What Is the Price Range of Phenolic Cotton Cloth Laminates?

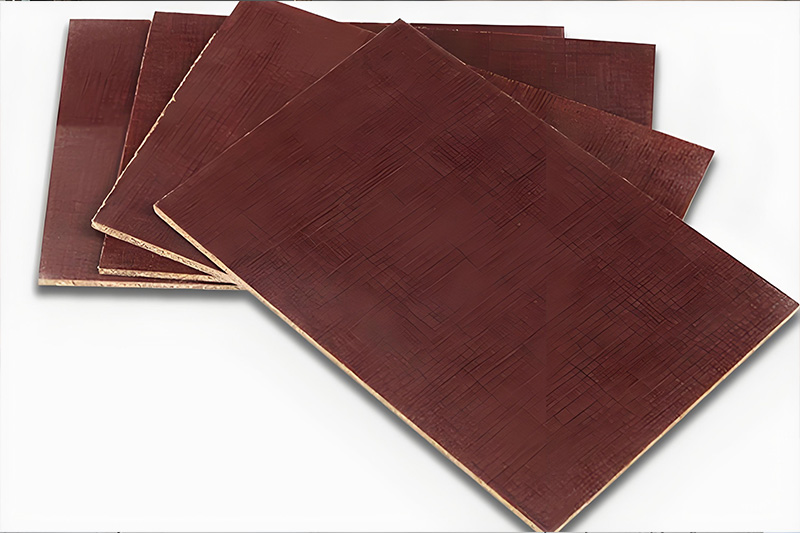

Phenolic cotton cloth laminates (also known as phenolic fabric laminated sheets) are high-performance composite materials widely used in electrical insulation, mechanical manufacturing, and the electronics industry. Their pricing has always been a key concern for procurement professionals. This article provides a systematic overview of the market price range, factors influencing pricing, and purchasing strategies to support informed decision-making for enterprises.

Price Range of Phenolic Cotton Cloth Laminates

According to current domestic and international market trends, the pricing structure for phenolic cotton cloth laminates is as follows:

By weight: The average market price typically ranges from 15 RMB/kg to 40 RMB/kg, depending on the material's performance and specifications.

By standard sheet size: For common sizes such as 1020mm × 2040mm, the price generally falls between 200 RMB/sheet and 800 RMB/sheet. Custom specifications or special-performance sheets will be priced higher accordingly.

|

Sheet Type |

Thickness Range |

Reference Price (RMB/sheet) |

|

Standard phenolic laminate |

3mm–10mm |

200–400 |

|

Medium-thickness industrial sheet |

12mm–30mm |

400–600 |

|

Extra-thick custom sheet |

≥40mm |

600 and above |

Note: Actual prices may vary based on raw material costs, brand premiums, manufacturing processes, and other market factors. The above data is for reference only.

Factors Influencing the Price Fluctuations

1.Raw Material Costs

Phenolic resin and high-quality cotton fabric are the core raw materials used in the production of these laminates. The market price of phenolic resin—often affected by the cyclical fluctuations in the petrochemical industry—directly impacts the final pricing of the laminates.

2.Specification Parameters

Thickness and Size: The thicker and larger the sheet, the more raw material is consumed and the greater the processing complexity. This can lead to a price increase of 30% to 50%.

Processing Precision: Custom processes such as CNC precision machining, special-shaped cutting, and surface treatments can raise costs by 20% to 40%.

3.Quality Certifications and Brand Value

Products that have obtained international certifications such as UL, ROHS, and REACH are typically 15% to 30% more expensive than uncertified ones. However, they offer superior performance in terms of electrical insulation, heat resistance, and mechanical strength.

4.Application-Specific Requirements

Standard Industrial Applications: For general industrial uses, such as motor insulation structures, standard laminates are sufficient and typically fall within the mid-to-low price range.

High-End Applications: In sectors such as high-voltage electrical equipment, aerospace, or defense, where high heat resistance and insulation grades are required, laminate prices can be 2 to 3 times higher than standard materials.

Price Differences Across Typical Application Scenarios

|

Application Area |

Performance Requirements |

Price Range Characteristics |

|

Motor insulation structures |

Basic insulation performance |

Moderate pricing (200–400 RMB/sheet) |

|

High-temperature transformers |

Heat resistance ≥155°C (Class F) |

Relatively high pricing (400–600 RMB/sheet) |

|

Precision electronic fixtures |

Machining accuracy ±0.1mm |

Includes custom processing fees; total cost increases by 20% |

|

Automation equipment templates |

Wear resistance + high strength |

Mid-to-high-end materials recommended (500–800 RMB/sheet) |

Procurement Strategy and Key Considerations

· Accurate Requirement Positioning: Clearly define the application environment (temperature, humidity, voltage level) and performance indicators to avoid unnecessary costs from over-specification.

· Supplier Selection: Prioritize manufacturers with ISO certifications and over 10 years of production experience to ensure product consistency and reliable lead times.

· Quotation Details Review: Carefully check whether the quotation includes secondary processing fees, logistics costs, and taxes to avoid hidden expenses.

· Bulk Purchase Advantages: For orders of 50 sheets or more, negotiate for a 5%–10% discount, which is ideal for long-term projects.

The question“What is the price of phenolic cotton cloth laminates?” doesn’t have a single fixed answer. Its pricing system is a comprehensive reflection of material costs, processing complexity, and quality requirements. For industrial procurement, the true value lies in cost-performance balance—acquiring products that match the usage scenario at a reasonable price. To achieve this, it’s essential to purchase from reputable sources, define technical specifications clearly, and compare overall service offerings (e.g., sample testing, after-sales support). Only then can you optimize both cost control and performance assurance.

- more+releated article

- 2026-01-04Common Power Transformer Faults: Causes, Solut

- 2025-12-312026 New Year Holiday Notice

- 2025-12-31Operation, Maintenance, and Service Life Manag

- 2025-12-30How to Select a 100 kVA–500 kVA Distribution

- 2025-12-29The Impact of NHN NMN Composite Insulation on

- 2025-12-26Practical Application of GPO-3 Insulation Boar

- 2025-12-2510kV Transformer Replacement Timeline: Install

- 2025-12-25Low Smoke EN45545 GPO3 UPGM203 Laminated Board

- 2025-12-24Merry Christmas — ZTelecgroup Christmas Cele

- 2025-12-24How to Select a Suitable 50kVA–500kVA Distri