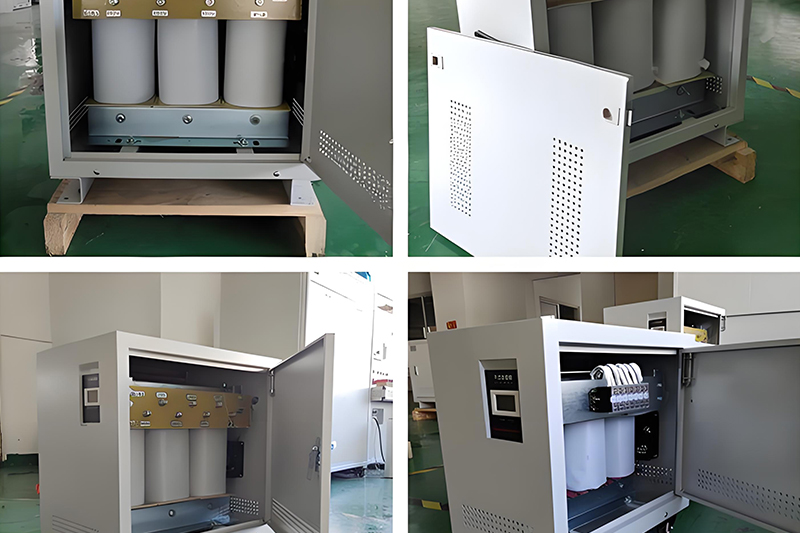

30kVA Three-Phase Isolation Dry-Type Transformer Load Capacity Analysis: Is Efficiency ≥ 95% Realistic?

30kVA three-phase isolation dry-type transformers play a vital role in industrial, commercial, and renewable energy systems. They supply stable power for precision equipment and ensure reliable voltage conversion. Among their specifications, one frequently noted performance indicator is “efficiency ≥ 95%.” But does this figure truly reflect real-world performance, and how does it relate to load capacity? This article provides a detailed technical analysis to answer these questions.

Understanding Transformer Efficiency and Load Capacity

Transformer efficiency (η) represents the ratio of the transformer’s output active power (P₂) to its input power (P₁), expressed as:

η = (P₂ / P₁) × 100%

Higher efficiency means lower losses and better energy performance. The load capacity refers to the maximum power a transformer can continuously deliver without overheating or damage. For a 30kVA transformer, 30 kVA is the rated apparent power, but the actual usable power (kW) depends directly on its efficiency and power factor.

Conclusion: For modern high-quality dry-type transformers, an efficiency of ≥95% is not only realistic but also conservative. In practice, advanced models can achieve efficiencies up to 97% or more.

Why “Efficiency ≥ 95%” Is Technically Achievable

1. Technological Advancements and Materials

Core Materials: Today’s dry-type transformers often use cold-rolled silicon steel or amorphous alloy cores, which feature high magnetic permeability and low specific iron loss, minimizing no-load (core) losses.

Winding Materials: Premium-grade oxygen-free copper windings offer lower resistivity and higher conductivity compared to aluminum, significantly reducing load (copper) losses.

2. Design and Cooling Advantages of Dry-Type Transformers

Compared with oil-immersed transformers, epoxy resin-cast dry-type transformers provide superior heat dissipation and insulation. Their optimized structural design allows higher current densities and lower total energy losses, even under heavy load conditions.

3. Compliance with Global Energy Efficiency Standards

According to IEC and national Class I / Class II energy efficiency standards, a 30kVA three-phase dry-type transformer typically maintains a stable efficiency between 95% and 97%. Some advanced designs exceed 97% at optimal load, confirming that “efficiency ≥ 95%” is a valid benchmark, not just a marketing claim.

Efficiency and Its Direct Impact on Load Capacity

Efficiency directly affects how much of the 30kVA apparent power is converted into usable active power. Let’s illustrate this relationship:

Example: Assume a 30kVA transformer with a load power factor of 0.8 and an efficiency of 95%.

• Apparent Power = 30 kVA • Output Active Power (P₂) = 30 × 0.8 = 24 kW • Required Input Power (P₁) = 24 / 0.95 ≈ 25.26 kW • Total Losses = 25.26 – 24 = 1.26 kW

This means the transformer’s safe continuous load should remain slightly below 24 kW to prevent overheating. Lower efficiency leads to more heat generation, accelerating insulation aging and reducing operational reliability. By contrast, a transformer with 95% efficiency produces far less heat than one with 90%, offering greater overload tolerance and longer service life.

Key Factors Influencing Efficiency and Load Performance

1. Load Factor

Transformers do not maintain peak efficiency at all load levels. The optimal efficiency zone is usually between 40% and 60% of rated load. Operating at full or very light loads for long periods can reduce total energy efficiency.

2. Load Power Factor

When the load power factor is low (e.g., 0.7), even if the apparent power is 30kVA, the real output power (kW) decreases, lowering overall efficiency. Improving the load-side power factor is essential to fully utilize transformer capacity.

3. Harmonic Distortion

Power electronic equipment such as inverters and rectifiers generate harmonics, which increase copper and iron losses and raise operating temperatures. High harmonic distortion can force transformer derating to prevent overheating.

4. Ambient Temperature and Cooling Conditions

Ambient ventilation directly affects transformer heat dissipation. In high-temperature environments, transformers must reduce load to prevent excessive temperature rise, protecting insulation and ensuring safety.

The 30kVA three-phase isolation dry-type transformer can realistically achieve efficiency ≥95%, provided it uses modern materials, optimized design, and proper load management. Efficiency directly influences load capacity, thermal stability, and overall operational lifespan. Understanding this relationship helps engineers select and operate transformers for maximum reliability and energy savings in industrial and renewable power systems.

- more+releated article

- 2026-01-0630kVA Three-Phase Isolation Dry-Type Transform

- 2026-01-06Phenolic Cotton Cloth Tube Factory Direct Sale

- 2026-01-06Phenolic cotton cloth tube VS Epoxy tube: How

- 2026-01-06Performance and Price Comparison of 10kV Oil-I

- 2026-01-06Key Applications of Fibra tubes in Motors and

- 2026-01-06From 30kVA to 31500kVA: Key Points for Capacit

- 2026-01-06The Application of Glass Fiber Wounded Pipe in

- 2026-01-06DDP Insulating Paper Manufacturers, Suppliers,

- 2026-01-06Industrial Grid Upgrade Essential: 23kV 3500kV

- 2026-01-06Energy-Saving Dry-Type Distribution Transforme