes for your specific application, helping you make the right choice.

Identifying Core Specifications

Specifications encompass more than just size. They encompass a range of key parameters that determine G10 epoxy sheet performance. The following are key specifications to focus on:

1. Thickness

Thickness is the first factor to consider when selecting G10 epoxy sheet, as it directly impacts the mechanical strength and insulation capabilities of the component.

Common Range: G10 sheet thicknesses range widely, typically from 0.1mm (ultra-thin sheets) to 50mm (extra-thick sheets).

Selection Method:

Electrical Insulation: If G10 epoxy sheet is primarily used for electrical isolation, select a sheet thick enough based on the actual operating voltage to ensure a safe distance. For low-voltage applications like circuit boards, a thickness of 1-3mm is generally sufficient. However, for high-voltage environments, thicker sheet is required.

Structural Support: If G10 epoxy sheet is used for structural components such as brackets and baffles, the required thickness should be calculated based on the component's load-bearing and stress-bearing requirements. Thicker sheet generally supports greater weight.

Processing and Cost: Thinner G10 sheet is easier to cut and bend (within a limited range) and has lower procurement costs. Thicker sheet, on the other hand, requires more time to process and is more expensive.

2. Dimensions (Length × Width)

The standard dimensions of G10 epoxy sheet affect material utilization and waste.

Common Standard Dimensions:

1020mm × 1220mm

1220mm×1220mm

1220mm × 2440mm

Selection Method:

If your product is large, choosing large-sized G10 epoxy sheet can reduce the number of assembly steps. If the component itself is small, it's often more cost-effective to purchase standard large sheets and cut them yourself.

Most suppliers offer custom cutting services for G10 epoxy sheet. If you don't have large-scale cutting equipment, purchasing custom pieces close to the final product size can save time, reduce material waste, and prevent manufacturing errors.

3. Grade and Color

G10 epoxy sheet has generally stable performance, but there are subtle differences in grade and color.

Color: The most common colors for G10 epoxy sheet are natural, aqua, and black. Color generally does not affect its core mechanical and electrical properties, but it may vary slightly due to the dye or resin used in production. Black is often used in applications requiring UV resistance.

Grade: When purchasing G10 epoxy sheet, be sure to confirm whether it is FR-4 or G10 grade. FR-4 is the flame-retardant version of G10 and is currently the most common type. It meets the UL94 V-0 flame retardancy standard. For most electrical and electronic applications, FR-4 is the preferred grade.

Select specifications and sizes based on the application scenario

The following common application scenarios will help you better determine your G10 epoxy board selection:

Application 1: PCB Drilling Pad

Recommended thickness: 1.5mm-3.0mm. This G10 epoxy board provides adequate support during drilling, preventing the drill from penetrating the workbench. It also absorbs impact without excessive thickness, ensuring drilling accuracy and extending the life of the drill.

Recommended size: This size typically matches the tabletop dimensions of the PCB production equipment, with 1220mm x 1220mm being a common size. This size can be cut later based on actual needs.

Application 2: Electrical Insulation Spacers or Bodies

Recommended thickness: 0.5mm-2.0mm. This type of G10 epoxy board is commonly used for insulation between transformer and motor coils. While it doesn't typically require excessive thickness, it does require high flatness and consistency.

Recommended size: Custom precision engraving is generally required. You can directly provide your supplier with part drawings and have them machine the final shape, ensuring precision and production efficiency.

Application 3: Mechanical Structural Parts (e.g., gears, bearing housings)

Recommended Thickness: 5mm-20mm+. These G10 epoxy sheet parts are subject to sustained mechanical forces, so thickness is a critical parameter. You must calculate the appropriate thickness based on the actual loads the part will bear.

Recommended Size: Depending on the part size, you can purchase standard G10 epoxy sheet and machine it yourself, or you can directly order custom rods or tubes. G10 epoxy sheet can also be made into round and square rods, suitable for lathe machining.

Choosing G10 epoxy sheet doesn't have to be complicated. Simply clarify your application and then consider key parameters such as thickness, size, and grade to select the right product, avoiding waste and hassle.

- more+releated article

- 2026-01-06G10 Epoxy Sheet: Choosing the Right Specificat

- 2026-01-06What are The Advantages of Phenolic Cotton Clo

- 2026-01-0630kVA Three-Phase Isolation Dry-Type Transform

- 2026-01-06Phenolic Cotton Cloth Tube Factory Direct Sale

- 2026-01-06Phenolic cotton cloth tube VS Epoxy tube: How

- 2026-01-06Performance and Price Comparison of 10kV Oil-I

- 2026-01-06Key Applications of Fibra tubes in Motors and

- 2026-01-06From 30kVA to 31500kVA: Key Points for Capacit

- 2026-01-06The Application of Glass Fiber Wounded Pipe in

- 2026-01-06DDP Insulating Paper Manufacturers, Suppliers,